Rolls-Royce Pegasus

| Pegasus / F402 | |

|---|---|

| | |

| Rolls-Royce Pegasus on display at the Royal Air Force Museum London | |

| Type | Turbofan |

| National origin | United Kingdom |

| Manufacturer | Rolls-Royce |

| First run | September 1959 |

| Major applications | Hawker Siddeley Harrier BAE Sea Harrier McDonnell Douglas AV-8B Harrier II |

| Number built | over 1,200 (through 2008) |

| Developed from | Bristol Siddeley Orpheus |

The Rolls-Royce Pegasus, formerly the Bristol Siddeley Pegasus, is a turbofan engine originally designed by Bristol Siddeley. It was manufactured by Rolls-Royce plc. The engine is not only able to power a jet aircraft forward, but also to direct thrust downwards via swivelling nozzles.[1] Lightly loaded aircraft equipped with this engine can manoeuvre like a helicopter. In particular, they can perform vertical takeoffs and landings.[2] In US service, the engine is designated F402.

The unique Pegasus engine powers all versions of the Harrier family of multi-role military aircraft. Rolls-Royce licensed Pratt & Whitney to build the Pegasus for US built versions. However Pratt & Whitney never completed any engines, with all new build being manufactured by Rolls-Royce in Bristol, England. The Pegasus was also the planned engine for a number of aircraft projects, among which were the prototypes of the German Dornier Do 31 VSTOL military transport project.[3]

Development

Background

Michel Wibault, the French aircraft designer, had the idea to use vectored thrust for vertical take-off aircraft. This thrust would come from four centrifugal blowers shaft driven by a Bristol Orion turboprop, the exhaust from each blower being vectored by rotating the blower scrolls.[4] Although the idea of vectoring the thrust was quite novel, the engine proposed was considered to be far too heavy.[5]

As a result, an engineer at Bristol Engine Company, Gordon Lewis, began in 1956 to study alternative engine concepts, where possible, existing engine components from the Orpheus and Olympus engine series. The work was overseen by the Technical Director Stanley Hooker. One concept which looked promising was the BE52, which initially used the Orpheus 3 as the engine core and, on a separate coaxial shaft, the first 2 stages of an Olympus 21 LP compressor, which acted as a fan, delivering compressed air to 2 thrust vectoring nozzles at the front of engine. At this point in design exercise, the exhaust from the LP turbine discharged through a conventional rear nozzle. There was separate intakes for the fan and core compressor because the fan did not supercharge the core compressor.

While the BE.52 was a self-contained powerplant and lighter compared to Wibault's concept, the BE.52 was still complicated and heavy. As a result, work on the BE.53 concept started in February 1957. In the BE.53 the Olympus stages were fitted close to the Orpheus stages; thus simplifying the inlet ducting. The Olympus stages now supercharged the Orpheus core, thus improving the overall pressure ratio.,[6] creating what is now considered a conventional turbofan configuration.

For a year Bristol designed the engine in isolation, with little feedback from the various airframers furnished with data. However, in May 1957 the team received a supportive letter from Sydney Camm of Hawker Aviation They were looking for a Hawker Hunter replacement. The aircraft designer, Ralph Hooper, suggested having the four thrust vectoring nozzles (originally suggested by Lewis), with hot gases from the rear two. Further joint discussions helped to refine the engine design.

The 1957 Defence White Paper, which focused on missiles, and not manned aircraft - which were declared 'obsolete', also was not good news, because it precluded any future government financial support for development of non-already extant manned combat aircraft, and so prevented any official financial support for the engine/airframe from the Ministry of Defence.[7] Fortunately engine was financially supported to the tune of 75% from the Mutual Weapons Development Programme, Verdon Smith of Bristol Siddeley Engines Limited (BSEL), which Bristol Engines had by then become on its merger with Armstrong Siddeley, quickly agreeing to pay the remainder.[7]

The first prototype engine (one of two BE53/2's built), ran on 2 September 1959 and featured a 2-stage fan and used the Orpheus 6 core. Although the fan was overhung, inlet guide vanes were still incorporated. The HP spool comprised a 7-stage compressor driven by a single stage turbine. A 2-stage LP turbine drove the fan. There was no plenum at fan exit, but 4 thrust vectoring nozzles were fitted.

