Silver nanoparticle

| Part of a series of articles on |

| Nanomaterials |

|---|

|

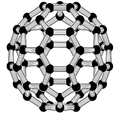

| Carbon nanotubes |

| Other fullerenes |

| Nanoparticles |

|

Silver nanoparticles are nanoparticles of silver of between 1 nm and 100 nm in size.[1] While frequently described as being 'silver' some are composed of a large percentage of silver oxide due to their large ratio of surface-to-bulk silver atoms. Numerous shapes of nanoparticles can be constructed depending on the application at hand. Commonly used are spherical silver nanoparticles but diamond, octagonal and thin sheets are also popular.[1]

Their extremely large surface area permits the coordination of a vast number of ligands. The properties of silver nanoparticles applicable to human treatments are under investigation in laboratory and animal studies, assessing potential efficacy, toxicity, and costs.

Synthetic methods

Wet chemistry

The most common methods for nanoparticle synthesis fall under the category of wet chemistry, or the nucleation of particles within a solution. This nucleation occurs when a silver ion complex, usually AgNO3 or AgClO4, is reduced to colloidal silver in the presence of a reducing agent. When the concentration increases enough, dissolved metallic silver ions bind together to form a stable surface. The surface is energetically unfavorable when the cluster is small, because the energy gained by decreasing the concentration of dissolved particles is not as high as the energy lost from creating a new surface.[2] When the cluster reaches a certain size, known as the critical radius, it becomes energetically favorable, and thus stable enough to continue to grow. This nucleus then remains in the system and grows as more silver atoms diffuse through the solution and attach to the surface [3] When the dissolved concentration of atomic silver decreases enough, it is no longer possible for enough atoms to bind together to form a stable nucleus. At this nucleation threshold, new nanoparticles stop being formed, and the remaining dissolved silver is absorbed by diffusion into the growing nanoparticles in the solution.

As the particles grow, other molecules in the solution diffuse and attach to the surface. This process stabilizes the surface energy of the particle and blocks new silver ions from reaching the surface. The attachment of these capping/stabilizing agents slows and eventually stops the growth of the particle.[4] The most common capping ligands are trisodium citrate and polyvinylpyrrolidone (PVP), but many others are also used in varying conditions to synthesize particles with particular sizes, shapes, and surface properties.[4][5]

There are many different wet synthesis methods, including the use of reducing sugars, citrate reduction, reduction via sodium borohydride,[6] the silver mirror reaction,[7] the polyol process,[8] seed-mediated growth,[9] and light-mediated growth.[10] Each of these methods, or a combination of methods, will offer differing degrees of control over the size distribution as well as distributions of geometric arrangements of the nanoparticle.[11]

A new, very promising wet-chemical technique was found by Elsupikhe et al. (2015).[12] They have developed a green ultrasonically-assisted synthesis. Under ultrasound treatment, silver nanoparticles (AgNP) are synthesized with κ-carrageenan as a natural stabilizer. The reaction is performed at ambient temperature and produces silver nanoparticles with fcc crystal structure without impurities. The concentration of κ-carrageenan is used to influence particle size distribution of the AgNPs.[13]

Monosaccharide reduction

There are many ways silver nanoparticles can be synthesized; one method is through monosaccharides. This includes glucose, fructose, maltose, maltodextrin, etc. but not sucrose. It is also a simple method to reduce silver ions back to silver nanoparticles as it usually involves a one-step process,.[14] There have been methods that indicated that these reducing sugars are essential to the formation of silver nanoparticles. Many studies indicated that this method of green synthesis, specifically using Cacumen platycladi extract, enabled the reduction of silver. Additionally, the size of the nanoparticle could be controlled depending on the concentration of the extract. The studies indicate that the higher concentrations correlated to an increased number of nanoparticles.[14] Smaller nanoparticles were formed at high pH levels due to the concentration of the monosaccharides.

Another method of silver nanoparticle synthesis includes the use of reducing sugars with alkali starch and silver nitrate. The reducing sugars have free aldehyde and ketone groups, which enable them to be oxidized into gluconate.[15] The monosaccharide must have a free ketone group because in order to act as a reducing agent it first undergoes tautomerization. In addition, if the aldehydes are bound, it will be stuck in cyclic form and cannot act as a reducing agent. For example, glucose has an aldehyde functional group that is able to reduce silver cations to silver atoms and is then oxidized to gluconic acid.[16] The reaction for the sugars to be oxidized occurs in aqueous solutions. The capping agent is also not present when heated.

Citrate reduction

An early, and very common, method for synthesizing silver nanoparticles is citrate reduction. This method was first recorded by M. C. Lea, who successfully produced a citrate-stabilized silver colloid in 1889.[17] Citrate reduction involves the reduction of a silver source particle, usually AgNO3 or AgClO4, to colloidal silver using trisodium citrate, Na3C6H5O7.[18] The synthesis is usually performed at an elevated temperature (~100 °C) to maximize the monodispersity (uniformity in both size and shape) of the particle. In this method, the citrate ion traditionally acts as both the reducing agent and the capping ligand,[18] making it a useful process for AgNP production due to its relative ease and short reaction time. However, the silver particles formed may exhibit broad size distributions and form several different particle geometries simultaneously.[17] The addition of stronger reducing agents to the reaction is often used to synthesize particles of a more uniform size and shape.[18]

Reduction via sodium borohydride

The synthesis of silver nanoparticles by sodium borohydride (NaBH4) reduction occurs by the following reaction:[19]

- Ag+ + BH4- + 3H2O →Ag0 +B(OH)3 +3.5H2

The reduced metal atoms will form nanoparticle nuclei. Overall, this process is similar to the above reduction method using citrate. The benefit of using sodium borohydride is increased monodispersity of the final particle population. The reason for the increased monodispersity when using NaBH4 is that it is a stronger reducing agent than citrate. The impact of reducing agent strength can be seen by inspecting a LaMer diagram which describes the nucleation and growth of nanoparticles.[20]

When silver nitrate (AgNO3) is reduced by a weak reducing agent like citrate, the reduction rate is lower which means that new nuclei are forming and old nuclei are growing concurrently. This is the reason that the citrate reaction has low monodispersity. Because NaBH4 is a much stronger reducing agent, the concentration of silver nitrate is reduced rapidly which shortens the time during which new nuclei form and grow concurrently yielding a monodispersed population of silver nanoparticles.

Particles formed by reduction must have their surfaces stabilized to prevent undesirable particle agglomeration (when multiple particles bond together), growth, or coarsening. The driving force for these phenomena is the minimization of surface energy (nanoparticles have a large surface to volume ratio). This tendency to reduce surface energy in the system can be counteracted by adding species which will adsorb to the surface of the nanoparticles and lowers the activity of the particle surface thus preventing particle agglomeration according to the DLVO theory and preventing growth by occupying attachment sites for metal atoms. Chemical species that adsorb to the surface of nanoparticles are called ligands. Some of these surface stabilizing species are: NaBH4 in large amounts,[19] poly(vinyl pyrrolidone) (PVP),[21] sodium dodecyl sulfate (SDS),[19][21] and/or dodecane thiol.[22]

Once the particles have been formed in solution they must be separated and collected. There are several general methods to remove nanoparticles from solution, including evaporating the solvent phase[22] or the addition of chemicals to the solution that lower the solubility of the nanoparticles in the solution.[23] Both methods force the precipitation of the nanoparticles.

Polyol process

The polyol process is a particularly useful method because it yields a high degree of control over both the size and geometry of the resulting nanoparticles. In general, the polyol synthesis begins with the heating of a polyol compound such as ethylene glycol, 1,5-pentanediol, or 1,2-propylene glycol7. An Ag+ species and a capping agent are added (although the polyol itself is also often the capping agent). The Ag+ species is then reduced by the polyol to colloidal nanoparticles.[24] The polyol process is highly sensitive to reaction conditions such as temperature, chemical environment, and concentration of substrates.[25][26] Therefore, by changing these variables, various sizes and geometries can be selected for such as quasi-spheres, pyramids, spheres, and wires.[11] Further study has examined the mechanism for this process as well as resulting geometries under various reaction conditions in greater detail.[8][27]

Seed-mediated growth

Seed-mediated growth is a synthetic method in which small, stable nuclei are grown in a separate chemical environment to a desired size and shape. Seed-mediated methods consist of two different stages: nucleation and growth. Variation of certain factors in the synthesis (e.g. ligand, nucleation time, reducing agent, etc.),[28] can control the final size and shape of nanoparticles, making seed-mediated growth a popular synthetic approach to controlling morphology of nanoparticles.

