Performance fabrics

Performance fabrics are fabrics engineered for a wide variety of uses where the performance of the fabric is the major parameter. Performance fabrics may be used in for all active wear, sports wear, summer and winter wear, mountain activities, trekking, work wear, in military, as well as urban wear and protective wear. Performance fabrics are meant for providing extra comfort and protection[1] to the wearer under normal to extreme conditions.

The performance of the fabric/garment is enhanced or achieved by a number of processes like selection of fibers and blending of the performance fibers during spinning, knitting or weaving along with other yarns like cotton, viscose, bamboo, polyester, acrylic, nylon, and elastane and also by processing and finishing with chemicals (also known as functional finishes)[2][3] during dyeing or at finishing stages by padding or coating and some of them also possible at the garment stage. Nanotechnology can provide high durability for Performance fabrics,because nano-particles have a large suface area-to -volume ratio and high surface energy,thus presenting better affinity for fabrics and leading to an increase in durability of the function.The potential of nanotechnology in the development of new materials in the textile industry is considerable. On the one hand, existing functionality can be improved using nanotechnology and on the other, it could make possible the manufacture of textiles with entirely new properties or the combination of different functions in one textile material[4]

These fabrics are also known as value-added textiles. The high performance and cost-effectiveness of smart fabrics and interactive textiles have enabled them to replace traditional materials and become popular among many end-users.The author analysts forecast the global smart fabrics and interactive textiles market to grow at a CAGR of 20.18% by revenue during 2014–2019.[5] These fabrics can perform extraordinarily different than their natural behavior or what they were meant for. For example, a polyester garment can absorb water like cotton and a cotton trouser can gain the ability to repel water[6] (both of these characteristics differ from their original nature). Smart textiles are an advanced type of performance fabrics.

Usage

These fabrics may have dual or multi-functionality so they are primarily used to increase the fabric's versatility.[7] Sporting apparel moving out of the sports wear context and into fashionable street wear, for example yoga leggings may be used as casual wear.[8] Also, active-wear can also be used for the purpose of formal clothing or casual clothing, and one fabric may certify all the criterion used to judge a fabric's appeal—for example, style, feel, comfort, appearance, flexibility and utility.[9]

High performance fabrics, (such as those which are both flexible and flame retardant) are being used in the armed forces, in firefighting forces, and in the welding industry.[1] They are also used for making workwear for industrial purposes due to their stain repellancy.

Characteristics

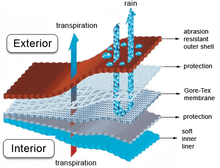

Different performance fabrics have various characteristics. Some varieties of performance fabrics are capable of blocking harmful ultraviolet radiation,[10] and they often have protection from ticks and mosquitoes, moisture wicking,Quick Dry, temperature control and antimicrobial and anti-odor properties.[11][12][13] Performance fabrics may also possess pilling-resistance,Antistatic, wrinkle resistance, stain (water, dirt and oil) resistance,Self cleaning[14] and flame retardation.[1][13] In some cases, they can be resistant to wind, heat and abrasion.

See also

References

- 1 2 3 Claudia Ollenhauer (September 2013). Personal Protection Textiles (2nd ed.). ISBN 978-0-9573-6163-8.

- ↑ "Functional Finishes and Coatings for Performance Textiles". AATCC. Archived from the original on October 17, 2013.

- ↑ "Performance Enhancement of Textile Fabrics" (PDF). AATCC. Archived from the original (PDF) on April 20, 2014.

- ↑ http://www.nanowerk.com/spotlight/spotid=19451.php

- ↑ ltd, Research and Markets (July 2015). "Global Smart Fabrics and Textiles Market 2015-2019".

- ↑ https://www.newscientist.com/article/dn16126-nanotech-clothing-fabric-never-gets-wet/

- ↑ "What's Up With Today's Active Wear?". The Robin Report. 17 July 2012.

- ↑ Pasquarelli, Adrianne (July 10, 2011). "Activewear makes it onto the runway". Crain's New York Business.

- ↑ "Fashion Meets Function in Bemis Associates and CORDURA® Fabric's Collaborative Collection at Summer Outdoor Retailer 2015". Business Wire. August 5, 2015.

- ↑ "Players to wear special caps for Midsummer Classic in ode to Cincinnati baseball". The Highland County Press. Cameco Communications. 17 June 2015. Retrieved 22 August 2015.

- ↑ "Antibacterial & Odor Control: Marketing and Technology Advancements Conference". AATCC. Archived from the original on May 12, 2015.

- ↑ Fetters, K. Aleisha (11 April 2015). "Are You Washing Your Workout Clothes Properly?". HuffPost Healthy Living. The Huffington Post. Retrieved 22 August 2015.

- 1 2 Easter, Elizabeth P. (June 2008). "High-performance fabrics for commercial upholstery". Upholstery Journal. Industrial Fabrics Association International. Retrieved 22 August 2015.

- ↑ http://www.nanowerk.com/spotlight/spotid=19451.php

External links

- DuPont Company Textile Fabrics Department videotapes, photographs, slides and promotions (1918-2004) at Hagley Museum and Library.

- Moisture Management