Further development of the engine then proceeded in tandem with the airframe, the Hawker P.1127. The aircraft first flew (tethered hover) on 21 October 1960 and was powered by the BE53/3 (Pegasus 2). Free hover was achieved on 19 November of the same year. Transition to wing-borne flight occurred in 1961. Later versions of the P.1127 were fitted with the Pegasus 3 and eventually the Pegasus 5.

The Pegasus 5 was also used in the Kestrel, a refinement of the P.1127, of which nine were built for the Tripartite evaluation exercise. The Kestrel was subsequently developed into the Harrier combat aircraft. By the time the Pegasus 5/2 was built, both the fan and HP compressor had been zero-staged and 2nd stage added to the HP turbine.

Testing and production

The flight testing and engine development received no government funding; the plane's funding came entirely from Hawker. There was only enough thrust in the first engines to barely lift the plane off the ground because of weight growth problems. Flight tests were conducted when the aircraft was tethered. The first free hover was achieved on 19 November 1960. The first, and difficult, transition from static hover to conventional flight was achieved on 8 September 1961. The RAF was not much of a convert to the VTOL idea, and described the whole project as a toy and a crowd pleaser. The first prototype P1127 made a very heavy landing at the Paris Air Show in 1963.

Series Manufacture and Design and Development improvement to ever higher thrusts of the Pegasus was continued by Bristol engines beyond 1966, which was when Rolls-Royce Ltd bought the Company. A related engine design, the 39,500 lbf (with reheat) Bristol Siddeley BS100 for a supersonic VTOL fighter (the Hawker Siddeley P.1154) was not developed to production as the aircraft project was cancelled in 1965.

To date, 1,347 engines have been produced and two million operating hours have been logged with the Harriers of the Royal Air Force (RAF), Royal Navy, U.S. Marine Corps and the navies of India, Italy, Spain and Thailand.

A non-vectored 26,000 lb thrust derivative of the Pegasus running on liquid hydrogen, the RB.420, was designed and offered in 1970 in response to a NASA requirement for an engine to power the projected Space Shuttle on its return flight through the atmosphere. In the event, NASA chose a design using an un-powered gliding return for the resultant vehicle.[8]

Design

_launches_from_the_flight_deck_of_amphibious_assault_ship_USS_Bataan_(LHD_5).jpg)

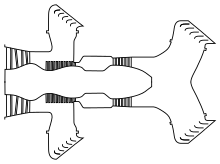

The Pegasus vectored-thrust turbofan is a two-shaft design featuring three low pressure (LP) and eight high pressure (HP) compressor stages driven by two LP and two HP turbine stages respectively. Unusually the LP and HP spools rotate in opposite directions to greatly reduce the gyroscopic effects which would otherwise hamper low speed handling. LP and HP fan blading is titanium, the LP fan blades operating in the partly supersonic region, and airflow is 432 lb/s.[7] The engine employs a simple thrust vectoring system that uses four swiveling nozzles, giving the Harrier thrust both for lift and forward propulsion, allowing for STOVL flight.

Combustion system is an annular combustor with ASM low-pressure vaporising burners.[7]

Engine starting was by a top-mounted packaged combined gas turbine starter/APU.[7]

Nozzles

The front two nozzles, which are of steel, are fed with air from the LP compressor, the rear nozzles, which are of Nimonic[7] with hot (650 °C) jet exhaust. The airflow split is about 60/40 front back.[9] It was critical that the nozzles rotate together. This was achieved by using a pair of air motors fed from the HP (high pressure) compressor, in a fail over configuration, pairs of nozzles connected with, surprisingly, motor-cycle chains. The nozzles rotate over an angular range of 98.5 degrees.[7]

The Pegasus was also the first turbofan engine to have the initial compressor fan, the zero stage, ahead of the front bearing. This eliminated radial struts and the icing hazard they represent.

Position of the engine

The engine is mounted in the centre of the Harrier and as such it is necessary to remove the wing to change the powerplant having already sat the fuselage on trestles; the whole change took a minimum of eight hours[10] although using the proper tools and lifting equipment this could be accomplished in less than four.[11]

Water Injection

The maximum take-off thrust available from the Pegasus engine is limited, particularly at the higher ambient temperatures, by the turbine blade temperature. As this temperature cannot reliably be measured, the operating limits are determined by jet pipe temperature. To enable the engine speed and hence thrust to be increased for take-off, water is sprayed into the combustion chamber and turbine to keep the blade temperature down to an acceptable level.