The nucleation stage of seed-mediated growth consists of the reduction of metal ions in a precursor to metal atoms. In order to control the size distribution of the seeds, the period of nucleation should be made short for monodispersity. The LaMer model illustrates this concept.[29] Seeds typically consist small nanoparticles, stabilized by a ligand. Ligands are small, usually organic molecules that bind to the surface of particles, preventing seeds from further growth. Ligands are necessary as they increase the energy barrier of coagulation, preventing agglomeration. The balance between attractive and repulsive forces within colloidal solutions can be modeled by DLVO theory.[30] Ligand binding affinity, and selectivity can be used to control shape and growth. For seed synthesis, a ligand with medium to low binding affinity should be chosen as to allow for exchange during growth phase.

The growth of nanoseeds involves placing the seeds into a growth solution. The growth solution requires a low concentration of a metal precursor, ligands that will readily exchange with preexisting seed ligands, and a weak or very low concentration of reducing agent. The reducing agent must not be strong enough to reduce metal precursor in the growth solution in the absence of seeds. Otherwise, the growth solution will form new nucleation sites instead of growing on preexisting ones (seeds).[31] Growth is the result of the competition between surface energy (which increases unfavorably with growth) and bulk energy (which decreases favorably with growth). The balance between the energetics of growth and dissolution is the reason for uniform growth only on preexisting seeds (and no new nucleation).[32] Growth occurs by the addition of metal atoms from the growth solution to the seeds, and ligand exchange between the growth ligands (which have a higher bonding affinity) and the seed ligands.[33]

Range and direction of growth can be controlled by nanoseed, concentration of metal precursor, ligand, and reaction conditions (heat, pressure, etc.).[34] Controlling stoichiometric conditions of growth solution controls ultimate size of particle. For example, a low concentration of metal seeds to metal precursor in the growth solution will produce larger particles. Capping agent has been shown to control direction of growth and thereby shape. Ligands can have varying affinities for binding across a particle. Differential binding within a particle can result in dissimilar growth across particle. This produces anisotropic particles with nonspherical shapes including prisms, cubes, and rods.[35] [36]

Light-mediated growth

Light-mediated syntheses have also been explored where light can promote formation of various silver nanoparticle morphologies.[10][37]

Silver mirror reaction

The silver mirror reaction involves the conversion of silver nitrate to Ag(NH3)OH. Ag(NH3)OH is subsequently reduced into colloidal silver using an aldehyde containing molecule such as a sugar. The silver mirror reaction is as follows:

- 2(Ag(NH3)2)+ + RCHO + 2OH− → RCOOH + 2Ag + 4NH3.[38]

The size and shape of the nanoparticles produced are difficult to control and often have wide distributions.[39] However, this method is often used to apply thin coatings of silver particles onto surfaces and further study into producing more uniformly sized nanoparticles is being done.[39]

Ion implantation

Ion implantation has been used to create silver nanoparticles embedded in glass, polyurethane, silicone, polyethylene, and poly(methyl methacrylate). Particles are embedded in the substrate by means of bombardment at high accelerating voltages. At a fixed current density of the ion beam up to a certain value, the size of the embedded silver nanoparticles has been found to be monodisperse within the population,[40] after which only an increase in the ion concentration is observed. A further increase in the ion beam dose has been found to reduce both the nanoparticle size and density in the target substrate, whereas an ion beam operating at a high accelerating voltage with a gradually increasing current density has been found to result in a gradual increase in the nanoparticle size. There are a few competing mechanisms which may result in the decrease in nanoparticle size; destruction of NPs upon collision, sputtering of the sample surface, particle fusion upon heating and dissociation.[40]

The formation of embedded nanoparticles is complex, and all of the controlling parameters and factors have not yet been investigated. Computer simulation is still difficult as it involves processes of diffusion and clustering, however it can be broken down into a few different sub-processes such as implantation, diffusion, and growth. Upon implantation, silver ions will reach different depths within the substrate which approaches a Gaussian distribution with the mean centered at X depth. High temperature conditions during the initial stages of implantation will increase the impurity diffusion in the substrate and as a result limit the impinging ion saturation, which is required for nanoparticle nucleation.[41] Both the implant temperature and ion beam current density are crucial to control in order to obtain a monodisperse nanoparticle size and depth distribution. A low current density may be used to counter the thermal agitation from the ion beam and a buildup of surface charge. After implantation on the surface, the beam currents may be raised as the surface conductivity will increase.[41] The rate at which impurities diffuse drops quickly after the formation of the nanoparticles, which act as a mobile ion trap. This suggests that the beginning of the implantation process is critical for control of the spacing and depth of the resulting nanoparticles, as well as control of the substrate temperature and ion beam density. The presence and nature of these particles can be analyzed using numerous spectroscopy and microscopy instruments.[41] Nanoparticles synthesized in the substrate exhibit surface plasmon resonances as evidenced by characteristic absorption bands; these features undergo spectral shifts depending on the nanoparticle size and surface asperities,[40] however the optical properties also strongly depend on the substrate material of the composite.

Biological synthesis

The biological synthesis of nanoparticles has provided a means for improved techniques compared to the traditional methods that call for the use of harmful reducing agents like sodium borohydride. Many of these methods could improve their environmental footprint by replacing these relatively strong reducing agents. The problems with the chemical production of silver nanoparticles is usually involves high cost and the longevity of the particles is short lived due to aggregation. The harshness of standard chemical methods has sparked the use of using biological organisms to reduce silver ions in solution into colloidal nanoparticles.[42][43]

In addition, precise control over shape and size is vital during nanoparticle synthesis since the NPs therapeutic properties are intimately dependent on such factors.[44] Hence, the primary focus of research in biogenic synthesis is in developing methods that consistently reproduce NPs with precise properties.[45][46]

Fungi and bacteria

Bacterial and fungal synthesis of nanoparticles is practical because bacteria and fungi are easy to handle and can be modified genetically with ease. This provides a means to develop biomolecules that can synthesize AgNPs of varying shapes and sizes in high yield, which is at the forefront of current challenges in nanoparticle synthesis. Fungal strains such as Verticillium and bacterial strains such as K. pneumoniae can be used in the synthesis of silver nanoparticles.[47] When the fungus/bacteria is added to solution, protein biomass is released into the solution.[47] Electron donating residues such as tryptophan and tyrosine reduce silver ions in solution contributed by silver nitrate.[47] These methods have been found to effectively create stable monodisperse nanoparticles without the use of harmful reducing agents.

A method has been found of reducing silver ions by the introduction of the fungus Fusarium oxysporum. The nanoparticles formed in this method have a size range between 5 and 15 nm and consist of silver hydrosol. The reduction of the silver nanoparticles is thought to come from an enzymatic process and silver nanoparticles produced are extremely stable due to interactions with proteins that are excreted by the fungi.

Bacterium found in silver mines, Pseudomonas stutzeri AG259, were able to construct silver particles in the shapes of triangles and hexagons. The size of these nanoparticles had a large range in size and some of them reached sizes larger than the usual nanoscale with a size of 200 nm. The silver nanoparticles were found in the organic matrix of the bacteria.[48]

Lactic acid producing bacteria have been used to produce silver nanoparticles. The bacteria Lactobacillus spp., Pediococcus pentosaceus, Enteroccus faeciumI, and Lactococcus garvieae have been found to be able to reduce silver ions into silver nanoparticles. The production of the nanoparticles takes place in the cell from the interactions between the silver ions and the organic compounds of the cell. It was found that the bacterium Lactobacillus fermentum created the smallest silver nanoparticles with an average size of 11.2 nm. It was also found that this bacterium produced the nanoparticles with the smallest size distribution and the nanoparticles were found mostly on the outside of the cells. It was also found that there was an increase in the pH increased the rate of which the nanoparticles were produced and the amount of particles produced.[49]

Plants

The reduction of silver ions into silver nanoparticles has also been achieved using geranium leaves. It has been found that adding geranium leaf extract to silver nitrate solutions causes their silver ions to be quickly reduced and that the nanoparticles produced are particularly stable. The silver nanoparticles produced in solution had a size range between 16 and 40 nm.[48]

In another study different plant leaf extracts were used to reduce silver ions. It was found that out of Camellia sinensis (green tea), pine, persimmon, ginko, magnolia, and platanus that the magnolia leaf extract was the best at creating silver nanoparticles. This method created particles with a disperse size range of 15 to 500 nm, but it was also found that the particle size could be controlled by varying the reaction temperature. The speed at which the ions were reduced by the magnolia leaf extract was comparable to those of using chemicals to reduce.[42][50]

The use of plants, microbes, and fungi in the production of silver nanoparticles is leading the way to more environmentally sound production of silver nanoparticles.[43]

A green method is available for synthesizing silver nanoparticles using Amaranthus gangeticus Linn leaf extract.[51]

Products and functionalization

Synthetic protocols for silver nanoparticle production can be modified to produce silver nanoparticles with non-spherical geometries and also to functionalize nanoparticles with different materials, such as silica. Creating silver nanoparticles of different shapes and surface coatings allows for greater control over their size-specific properties.

