International Harvester IDI

| International Harvester IDI | |

|---|---|

| Overview | |

| Manufacturer |

International Harvester (1982–1986) Navistar International (1987–1994) |

| Production |

1982–1987 (6.9 L) 1988–1994 (7.3 L) |

| Combustion chamber | |

| Configuration | V8 |

| Displacement |

420 cubic inches (6.9 L) 444 cubic inches (7.3 L) |

| Cylinder bore |

4.0 inches (6.9 L) 4.11 inches (7.3 L) |

| Piston stroke |

4.18 inches (6.9 L) 4.18 inches (7.3 L) |

| Cylinder block alloy | Iron |

| Cylinder head alloy | Iron |

| Valvetrain | OHV |

| Combustion | |

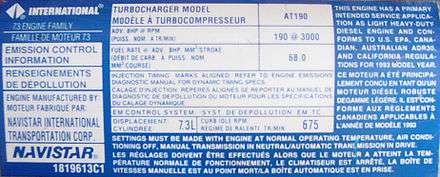

| Turbocharger | Optional Single turbocharger (1993–1994 Only) |

| Fuel system | Indirect injection |

| Management | Mechanical |

| Fuel type | Diesel |

| Oil system | 10.0 Quarts |

| Cooling system | 29.0 Quarts |

| Output | |

| Specific power |

170 @ 3,300 RPM (6.9 L) 185 @ 3,000 RPM (7.3 L) 190 @ 3,000 RPM (7.3 L turbo) |

| Torque output |

315 ft·lb @ 1,400 RPM (1983 & Earlier 6.9L) 338 ft-lb @ 1,400 RPM (1984 & Later)(6.9 L) 338 ft·lb @ 1,800 RPM (7.3 L) 388 @ 1,400 RPM (7.3 L turbo) |

| Chronology | |

| Successor |

Navistar T444E Ford Power Stroke V8 |

The International Harvester IDI (from Indirect Injection) engine is a 4-stroke 8-cylinder Diesel engine used in International Harvester trucks, Ford F-Series pickups, and Ford E-Series vans from 1983 to 1994. The engine had two displacements: 420 cubic inches (6.9 litres), which was used in Ford trucks from 1983 until 1987, and 444 cubic inches (7.3 litres), which was used in Ford trucks from 1988 until 1994 (naturally aspirated) and in 1993 and 1994 (turbocharged). These engines were replaced in 1994.5 by the Navistar T444E (7.3 L) engine, which was also marketed under the Ford Power Stroke name.

History

In 1981 Ford signed an agreement with International Harvester to produce diesel engines for their light truck line. This led directly to the production of the 6.9 liter IDI diesel. The engine is developed as a low cost, light weight diesel that fit where a V8 gas engine would, to try to convert their gas engine customers to diesel and to sell to Ford for use in F-Series light duty trucks and E-Series/Econoline vans. Before it could be sold to Ford however, Tenneco Inc. purchased in the "Harvester" division of International Harvester which was moved within their Case heavy equipment line. The remainder of what was International Harvester was renamed Navistar, which concentrated on engine and medium/heavy truck development. Consequently, these are actually International-Navistar IDI engines.

6.9L

During the 1983 model year, the F250 and F350 trucks were first available with the 6.9L diesel engine. This was the first diesel engine offered in Ford light-duty pickups. Although the GM pickups already had offered a diesel engine option a year prior, the GM diesel engine was intended for efficiency over power. On the other hand, the 6.9L diesel made decent power compared to its peers, therefore, it became a feasible replacement to big-block gas engines. The 6.9L engine was naturally aspirated and put out 170 hp @ 3,300 RPM and 315 lb-ft @ 1,400 RPM.

7.3L

In 1987, the 6.9 liter engine was supplanted by the 7.3 liter upgrade, with over 300,000 6.9s shipped to Ford and countless numbers installed into medium-duty trucks, school buses, and the like. This engine features numerous improvements over the 6.9 liter, with most of the changes located in the heads; the block received an increase bore and select-fit pistons, while the heads received an enlarged prechamber, enlarged valve stem shields, harder valves, and other minor upgrades. The front cover was revised to reduce seepage.

Finally, in 1993 Ford made available a turbocharged edition of the 7.3L. An internally wastegated, AR.82 Garrett T3 series turbo was used as the OEM for the factory turbocharger system. The system was tuned to minimize performance loss at high elevation, rather than to improve peak performance. A primary limiting factor to the performance potential of the engine is an incredibly restrictive stock down-pipe. It is commonly believed, but not officially verified, that this is deliberate and due to Ford's impending release of the T444E (Powerstroke) engine. Factory turbo vehicles received numerous additional improvements. Pistons had an enlarged primary compression ring, added intermediate ring, an enlarged ring land and wrist pin, as well as an anodized piston face. Other improvements included tweaks to the injection pump, and an upgraded oil-coolant heat exchanger.[1]

Fuel system

These engines use an injection pump that is entirely mechanical, this was the standard for diesels of the day. The fuel system also utilizes indirect injection which made it quieter than mechanically direct injected engines. Both 6.9 and 7.3 liter engines use the Stanadyne DB-2 injection pump fed by a cam-driven lift pump.

References

- ↑ "7.31 IDI Turbocharged Diesel Engine" (PDF). http://www.fokisd.org. Ford. External link in

|work=(help)

- Brewer, Tom (October 23, 2008). "Know your IDI History, Ford Diesel - 101", http://www.moddedraptor.com/, Retrieved from http://www.moddedraptor.com/community/off-topic/2805-know-your-idi-history-ford-diesel-101-a.html

http://www.thedieselfiles.com http://www.thedieselfiles.com/Ford/69lupdatepart4.pdf http://www.dieselpowermag.com/tech/ford/0810dp_ford_diesel_truck/