Water for the injection system is contained in a tank located between the bifurcated section of the rear (hot) exhaust duct. The tank contains up to 500 lb (227 kg, 50 imperial gallons) of distilled water. Water flow rate for the required turbine temperature reduction is approximately 35gpm (imperial gallons per minute) for a maximum duration of approximately 90 seconds. The quantity of water carried is sufficient for and appropriate to the particular operational role of the aircraft.

Selection of water injection engine ratings (Lift Wet/Short Lift Wet) results in an increase in the engine speed and jet pipe temperature limits beyond the respective dry (non-injected) ratings (Lift Dry/Short Lift Dry). Upon exhausting the available water supply in the tank, the limits are reset to the 'dry' levels. A warning light in the cockpit provides advance warning of water depletion to the pilot.

Variants

Pegasus 1

The two prototype engines, also known as BE53-2's, were demonstrator engines which developed about 9,000 lbf (40 kN) on the test bed. Neither engine was installed in the P.1127.

Pegasus 2

Otherwise known as the BE53-3, used in the initial P.1127's, 11,500 lbf (51 kN)

Pegasus 3

Used on the P.1127 prototypes, 13,500 lbf (60 kN)

Pegasus 5

Or BS.53-5 (Bristol-Siddeley 53-3). Used for the Hawker Siddeley Kestrel evaluation aircraft. 15,000 lbf (67 kN)

Pegasus 6 (Mark 101)

For first Harriers. 19,000 lbf (85 kN), first flown in 1966 and entered service 1969

Pegasus 10 (Mark 102)

For updating first Harriers with more power and used for the AV-8A, 20,500 lbf (91 kN), entering service in 1971.

Pegasus 11 (Mark 103)

The Pegasus 11 powered the first generation Harriers, the RAF's Hawker Siddeley Harrier GR.3, the USMC AV-8A and later the Royal Navy's Sea Harrier. The Pegasus 11 produced 21,000 lbf (93 kN) and entered service in 1974.

Pegasus 14 (Mark 104)

Navalised version of the Pegasus 11 for the Sea Harrier, same as the 11 but some engine components and castings made from corrosion-resistant materials.

Pegasus 11-21/Mk.105/Mk.106

The 11-21 was developed for the second generation Harriers, the USMC AV-8B Harrier II and the BAE Harrier IIs. The original model provided an extra 450 lbf (2.0 kN). The RAF Harriers entered service with the 11-21 Mk.105, the AV-8Bs with F402-RR-406. Depending on time constraints and water injection, between 14,450 lbf (64.3 kN) (max. continuous at 91% RPM) and 21,550 lbf (95.9 kN) (15 s wet at 107% RPM) of lift is available at sea level (including splay loss at 90°).[12]

The Mk.106 development was produced for the Sea Harrier FA2 upgrade and generates 21,750 lbf (96.7 kN).

Pegasus 11-61/Mk.107

The 11-61 (aka -408) is the latest and most powerful version of the Pegasus, providing 23,800 lbf (106 kN).[13] This equates to up to 15 percent more thrust at high ambient temperatures, allowing upgraded Harriers to return to an aircraft carrier without having to dump any unused weapons which along with the reduced maintenance reduces total cost of engine use.

This latest Pegasus has also enabled a highly effective radar equipped AV-8B+. This version combines the proven advantages of day and night STOVL operations with an advanced radar system and beyond-visual-range missiles. The RAF/RN was in the process of upgrading its GR7 fleet to GR9 standard, initially through the Joint Upgrade and Maintenance Programme (JUMP) and then through the Harrier Platform Availability Contract (HPAC). All GR7 aircraft were expected to have been upgraded by April 2010. Part of this process was the upgrade of the Mk.105 engines to Mk.107 standard. These aircraft were known as GR7As and GR9As.