Anisotropic structures

Silver nanoparticles can be synthesized in a variety of non-spherical (anisotropic) shapes. Because silver, like other noble metals, exhibits a size and shape dependent optical effect known as localized surface plasmon resonance (LSPR) at the nanoscale, the ability to synthesize Ag nanoparticles in different shapes vastly increases the ability to tune their optical behavior. For example, the wavelength at which LSPR occurs for a nanoparticle of one morphology (e.g. a sphere) will be different if that sphere is changed into a different shape. This shape dependence allows a silver nanoparticle to experience optical enhancement at a range of different wavelengths, even by keeping the size relatively constant, just by changing its shape. The applications of this shape-exploited expansion of optical behavior range from developing more sensitive biosensors to increasing the longevity of textiles.[52][53]

Triangular nanoprisms

Triangular shaped nanoparticles are a canonical type of anisotropic morphology studied for both gold and silver.[54]

Though many different techniques for silver nanoprism synthesis exist, several methods employ a seed-mediated approach, which involves first synthesizing small (3-5 nm diameter) silver nanoparticles that offer a template for shape-directed growth into triangular nanostructures.[55]

The silver seeds are synthesized by mixing silver nitrate and sodium citrate in aqueous solution and then rapidly adding sodium borohydride. Additional silver nitrate is added to the seed solution at low temperature, and the prisms are grown by slowly reducing the excess silver nitrate using ascorbic acid.[6]

With the seed-mediated approach to silver nanoprism synthesis, selectivity of one shape over another can in part be controlled by the capping ligand. Using essentially the same procedure above but changing citrate to poly (vinyl pyrrolidone) (PVP) yields cube and rod-shaped nanostructures instead of triangular nanoprisms.[56]

In addition to the seed mediated technique, silver nanoprisms can also be synthesized using a photo-mediated approach, in which preexisting spherical silver nanoparticles are transformed into triangular nanoprisms simply by exposing the reaction mixture to high intensities of light.[57]

Nanocubes

Silver nanocubes can be synthesized using ethylene glycol as a reducing agent and PVP as a capping agent, in a polyol synthesis reaction (vide supra). A typical synthesis using these reagents involves adding fresh silver nitrate and PVP to a solution of ethylene glycol heated at 140 °C.[58]

This procedure can actually be modified to produce another anisotropic silver nanostructure, nanowires, by just allowing the silver nitrate solution to age before using it in the synthesis. By allowing the silver nitrate solution to age, the initial nanostructure formed during the synthesis is slightly different than that obtained with fresh silver nitrate, which influences the growth process, and therefore, the morphology of the final product.[58]

Coating with silica

In this method, polyvinylpyrrolidone (PVP) is dissolved in water by sonication and mixed with silver colloid particles.[1] Active stirring ensures the PVP has adsorbed to the nanoparticle surface.[1] Centrifuging separates the PVP coated nanoparticles which are then transferred to a solution of ethanol to be centrifuged further and placed in a solution of ammonia, ethanol and Si(OEt4) (TES).[1] Stirring for twelve hours results in the silica shell being formed consisting of a surrounding layer of silicon oxide with an ether linkage available to add functionality.[1] Varying the amount of TES allows for different thicknesses of shells formed.[1] This technique is popular due to the ability to add a variety of functionality to the exposed silica surface.

Use

Catalysis

Using silver nanoparticles for catalysis has been gaining attention in recent years. Although the most common applications are for medicinal or antibacterial purposes, silver nanoparticles have been demonstrated to show catalytic redox properties for dyes, benzene, carbon monoxide, and likely other compounds.

NOTE: This paragraph is a general description of nanoparticle properties for catalysis; it is not exclusive to silver nanoparticles. The size of a nanoparticle greatly determines the properties that it exhibits due to various quantum effects. Additionally, the chemical environment of the nanoparticle plays a large role on the catalytic properties. With this in mind, it is important to note that heterogeneous catalysis takes place by adsorption of the reactant species to the catalytic substrate. When polymers, complex ligands, or surfactants are used to prevent coalescence of the nanoparticles, the catalytic ability is frequently hindered due to reduced adsorption ability.[59] However, these compounds can also be used in such a way that the chemical environment enhances the catalytic ability.

Supported on silica spheres – reduction of dyes

Silver nanoparticles have been synthesized on a support of inert silica spheres.[59] The support plays virtually no role in the catalytic ability and serves as a method of preventing coalescence of the silver nanoparticles in colloidal solution. Thus, the silver nanoparticles were stabilized and it was possible to demonstrate the ability of them to serve as an electron relay for the reduction of dyes by sodium borohydride.[59] Without the silver nanoparticle catalyst, virtually no reaction occurs between sodium borohydride and the various dyes: methylene blue, eosin, and rose bengal.

Mesoporous aerogel – selective oxidation of benzene

Silver nanoparticles supported on aerogel are advantageous due to the higher number of active sites.[60] The highest selectivity for oxidation of benzene to phenol was observed at low weight percent of silver in the aerogel matrix (1% Ag). This better selectivity is believed to be a result of the higher monodispersity within the aerogel matrix of the 1% Ag sample. Each weight percent solution formed different sized particles with a different width of size range.[60]

Silver alloy – synergistic oxidation of carbon monoxide

Au-Ag alloy nanoparticles have been shown to have a synergistic effect on the oxidation of carbon monoxide (CO).[61] On its own, each pure-metal nanoparticle shows very poor catalytic activity for CO oxidation; together, the catalytic properties are greatly enhanced. It is proposed that the gold acts as a strong binding agent for the oxygen atom and the silver serves as a strong oxidizing catalyst, although the exact mechanism is still not completely understood. When synthesized in an Au/Ag ratio from 3:1 to 10:1, the alloyed nanoparticles showed complete conversion when 1% CO was fed in air at ambient temperature.[61] Interestingly, the size of the alloyed particles did not play a big role in the catalytic ability. It is well known that gold nanoparticles only show catalytic properties for CO when they are ~3 nm in size, but alloyed particles up to 30 nm demonstrated excellent catalytic activity – catalytic activity better than that of gold nanoparticles on active support such as TiO2, Fe2O3, etc.[61]

Light-enhanced

Plasmonic effects have been studied quite extensively. Until recently, there have not been studies investigating the oxidative catalytic enhancement of a nanostructure via excitation of its surface plasmon resonance. The defining feature for enhancing the oxidative catalytic ability has been identified as the ability to convert a beam of light into the form of energetic electrons that can be transferred to adsorbed molecules.[62] The implication of such a feature is that photochemical reactions can be driven by low-intensity continuous light can be coupled with thermal energy.

The coupling of low-intensity continuous light and thermal energy has been performed with silver nanocubes. The important feature of silver nanostructures that are enabling for photocatalysis is their nature to create resonant surface plasmons from light in the visible range.[62]

The addition of light enhancement enabled the particles to perform to the same degree as particles that were heated up to 40 K greater.[62] This is a profound finding when noting that a reduction in temperature of 25 K can increase the catalyst lifetime by nearly tenfold, when comparing the photothermal and thermal process.[62]

Biological research

Researchers have explored the use of silver nanoparticles as carriers for delivering various payloads such as small drug molecules or large biomolecules to specific targets. Once the AgNP has had sufficient time to reach its target, release of the payload could potentially be triggered by an internal or external stimulus. The targeting and accumulation of nanoparticles may provide high payload concentrations at specific target sites and could minimize side effects.[63]

Chemotherapy

The introduction of nanotechnology into medicine is expected to advance diagnostic cancer imaging and the standards for therapeutic drug design.[64] Nanotechnology may uncover insight about the structure, function and organizational level of the biosystem at the nanoscale.[65]

Silver nanoparticles can undergo coating techniques that offer a uniform functionalized surface to which substrates can be added. When the nanoparticle is coated, for example, in silica the surface exists as silicic acid. Substrates can thus be added through stable ether and ester linkages that are not degraded immediately by natural metabolic enzymes.[66][67] Recent chemotherapeutic applications have designed anti cancer drugs with a photo cleavable linker,[68] such as an ortho-nitrobenzyl bridge, attaching it to the substrate on the nanoparticle surface.[66] The low toxicity nanoparticle complex can remain viable under metabolic attack for the time necessary to be distributed throughout the bodies systems.[66][69] If a cancerous tumor is being targeted for treatment, ultraviolet light can be introduced over the tumor region.[66] The electromagnetic energy of the light causes the photo responsive linker to break between the drug and the nanoparticle substrate.[66] The drug is now cleaved and released in an unaltered active form to act on the cancerous tumor cells.[66] Advantages anticipated for this method is that the drug is transported without highly toxic compounds, the drug is released without harmful radiation or relying on a specific chemical reaction to occur and the drug can be selectively released at a target tissue.[66][67][69]