Applications

- AV-8B Harrier II

- BAE Sea Harrier

- BAE Harrier II

- Dornier Do 31

- Hawker Siddeley Harrier

- Hawker Siddeley P.1127

- Intended application

Engines on display

Pegasus engines are on public display at the following museums:

- Imperial War Museum Duxford

- Royal Air Force Museum London

- Science Museum (London)

- National Naval Aviation Museum Pensacola, Florida

- Naval Aviation Museum (India), Goa, India

- Deutsches Museum, Munich, Germany

- Rolls-Royce Heritage Trust, Allison,Indianapolis, Indiana

Specifications (Pegasus 11-61)

Data from [14]

General characteristics

- Type: Twin-spool turbofan

- Length: 137 in (3.480 m)

- Diameter: 48 in (1.219 m)

- Dry weight: 3,960 lb (1,796 kg)

Components

- Compressor: 3-stage low pressure, 8-stage high pressure axial flow

- Combustors: Annular

- Turbine: 2-stage high pressure, 2-stage low pressure

Performance

- Maximum thrust: 23,800 lbf (106 kN)

- Overall pressure ratio: 16.3:1

- Specific fuel consumption: 0.76 lb/lbf-hr

- Thrust-to-weight ratio: 6:1

See also

- Related development

- Comparable engines

- Related lists

References

- Citations

- ↑ Bolkcom, C. "F-35 Joint Strike Fighter (JSF) Program: Background, Status, and Issues" CRS Report for Congress. (2005). Accessed 14 October 2009.

- ↑ "Air Cadet Publication 33: Flight - Volume 3 Propulsion" 282 East Ham Squadron - Air Training Corps. (2000). Accessed 14 October 2009.

- ↑ Flight 23 April 1964 p. 668

- ↑ "Bristol Siddeley's Fans" Flight 12 August 1960 p210-211

- ↑ Pegasus: the Heart of the Harrier, Andrew Dow, Pen & Sword, ISBN 978-1-84884-042-3

- ↑ Flight 12 August 1960

- 1 2 3 4 5 6 7 "World Encyclopedia of Aero Engines - 5th edition" by Bill Gunston, Sutton Publishing, 2006, p.39

- ↑ https://books.google.co.uk/books?id=qTLAAwAAQBAJ&pg=PA290&lpg=PA290&dq=Pegasus,+The+Heart+of+the+Harrier:+The+History+and+Development&source=bl&ots=RVPjkXqLl9&sig=Y6_nkhLqw1BsP534TD7oU_1mgmk&hl=en&sa=X&ei=RL3kVJz0NsLlas3ZgGA&ved=0CFkQ6AEwCQ#v=onepage&q=Pegasus%2C%20The%20Heart%20of%20the%20Harrier%3A%20The%20History%20and%20Development&f=false

- ↑ Flight August 1964 p. 328

- ↑ Eight hour engine change

- ↑ http://www.flightglobal.com/pdfarchive/view/1971/1971%20-%201857.html

- ↑ AV-8B Standard Aircraft Characteristics US Naval Air Systems Command, October 1986. Retrieved: 16 April 2010.

- ↑ Pegasus - Power for the Harrier RR website, 2004. Retrieved: 17 April 2010.

- ↑ Gas Turbine Engines. Aviation Week & Space Technology Source Book 2009. p 123.

- Bibliography

- Pegasus: the Heart of the Harrier, Andrew Dow, Pen & Sword, ISBN 978-1-84884-042-3

- Not Much of an Engineer, Sir Stanley Hooker, Airlife Publishing, ISBN 0-906393-35-3

- Powerplant: Water Injection System, Aircraft Engineering and Aerospace Technology, Vol. 42 Iss: 1, pp: 31 - 32. DOI: 10.1108/eb034594 (Permanent URL). Publisher: MCB UP Ltd

External links

| Wikimedia Commons has media related to Rolls-Royce Pegasus. |

- Harrier.org.uk, Pegasus engine variants

- A 1960 Bristol advertisement for the BS 53 Turbofan

- 50th anniversary in September 1959

- Early ideas for vertical take off

- Flight Bristol Siddeley Developments IN THE V/STOL POWERPLANT FIELD 1964

- "Designing the Pegasus" a 1972 Flight article by Bill Gunston

- "Pegasus Updating Prospects" a 1977 Flight article on improvements to the Pegasus