A second approach is to attach a chemotherapeutic drug directly to the functionalized surface of the silver nanoparticle combined with a nucelophilic species to undergo a displacement reaction. For example, once the nanoparticle drug complex enters or is in the vicinity of the target tissue or cells, a glutathione monoester can be administered to the site.[70][71] The nucleophilic ester oxygen will attach to the functionalized surface of the nanoparticle through a new ester linkage while the drug is released to its surroundings.[70][71] The drug is now active and can exert its biological function on the cells immediate to its surroundings limiting non-desirable interactions with other tissues.[70][71]

Multiple drug resistance

A major cause for the ineffectiveness of current chemotherapy treatments is multiple drug resistance which can arise from several mechanisms.[72]

Nanoparticles can provide a means to overcome MDR. In general, when using a targeting agent to deliver nanocarriers to cancer cells, it is imperative that the agent binds with high selectivity to molecules that are uniquely expressed on the cell surface. Hence NPs can be designed with proteins that specifically detect drug resistant cells with overexpressed transporter proteins on their surface.[73] A pitfall of the commonly used nano-drug delivery systems is that free drugs that are released from the nanocarriers into the cytosol get exposed to the MDR transporters once again, and are exported. To solve this, 8 nm nano crystalline silver particles were modified by the addition of trans-activating transcriptional activator (TAT), derived from the HIV-1 virus, which acts as a cell penetrating peptide (CPP).[74] Generally, AgNP effectiveness is limited due to the lack of efficient cellular uptake; however, CPP-modification has become one of the most efficient methods for improving intracellular delivery of nanoparticles. Once ingested, the export of the AgNP is prevented based on a size exclusion. The concept is simple: the nanoparticles are too large to be effluxed by the MDR transporters, because the efflux function is strictly subjected to the size of its substrates, which is generally limited to a range of 300-2000 Da. Thereby the nanoparticulates remain insusceptible to the efflux, providing a means to accumulate in high concentrations.

Antimicrobial

Introduction of silver into bacterial cells induces a high degree of structural and morphological changes, which can lead to cell death. As the silver nano particles come in contact with the bacteria, they adhere to the cell wall and cell membrane.[75] Once bound, some of the silver passes through to the inside, and interacts with phosphate-containing compounds like DNA and RNA, while another portion adheres to the sulphur-containing proteins on the membrane.[75] The silver-sulphur interactions at the membrane cause the cell wall to undergo structural changes, like the formation of pits and pores.[76] Through these pores, cellular components are released into the extracellular fluid, simply due to the osmotic difference. Within the cell, the integration of silver creates a low molecular weight region where the DNA then condenses.[76] Having DNA in a condensed state inhibits the cell’s replication proteins contact with the DNA. Thus the introduction of silver nanoparticles inhibits replication and is sufficient to cause the death of the cell. Further increasing their effect, when silver comes in contact with fluids, it tends to ionize which increases the nanoparticles bactericidal activity.[76] This has been correlated to the suppression of enzymes and inhibited expression of proteins that relate to the cell’s ability to produce ATP.[77]

Although it varies for every type of cell proposed, as their cell membrane composition varies greatly, It has been seen that in general, silver nano particles with an average size of 10 nm or less show electronic effects that greatly increase their bactericidal activity.[78] This could also be partly due to the fact that as particle size decreases, reactivity increases due to the surface area to volume ratio increasing.

It has been noted that the introduction of silver nano particles has shown to have synergistic activity with common antibiotics already used today, such as; penicillin G, ampicillin, erythromycin, clindamycin, and vancomycin against E. coli and S. aureus.[79] In medical equipment, it has been shown that silver nano particles drastically lower the bacterial count on devices used. However, the problem arises when the procedure is over and a new one must be done. In the process of washing the instruments a large portion of the silver nano particles become less effective due to the loss of silver ions. They are more commonly used in skin grafts for burn victims as the silver nano particles embedded with the graft provide better antimicrobial activity and result in significantly less scarring of the victim. They also show promising application as water treatment method to form clean potable water.[80]

Silver nanoparticles can prevent bacteria from growing on or adhering to the surface. This can be especially useful in surgical settings where all surfaces in contact with the patient must be sterile. Interestingly, silver nanoparticles can be incorporated on many types of surfaces including metals, plastic, and glass.[81] In medical equipment, it has been shown that silver nano particles lower the bacterial count on devices used compared to old techniques. However, the problem arises when the procedure is over and a new one must be done. In the process of washing the instruments a large portion of the silver nano particles become less effective due to the loss of silver ions. They are more commonly used in skin grafts for burn victims as the silver nano particles embedded with the graft provide better antimicrobial activity and result in significantly less scarring of the victim.These new applications are direct decedents of older practices that used silver nitrate to treat conditions such as skin ulcers. Now, silver nanoparticles are used in bandages and patches to help heal certain burns and wounds.[82]

They also show promising application as water treatment method to form clean potable water.[80] This doesn’t sound like much, but water contains numerous diseases and some parts of the world do not have the luxury of clean water, or any at all. It wasn’t new to use silver for removing microbes, but this experiment used the carbonate in water to make microbes even more vulnerable to silver.[83] First the scientists of the experiment use the nanopaticles to remove certain pesticides from the water, ones that prove fatal to people if ingested. Several other tests have shown that the silver nanoparticles were capable of removing certain ions in water as well, like iron, lead, and arsenic. But that is not the only reason why the silver nanoparticles are so appealing, they do not require any external force (no electricity of hydrolics) for the reaction to occur.[84]

Consumer Goods

Household appliances

There are instances in which silver nanoparticles and colloidal silver are used in consumer goods. Samsung and LG are two major tech companies planning to use antibacterial properties of silver nanoparticles in a multitude of appliances such as air conditioners, washing machines, and refrigerators.[85] For example, both companies claim that the use of silver nanoparticles in washing machines would help to sterilize clothes and water during the washing and rinsing functions, and allow clothes to be cleaned without the need for hot water.[85][86] The nanoparticles in these appliances are synthesized using electrolysis. Through electrolysis, silver is extracted from metal plates and then turned into silver nanoparticles by a reduction agent.[87] This method avoids the drying, cleaning and re-dispersion processes, which are generally required with alternative colloidal synthesis methods.[87] Importantly, the electrolysis strategy also decreases the production cost of Ag nanoparticles, making these washing machines more affordable to manufacture.[88] Samsung has described the system:

[A] grapefruit-sized device alongside the [washer] tub uses electrical currents to nanoshave two silver plates the size of large chewing gum sticks. Resulting in positively charged silver atoms-silver ions (Ag+)-are injected into the tub during the wash cycle.[88]

It is important to note that Samsung’s description of the Ag nanoparticle generating process seems to contradict its advertisement of silver nanoparticles. Instead, the statement indicates that laundry cycles.[87][88] When clothes are run through the cycle, the intended mode of action is that bacteria contained in the water are sterilized as they interact with the silver present in the washing tub.[86][88] As a result, these washing machines can provide antibacterial and sterilization benefits on top of conventional washing methods. Samsung has commented on the lifetime of these silver-containing washing machines. The electrolysis of silver generates over 400 billion silver ions during each wash cycle. Given the size of the silver source (two “gum-sized” plate of Ag), Samsung estimates that these plates can last up to 3000 wash cycles.[88]

These plans by Samsung and LG are not overlooked by regulatory agencies. Agencies investigating LG's nanoparticle use include but are not limited to: the U.S. FDA, U.S. EPA, SIAA of Japan, and Korea's Testing and Research Institute for Chemical Industry and FITI Testing & Research Institute.[86] These various agencies plan to regulate silver nanoparticles in appliances.[86] These washing machines are some of the first cases in which the EPA has sought to regulate nanoparticles in consumer goods. LG and Samsung state that the silver gets washed away in the sewer and regulatory agencies worry over what that means for wastewater treatment streams.[88] Currently, the EPA classifies silver nanoparticles as pesticides due to their use as antimicrobial agents in wastewater purification.[85] The washing machines being developed by LG and Samsung do contain a pesticide and have to be registered and tested for safety under the law, particularly the US Federal insecticide, fungicide and rodenticide act.[85] The difficulty, however behind regulating nanotechnology in this manner is that there is no distinct way to measure toxicity. Tim Harper, CEO of nanotechnology consultants Cientifica, explained, "we don’t really have the science to prove anything one way or another".[85] The example of these washing machines demonstrates that while nanotechnology using silver nanoparticles in commercial appliances is showing promise, ways to measure toxicity and health hazards to humans, bacteria, or the environment will continue to be hurdle for nanoparticle technology implementation.

Safety

Although silver nanoparticles are widely used in a variety of commercial products, there has only recently been a major effort to study their effects on human health. There have been several studies that describe the in vitro toxicity of silver nanoparticles to a variety of different organs, including the lung, liver, skin, brain, and reproductive organs.[89] The mechanism of the toxicity of silver nanoparticles to human cells appears to be derived from oxidative stress and inflammation that is caused by the generation of reactive oxygen species (ROS) stimulated by either the Ag NPs, Ag ions, or both.[90][91][92][93][94] For example, Park et al. showed that exposure of a mouse peritoneal macrophage cell line (RAW267.7) to silver nanoparticles decreased the cell viability in a concentration- and time-dependent manner.[93] They further showed that the intracellular reduced glutathionine (GSH), which is a ROS scavenger, decreased to 81.4% of the control group of silver nanoparticles at 1.6 ppm.[93]

Modes of toxicity

Since silver nanoparticles undergo dissolution releasing silver ions,[95] which is well-documented to have toxic effects,[94][95][96] there have been several studies that have been conducted to determine whether the toxicity of silver nanoparticles is derived from the release of silver ions or from the nanoparticle itself. Several studies suggest that the toxicity of silver nanoparticles is attributed to their release of silver ions in cells as both silver nanoparticles and silver ions have been reported to have similar cytotoxicity.[92][93][97][98] For example, In some cases it is reported that silver nanoparticles facilitate the release of toxic free silver ions in cells via a "Trojan-horse type mechanism," where the particle enters cells and is then ionized within the cell.[93] However, there have been reports that suggest that a combination of silver nanoparticles and ions is responsible for the toxic effect of silver nanoparticles. Navarro et al. using cysteine ligands as a tool to measure the concentration of free silver in solution, determined that although initially silver ions were 18 times more likely to inhibit the photosynthesis of an algae, Chlamydomanas reinhardtii, but after 2 hours of incubation it was revealed that the algae containing silver nanoparticles were more toxic than just silver ions alone.[99] Furthermore, there are studies that suggest that silver nanoparticles induce toxicity independent of free silver ions.[94][100][101] For example, Asharani et al. compared phenotypic defects observed in zebrafish treated with silver nanoparticles and silver ions and determined that the phenotypic defects observed with silver nanoparticle treatment was not observed with silver ion-treated embryos, suggesting that the toxicity of silver nanoparticles are independent of silver ions.[101]

Protein channels and nuclear membrane pores can often be in the size range of 9 nm to 10 nm in diameter.[94] Small silver nanoparticles constructed of this size have the ability to not only pass through the membrane to interact with internal structures but also to be become lodged within the membrane.[94] Silver nanoparticle depositions in the membrane can impact regulation of solutes, exchange of proteins and cell recognition.[94] Exposure to silver nanoparticles has been associated with "inflammatory, oxidative, genotoxic, and cytotoxic consequences"; the silver particulates primarily accumulate in the liver.[102] but have also been shown to be toxic in other organs including the brain.[103] Nano-silver applied to tissue-cultured human cells leads to the formation of free radicals, raising concerns of potential health risks.[104]

- Allergic reaction: There have been several studies conducted that show a precedence for allerginicity of silver nanoparticles.[105][106]

- Argyria and staining: Ingested silver or silver compounds, including colloidal silver, can cause a condition called argyria, a discoloration of the skin and organs.In 2006, there was a case study of a 17-year-old man, who sustained burns to 30% of his body, and experienced a temporary bluish-grey hue after several days of treatment with Acticoat, a brand of wound dressing containing silver nanoparticles.[107] Argyria is the deposition of silver in deep tissues, a condition that cannot happen on a temporary basis, raising the question of whether the cause of the man’s discoloration was argyria or even a result of the silver treatment.[108] Silver dressings are known to cause a “transient discoloration” that dissipates in 2–14 days, but not a permanent discoloration.

- Silzone heart valve: St. Jude Medical released a mechanical heart valve with a silver coated sewing cuff (coated using ion beam-assisted deposition) in 1997.[109] The valve was designed to reduce the instances of endocarditis. The valve was approved for sale in Canada, Europe, the United States, and most other markets around the world. In a post-commercialization study, researchers showed that the valve prevented tissue ingrowth, created paravalvular leakage, valve loosening, and in the worst cases explantation. After 3 years on the market and 36,000 implants, St. Jude discontinued and voluntarily recalled the valve.

References

- 1 2 3 4 5 6 7 Graf, Christina; Vossen, Dirk L.J.; Imhof, Arnout; van Blaaderen, Alfons (July 11, 2003). "A General Method To Coat Colloidal Particles with Silica". Langmuir. 19 (17): 6693–6700. doi:10.1021/la0347859.

- ↑ , Polte, Jörg. "Fundamental Growth Principles of Colloidal Metal Nanoparticles – a New Perspective."

- ↑ , Rama, Siva, Krishna Perala, and Sanjeev Kumar. "On the Mechanism of Metal Nanoparticle Synthesis in the Brust–Schiffrin Method.”

- 1 2 ,Hao, Chenhui, Dingsheng Wang, Wen Zheng, and Qing Peng. "Growth and Assembly of Monodisperse Ag Nanoparticles by Exchanging the Organic Capping Ligands."

- ↑ , Johnston, Kathryn A., Ashley M. Smith, Lauren E. Marbella, and Jill E. Millstone. "Impact of As-Synthesized Ligands and Low-Oxygen Conditions on Silver Nanoparticle Surface Functionalization."

- 1 2 Dong, X.; Ji, X.; Jing, J.; Li, M.; Li, J.; Yang, W. (2010). "Synthesis Of Triangular Silver Nanoprisms by Stepwise Reduction of Sodium Borohydride and Trisodium Citrate". J. Phys. Chem. C. 114 (5): 2070–2074. doi:10.1021/jp909964k.

- ↑ Shan, Z.; Wu, J.; Xu, F.; Huang, F.-Q.; Ding, H. (2008). "Highly Effective Silver/Semiconductor Photocatalytic Composites Prepared By a Silver Mirror Reaction". J. Phys. Chem. C. 112 (39): 15423–15428. doi:10.1021/jp804482k.

- 1 2 Wiley, B.; Sun, Y.; Xia, Y. Synthesis Of Silver Nanostructures with Controlled Shapes and Properties. Accounts of Chemical Research Acc. Chem. Res. 2007, 40, 1067–1076.

- ↑ Pietrobon, B.; Mceachran, M.; Kitaev, V. Synthesis Of Size-Controlled Faceted Pentagonal Silver Nanorods with Tunable Plasmonic Properties and Self-Assembly of These Nanorods. ACS Nano. 2009, 3, 21–26.

- 1 2 Tanimoto, H.; Ohmura, S.; Maeda, Y. Size-Selective Formation Of Hexagonal Silver Nanoprisms in Silver Citrate Solution by Monochromatic-Visible-Light Irradiation. J. Phys. Chem. C.2012, 116, 15819–15825.

- 1 2 Rycenga, M.; Cobley, C. M.; Zeng, J.; Li, W.; Moran, C. H.; Zhang, Q.; Qin, D.; Xia, Y. (2011). "Controlling The Synthesis and Assembly of Silver Nanostructures for Plasmonic Applications". Chemical Reviews. 111 (6): 3669–3712. doi:10.1021/cr100275d.

- ↑ "Green sonochemical synthesis of silver nanoparticles at varying concentrations of κ-carrageenan" (PDF). springer.com. Retrieved 2016-02-15.

- ↑ "Green Sonochemical Route to Silver Nanoparticles". hielscher.com. Retrieved 2016-02-15.

- 1 2 Iravani, S., Korbekandi, H., Mirmohammadi, S. V., & Zolfaghari, B. (2014). Synthesis of silver nanoparticles: chemical, physical and biological methods. Research in Pharmaceutical Sciences, 9(6), 385–406.

- ↑ El-Rafie, M. H., Ahmed, H. B., & Zahran, M. K. (2014). Facile Precursor for Synthesis of Silver Nanoparticles Using Alkali Treated Maize Starch. International Scholarly Research Notices, 2014, 1-12. doi:10.1155/2014/702396

- ↑ Darroudi, M., Ahmad, M. M., Abdullah, A. H., Ibrahim, N. A., & Shameli, K. (2011). Green synthesis and characterization of gelatin-based and sugar-reduced silver nanoparticles. International Journal of Nanomedicine, 569. doi:10.2147/ijn.s16867

- 1 2 , Nowack, Bernd, Harald F. Krug, and Murray Height. "120 Years of Nanosilver History: Implications for Policy Makers."

- 1 2 3 , Wojtysiak, Sebastian, and Andrzej Kudelski. "Influence of Oxygen on the Process of Formation of Silver Nanoparticles during Citrate/borohydride Synthesis of Silver Sols."

- 1 2 3 K. C. Song, S. M. Lee, T. S. Park, and B. S. Lee, “Preparation of colloidal silver nanoparticles by chemical reduction method,” Korean J. Chem. Eng, vol. 26, no. 1, pp. 153–155, 2009.

- ↑ L. Bahrig, S. G. Hickey, and A. Eychmüller, “Mesocrystalline materials and the involvement of oriented attachment – a review,” CrystEngComm, vol. 16, no. 40, pp. 9408–9424, 2014.

- 1 2 Y. Sun and Y. Xia, “Triangular nanoplates of silver: Synthesis, characterization, and use as sacrificial templates for generating triangular nanorings of gold,” Adv. Mater., vol. 15, no. 9, pp. 695–699, 2003.

- 1 2 A. B. Smetana, K. J. Klabunde, and C. M. Sorensen, “Synthesis of spherical silver nanoparticles by digestive ripening, stabilization with various agents, and their 3-D and 2-D superlattice formation,” J. Colloid Interface Sci., vol. 284, no. 2, pp. 521–526, 2005.

- ↑ N. R. Jana, L. Gearheart, and C. J. Murphy, “Seeding growth for size control of 5-40 nm diameter gold nanoparticles,” Langmuir, vol. 17, no. 22, pp. 6782–6786, 2001.

- ↑ Polyol Synthesis of Silver Nanoparticles: Use of Chloride and Oxygen to Promote the Formation of Single-Crystal, Truncated Cubes and Tetrahedrons Benjamin Wiley,†, Thurston Herricks,‡, Yugang Sun,§ and, and Younan Xia*,§ Nano Letters 2004 4 (9), 1733-1739

- ↑ Low-Temperature Polyol Synthesis of AuCuSn2 and AuNiSn2: Using Solution Chemistry to Access Ternary Intermetallic Compounds as Nanocrystals Brian M. Leonard,Nattamai S. P. Bhuvanesh, and, and Raymond E. Schaak* Journal of the American Chemical Society 2005 127 (20), 7326-7327

- ↑ Polyol Synthesis of Silver Nanowires: An Extensive Parametric Study Sahin Coskun, Burcu Aksoy, and Husnu Emrah Unalan Crystal Growth & Design 2011 11 (11), 4963-4969

- ↑ Xia, Y.; Xiong, Y.; Lim, B.; Skrabalak, S. E. Shape-Controlled Synthesis Of Metal Nanocrystals: Simple Chemistry Meets Complex Physics?" Angew. Chem. Int. Ed. 2008; 48, 60–103.

- ↑ Shape‐Controlled Synthesis of Metal Nanocrystals: Simple Chemistry Meets Complex Physics? Xia, Younan, et al. Angewandte Chemie International Edition 48.1 (2009): 60-103.

- ↑ Theory, Production and Mechanism of Formation of Monodispersed Hydrosols, Victor K. LaMer and Robert H. Dinegar, Journal of the American Chemical Society 1950 72 (11), 4847-4854

- ↑ Control of Gold Nanoparticle Aggregates by Manipulation of Interparticle Interaction, Taehoon Kim, Kangtaek Lee, Myoung-seon Gong, and Sang-Woo Joo; Langmuir 2005 21 (21), 9524-9528

- ↑ Precise seed-mediated growth and size-controlled synthesis of palladium nanoparticles using a green chemistry approach. Liu, Juncheng, et al. Langmuir 25.12 (2009): 7116-7128.

- ↑ Energetic clues to pathways to biomineralization: Precursors, clusters, and nanoparticles, PNAS 2004 101 (33) 12096-12101; published ahead of print August 5, 2004

- ↑ Kinetically Controlled Seeded Growth Synthesis of Citrate-Stabilized Gold Nanoparticles of up to 200 nm: Size Focusing versus Ostwald Ripening. Neus G. Bastús, Joan Comenge, and Víctor Puntes; Langmuir 2011 27 (17), 11098-11105

- ↑ Seed-mediated successive growth of gold particles accomplished by UV irradiation: a photochemical approach for size-controlled synthesis. Mallick, Kaushik, Z. L. Wang, and Tarasankar Pal. Journal of Photochemistry and Photobiology A: Chemistry 140.1 (2001): 75-80.

- ↑ Controlling the aspect ratio of inorganic nanorods and nanowires. Murphy, Catherine J., and Nikhil R. Jana. Advanced Materials 14.1 (2002): 80.

- ↑ Seed-Mediated Synthesis of Ag Nanocubes with Controllable Edge Lengths in the Range of 30−200 nm and Comparison of Their Optical Properties. Qiang Zhang, Weiyang Li, Christine Moran, Jie Zeng, Jingyi Chen, Long-Ping Wen, and Younan Xia, Journal of the American Chemical Society 2010 132 (32), 11372-11378

- ↑ Wu, X.; Redmond, P. L.; Liu, H.; Chen, Y.; Steigerwald, M.; Brus, L. Photovoltage Mechanism For Room Light Conversion of Citrate Stabilized Silver Nanocrystal Seeds to Large Nanoprisms" J. Am. Chem. Soc 2009; 130, 9500–9506.

- ↑ Facile synthesis of silver nanoparticles with high concentration via a CTAB-induced silver mirror reaction. (n.d.).

- 1 2 Controlling the Synthesis and Assembly of Silver Nanostructures for Plasmonic Applications. (n.d.).

- 1 2 3 V. N. Popok, V. B. Odzhaev, A. L. Stepanov. "Synthesis of Silver Nanoparticles by the Ion Implantation Method and Investigation of their Optical Properties." Journal of Applied Spectroscopy. 2005. Volume 72. Number 2. Page 229.

- 1 2 3 Stepanov, A. "Synthesis Of Silver Nanoparticles In Dielectric Matrix By Ion Implantation: A Review." Review of Advanced Material Science. 2010. Volume 26. Pages 1-29.

- 1 2 Song, Jae Yong; Kim, Beom Soo (2008-04-26). "Rapid biological synthesis of silver nanoparticles using plant leaf extracts". Bioprocess and Biosystems Engineering. 32 (1): 79–84. doi:10.1007/s00449-008-0224-6. ISSN 1615-7591.

- 1 2 Shankar, S. Shiv; Ahmad, Absar; Sastry, Murali (2003-01-01). "Geranium Leaf Assisted Biosynthesis of Silver Nanoparticles". Biotechnology Progress. 19 (6): 1627–1631. doi:10.1021/bp034070w. ISSN 1520-6033. PMID 14656132.

- ↑ Bhattacharya, Resham; Mukherjee, Priyabrata (March 12, 2008). "Biological properties of "naked" metal nanoparticles". Advanced Drug Delivery Reviews. 60 (11): 1289–306. doi:10.1016/j.addr.2008.03.013.

- ↑ Shankar, S Shiv; Rai, Akhilesh; Ahmad, Absar; Sastry, Murali (July 15, 2007). "Rapid synthesis of Au, Ag, and bimetallic Au core–Ag shell nanoparticles using Neem (Azadirachta indica) leaf broth". Journal of Colloid and Interface Science. 275 (2): 496–502. doi:10.1016/j.jcis.2004.03.003.

- ↑ Li, Guangquan; He, Dan; Qian, Yongqing; Guan, Buyuan; Gao, Song; Cui, Yan; Yokoyama, Koji; Wang, Li (December 29, 2011). "Biological synthesis of silver nanoparticles using the fungus Aspergillus flavus". Int. J. Mol. Sci. 13 (1): 466–476. doi:10.3390/ijms13010466. PMC 3269698

. PMID 22312264.

. PMID 22312264. - 1 2 3 Ahmad, Absar; Mukherjee, Priyabrata; Senapati, Satyajoyti; Mandal, Deendayal; Khan, M.Islam; Kumar, Rajiv; Sastry, Murali (January 16, 2003). "Extracellular biosynthesis of silver nanoparticles using the fungus Fusarium oxysporum". Colloids and Surfaces B: Biointerfaces. 28 (4): 313–318. doi:10.1016/s0927-7765(02)00174-1.

- 1 2 Klaus, Tanja; Joerger, Ralph; Olsson, Eva; Granqvist, Claes-Göran (1999-11-23). "Silver-based crystalline nanoparticles, microbially fabricated". Proceedings of the National Academy of Sciences. 96 (24): 13611–13614. Bibcode:1999PNAS...9613611K. doi:10.1073/pnas.96.24.13611. ISSN 0027-8424. PMID 10570120.

- ↑ Sintubin, Liesje; Windt, Wim De; Dick, Jan; Mast, Jan; Ha, David van der; Verstraete, Willy; Boon, Nico (2009-06-02). "Lactic acid bacteria as reducing and capping agent for the fast and efficient production of silver nanoparticles". Applied Microbiology and Biotechnology. 84 (4): 741–749. doi:10.1007/s00253-009-2032-6. ISSN 0175-7598.

- ↑ Babu Sainath, Michele Claville and Kesete Ghebreyessus (2015). "Rapid synthesis of highly stable silver nanoparticles and its application for colourimetric sensing of cysteine". Journal of Experimental Nanoscience. 10 (16): 1242–1255. doi:10.1080/17458080.2014.994680.

- ↑ Kolya, Haradhan; Maiti, Parthapratim; Pandey, Akhil; Tripathy, Tridib (2015). "Green synthesis of silver nanoparticles with antimicrobial and azo dye (Congo red) degradation properties using Amaranthus gangeticus Linn leaf extract". Journal of Analytical Science and Technology. 6 (1). doi:10.1186/s40543-015-0074-1. ISSN 2093-3371.

- ↑ Abel, B.; Coskun, S.; Mohammed, M.; Williams, R.; Unalan, H. E.; Aslan, K. "Metal-Enhanced Fluorescence from Silver Nanowires with High Aspect Ratio on Glass Slides for Biosensing Applications" J. Phys. Chem. C. 2015, 119, 675-684. doi:10.1021/jp509040f

- ↑ Tang, B.; Zhang, M.; Hou, X.; Li, J.; Sun, L.; Wang, X. "Colored and Functional Silver Nanoparticle−Wool Fiber Composites" Ind. Eng. Chem. Res. 2012, 51, 12807-12813. doi:10.1021/am101224v

- ↑ Millstone J. E.; Park S.; Shuford K. L.; Qin L.; Schatz G. C.; Mirkin C. A. (2005). "Observation of a Quadrupole Plasmon Mode for a Colloidal Solution of Gold Nanoprisms". J. Am. Chem. Soc. 127: 5312–5313. doi:10.1021/ja043245a.

- ↑ Dong, X.; Ji, X.; Jing, J.; Li, M.; Li, J.; Yang, W. J. Phys. Chem. C. 2010, 114, 2070-2074.

- ↑ Zeng J.; Zheng Y.; Rycenga M.; Tao J.; Li Z.; Zhang Q.; Zhu Y. (2010). "Controlling the Shapes of Silver Nanocrystals with Different Capping Agents". J. Am. Chem. Soc. 132: 8552–8553. doi:10.1021/ja103655f.

- ↑ Xue C.; Métraux G. S.; Millstone J. E.; Mirkin C. A. (2008). "Mechanistic study of photomediated triangular silver nanoprism growth". J. Am. Chem. Soc. 130: 8337–8344. doi:10.1021/ja8005258.

- 1 2 Chang, S.; Chen, K.; Hua, Q.; Ma, Y.; Huang. W. "Evidence for the growth mechanisms of silver nanocubes and nanowires" J. Phys. Chem. C. 2011, 115, 7979-7986. doi:10.1021/jp2010088

- 1 2 3 Jiang, Zhong-Jie; Liu, Chun-Yan; Sun, Lu-Wei (2005-02-01). "Catalytic Properties of Silver Nanoparticles Supported on Silica Spheres". The Journal of Physical Chemistry B. 109 (5): 1730–1735. doi:10.1021/jp046032g. ISSN 1520-6106.

- 1 2 Ameen, K. Balkis; Rajasekar, K.; Rajasekharan, T. (2007-08-15). "Silver Nanoparticles in Mesoporous Aerogel Exhibiting Selective Catalytic Oxidation of Benzene in CO2 Free Air". Catalysis Letters. 119 (3-4): 289–295. doi:10.1007/s10562-007-9233-3. ISSN 1011-372X.

- 1 2 3 Liu, Jun-Hong; Wang, Ai-Qin; Chi, Yu-Shan; Lin, Hong-Ping; Mou, Chung-Yuan (2005-01-01). "Synergistic Effect in an Au−Ag Alloy Nanocatalyst: CO Oxidation". The Journal of Physical Chemistry B. 109 (1): 40–43. doi:10.1021/jp044938g. ISSN 1520-6106.

- 1 2 3 4 Christopher, Phillip; Xin, Hongliang; Linic, Suljo (2011-06-01). "Visible-light-enhanced catalytic oxidation reactions on plasmonic silver nanostructures". Nature Chemistry. 3 (6): 467–472. Bibcode:2011NatCh...3..467C. doi:10.1038/nchem.1032. ISSN 1755-4330.

- ↑ Pickup, J.C.; Zhi, Z.L.; Khan, F.; Saxl, T.; Birch, D.J. "Birch nanomedicine and its potential in diabetes research and practice". Diabetes Metab Res Rev. 24 (8): 604–610. doi:10.1002/dmrr.893. PMID 18802934.

- ↑ Peer, Dan; Karp, Jeffrey M.; Hong, Seungpyo; Farokhzad, Omid C.; Margalit, Rimona; Langer, Robert. "Nanocarriers as an emerging platform for cancer therapy". Nature Nanotechnology. 2: 751–760. Bibcode:2007NatNa...2..751P. doi:10.1038/nnano.2007.387.

- ↑ Kairemo, Kalevi; Erba, Paola; Bergström, Kim; Pauwels, Ernest K.J. (January 2010). "Nanoparticles in cancer". Current Radiopharmaceuticals. 1 (1): 30–36. doi:10.2174/1874471010801010030.

- 1 2 3 4 5 6 7 Agasti, Sarit S.; Chompoosor, Apiwat; You, Chang-Cheng; Ghosh, Partha; Kim, Chae Kyu; Rotello, Vincent M. (April 7, 2009). "Photoregulated release of caged anticancer drugs from gold nanoparticles". J. Am. Chem. Soc. 131 (16): 5728–5729. doi:10.1021/ja900591t.

- 1 2 Mukherjee, Sudip; Chowdhury, Debabrata; Kotcherlakota, Rajesh; Parta, Sujata; B, Vinothkumar; Bhadra, Manika Pal; Sreedhar, Bojja; Patra, Chitta Ranjan (January 29, 2014). "Potential theranostic application of biosynthesized silver nanoparticles". Theranostics. 4 (3): 316–335. doi:10.7150/thno.7819.

- ↑ Kim, Moon Suk; Diamond, Scott L. (August 2006). "Photocleavage of o-nitrobenzyl ether derivatives for rapid biomedical release applications". Bioorganic & Medicinal Chemistry Letters. 16 (15): 4007–4010. doi:10.1016/j.bmcl.2006.05.013.

- 1 2 "Ions, not particles, make silver toxic to bacteria". Phys Org. Retrieved February 28, 2015.

- 1 2 3 Hong, Rui; Han, Gang; Fernández, Joseph M.; Kim, Byoung-jin; Forbes, Neil S.; Rotello, Vincent M. (2006). "Glutathione mediated delivery and release using monolayer protected nanoparticle carriers". J. Am. Chem. Soc. 128 (4): 1078–1079. doi:10.1021/ja056726i.

- 1 2 3 Ock, Kwangsu; Jeon, Won II; Ganbold, Erdene Ochir; Kim, Mira; Park, Jihno; Seo, Ji Hyde; Cho, Keunchang; Jooo, Sang-Woo; Lee, So Yeong (January 26, 2012). "Real time monitoring of glutathione triggered thiopurine anticancer drug release in live cells investigated by surface enhanced raman scattering". Analytical Chemistry. 84 (5): 2172–2178. doi:10.1021/ac2024188.

- ↑ Fodale, V.; Pierobon, M.; Liotta, L.; Petricoin, E. "Mechanism of cell adaptation: when and how do cancer cells develop chemoresistance?". Cancer J. 17 (2): 89–95. doi:10.1097/PPO.0b013e318212dd3d.

- ↑ Ghosh, Partha; Han, Gang; De, Mrinmoy; Kim, Chae Kyu; Rotello, Vincent M. (August 17, 2008). "Gold nanoparticles in delivery applications". Advance Drug Delivery Reviews. 60 (11): 1307–1315. doi:10.1016/j.addr.2008.03.016.

- ↑ Liu, J.; Zhao, Y.; Guo, Q.; Wang, Z.; Wang, H.; Yang, Y.; Huang, Y. (September 2012). "TAT-modified nanosilver for combating multidrug-resistant cancer". Biomaterials. 33 (26): 6155–6161. doi:10.1016/j.biomaterials.2012.05.035.

- 1 2 Klasen, H.J. (March 2000). "A historical review of the use of silver in the treatment of burns". Burns. 26 (2): 117–130. doi:10.1016/s0305-4179(99)00108-4.

- 1 2 3 Feng, Q.L.; Wu, J.; Chen, G.Q.; Cui, F.Z.; Kim, T.N.; Kim, J.O. (December 15, 2000). "A mechanistic study of the antibacterial effect of silver ions on Escherichia coli and Staphylococcus aureus". J. Biomed. Mater. Res. 52 (4): 662–668. doi:10.1002/1097-4636(20001215)52:4<662::aid-jbm10>3.0.co;2-3.

- ↑ Yamanaka, Mikihiro; Hara, Keita; Kudo, Jun (November 2005). "Bactericidal Actions of a Silver Ion Solution on Escherichia coli, Studied by Energy-Filtering Transmission Electron Microscopy and Proteomic Analysis". Applied and Environmental Microbiology. 71 (11): 7589–7593. doi:10.1128/AEM.71.11.7589-7593.2005. PMC 1287701

. PMID 16269810.

. PMID 16269810. - ↑ Pal, Sukdeb; Tak, Yu Kyung; Song, Joon Myong (January 16, 2007). "Does the antibacterial activity of silver nanoparticles depend on the shape of the nanoparticle? A study of the gram-negative bacterium Escherichia coli". Applied and Environmental Microbiology. 73 (6): 1712–1720. doi:10.1128/AEM.02218-06.

- ↑ Shahverdi, Ahmad R.; Fakhimi, Ali; Shahverdi, Hamid Q.; Minaian, Sara (May 10, 2007). "Synthesis and effect of silver nanoparticles on the antibacterial activity of different antibiotics against Staphylococcus aureus and Escherichia coli". Nanomedicine. 3 (2): 168–171. doi:10.1016/j.nano.2007.02.001. PMID 17468052.

- 1 2 Jain, P.; Pradeep, T. (April 5, 2005). "Potential of silver nanoparticle-coated polyurethane foam as an antibacterial water filter". Biotechnol. Bioeng. 90 (1): 59–63. doi:10.1002/bit.20368.

- ↑ Surface-Independent Antibacterial Coating Using Silver Nanoparticle-Generating Engineered Mussel Glue

- ↑ Active Silver Nanoparticles for Wound Healing

- ↑ Silver Nanoparticles Could Give Millions Microbe-free Drinking Water, Cara Giaimo on Tue, 24 Mar 2015, PBS NOVA Next

- ↑ Affordable water purification using silver nanoparticles, May 07, 2013 03:14 Updated: October 10, 2016 09:24; R. Prasad; The Hindu

- 1 2 3 4 5 "LG Electronics applies the innovative nano technology to its home appliances". PHYS. July 1, 2004.

- 1 2 3 4 Noorden, Richard (December 22, 2006). "Nano-hype comes out in the wash". Chemistry World.

- 1 2 3 Cheon, Jin Min; Lee, Jin Ha; Song, Yongsul; Kim, Jongryoul (September 20, 2011). "Synthesis of Ag nanoparticles using an electrolysis method and application to inkjet printing". Colloids and Surfaces A: Physicochemical and Engineering Aspects. 389 (1-3): 175–159. doi:10.1016/j.colsurfa.2011.08.032.

- 1 2 3 4 5 6 Sellers, Kathleen; Mackay, Christopher; Bergeson, Lynn L.; Clough, Stephen R.; Hoyt, Marilyn; Chen, Julie; Henry, Kim; Hamblen, Jane (July 30, 2008). Nanotechnology and the Environment. Boca Raton, Florida: CRC Press, LLC. pp. 157–158. ISBN 9781420060195.

- ↑ Ahamed M, Alsalhi MS, Siddiqui MK, Alsalhi, Siddiqui (2010). "Silver nanoparticle applications and human health". Clin. Chim. Acta. 411 (23–24): 1841–1848. doi:10.1016/j.cca.2010.08.016. PMID 20719239.

- ↑ Gopinath P., Gogoi S.K., Sanpuic P., Paul A., Chattopadhyay A., Ghosh S.S. (2010). "Signaling gene cascade in silver nanoparticle induced apoptosis". Colloids Surf. B. 77: 240–5. doi:10.1016/j.colsurfb.2010.01.033.

- ↑ Wise JP, Goodale BC, Wise SS et al. (2010). "Silver nanospheres are cytotoxic and genotoxic to fish cells". Aquat Toxicol. 97: 34–41. doi:10.1016/j.aquatox.2009.11.016.

- 1 2 Foldbjerg R, Oleson P, Hougaard M, Dang DA, Hoffmann HJ, Autrup H (2009). "PVP-coated silver nanoparticles and silver ions induce reactive oxygen species, apoptosis and necrosis in THP-1 monocytes". Toxicol Lett. 190: 156–162. doi:10.1016/j.toxlet.2009.07.009.

- 1 2 3 4 5 Park EJ, Yi J, Kim Y, Choi K, Park K (2010). "Silver nanoparticles induce cytotoxicity by a Trojan-horse type mechanism". Toxicol In Vitro. 97: 34–41. doi:10.1016/j.tiv.2009.12.001.

- 1 2 3 4 5 6 AshRani, P.V.; Low Kah Mun, Grace; Hande, Manoor Prakash; Valiyaveettil, Suresh (December 30, 2008). "Cytotoxicity and Genotoxicity of Silver Nanoparticles in Human Cells". ACS Nano. 3 (2): 279–290. doi:10.1021/nn800596w.

- 1 2 Kittler S.; Greulich C.; Diendorf J.; Köller M.; Epple M. (2010). "Toxicity of silver nanoparticles increases during storage because of slow dissolution under release of silver ions". Chem. Mater. 22 (16): 4548–4554. doi:10.1021/cm100023p.

- ↑ Hussain, S.M.; Hess, K.L.; Gearhart, J.M.; Geiss, K.T.; Schlager, J.J. (October 2005). "In vitro toxicity of nanoparticles in BRL 3A rat liver cells". Toxicol. In Vitro. 19 (7): 975–983. doi:10.1016/j.tiv.2005.06.034.

- ↑ Miura N, Shinohara Y (2009). "Cytotoxic effect and apoptosis induction by silver nanoparticles in HeLa cells". Biochem Biophys res Commun. 390: 733–7. doi:10.1016/j.bbrc.2009.10.039.

- ↑ Laban G, Nies LF, Turco RF, Bickham JW, Sepulveda MS (2009). "The effects of silver nanoparticles on fathead minnow (Pimephales promelas) embryos". Ecotoxicology. 19: 185–195. doi:10.1007/s10646-009-0404-4.

- ↑ Kim S, Choi JE, Choi J et al. (2009). "Oxidative stress-dependent toxicity of silver nanoparticles in human hepatoma cells". Toxicol In Vitro. 23: 1076–84. doi:10.1016/j.tiv.2009.06.001.

- 1 2 Asharani PV, Wu YL, Gong Z, Valiyaveettil S (2008). "Toxicity of silver nanoparticles in zebrafish models". Nanotechnology. 19: 255102. Bibcode:2008Nanot..19y5102A. doi:10.1088/0957-4484/19/25/255102.

- ↑ Johnston HJ, Hutchison G, Christensen FM, Peters S, Hankin S, Stone V; Hutchison; Christensen; Peters; Hankin; Stone (April 2010). "A review of the in vivo and in vitro toxicity of silver and gold particulates: particle attributes and biological mechanisms responsible for the observed toxicity". Crit. Rev. Toxicol. 40 (4): 328–46. doi:10.3109/10408440903453074. PMID 20128631.

- ↑ Ahamed M, Alsalhi MS, Siddiqui MK; Alsalhi; Siddiqui (December 2010). "Silver nanoparticle applications and human health". Clin. Chim. Acta. 411 (23–24): 1841–8. doi:10.1016/j.cca.2010.08.016. PMID 20719239.

- ↑ Thiago Verano-Braga, Rona Miethling-Graff, Katarzyna Wojdyla, Adelina Rogowska-Wrzesinska, Jonathan R. Brewer, Helmut Erdmann, Frank Kjeldsen; Miethling-Graff; Wojdyla; Rogowska-Wrzesinska; Brewer; Erdmann; Kjeldsen (2014). "Insights into the Cellular Response Triggered by Silver Nanoparticles Using Quantitative Proteomics". ACS Nano. 8 (3): 2161–75. doi:10.1021/nn4050744. PMID 24512182.

- ↑ Chuang; et al. "Allergenicity and toxicology of inhaled silver nanoparticles in allergen-provocation mice models". International Journal of Nanomedicine. 2013 (8): 4495–4506. doi:10.2147/IJN.S52239.

- ↑ Hirai; et al. (2014). "Silver nanoparticles induce silver nanoparticle-specific allergic responses (HYP6P.274)". The Journal of Immunology. 192 (118): 19.

- ↑ Trop, Marji, Michael Novak, Siegfried Rodl, Bengt Hellbom, Wolfgang Kroell, and Walter Goeseeler (2006). "Silver-coated dressing acticaot caused raised liver enzymes and argyris-like symptoms in burn patient". The Journal of Trauma, Injury, Infection and Critical Care. 60 (3): 648–652. doi:10.1097/01.ta.0000208126.22089.b6.

- ↑ Parkes, A. (2006). "Silver-coated dressing Acticoat". Journal of Trauma-Injury Infection & Critical Care. 61 (1): 239–40. doi:10.1097/01.ta.0000224131.40276.14.

- ↑ Horstkotte, D.; Bergemann, R. (2001). "Thrombogenicity of the St. Jude medical prosthesis with and without silzone-coated sewing cuffs". The Annals of thoracic surgery. 71 (3): 1065. doi:10.1016/S0003-4975(00)02363-8. PMID 11269440.