Zinc mining in the United States

Zinc mining in the United States produced an all-time high of 820,000 metric tons of zinc in 2014, making it the world's fourth-largest zinc producer, after China, Australia, and Peru. Most US zinc came from the Red Dog mine in Alaska. The industry employed about 2,600 in mining, and 257 in smelting.[1]

Current zinc-mining districts

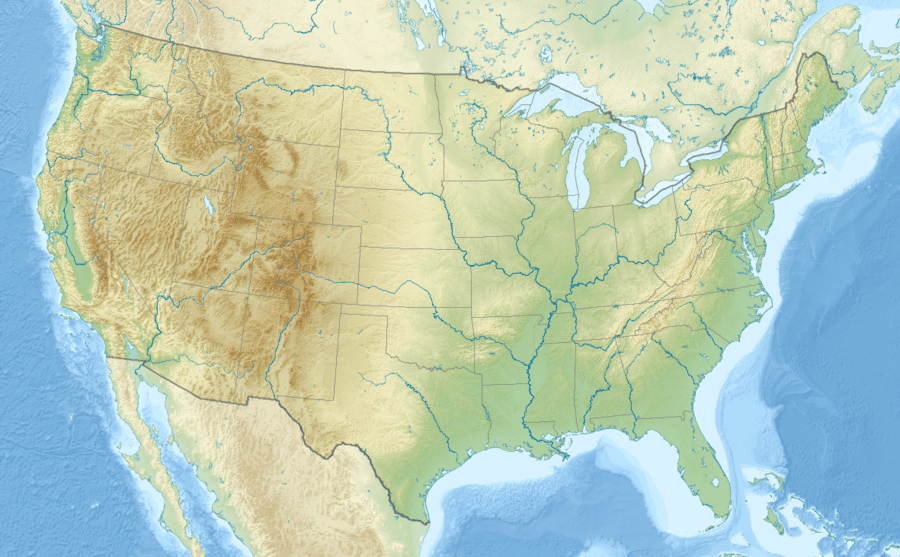

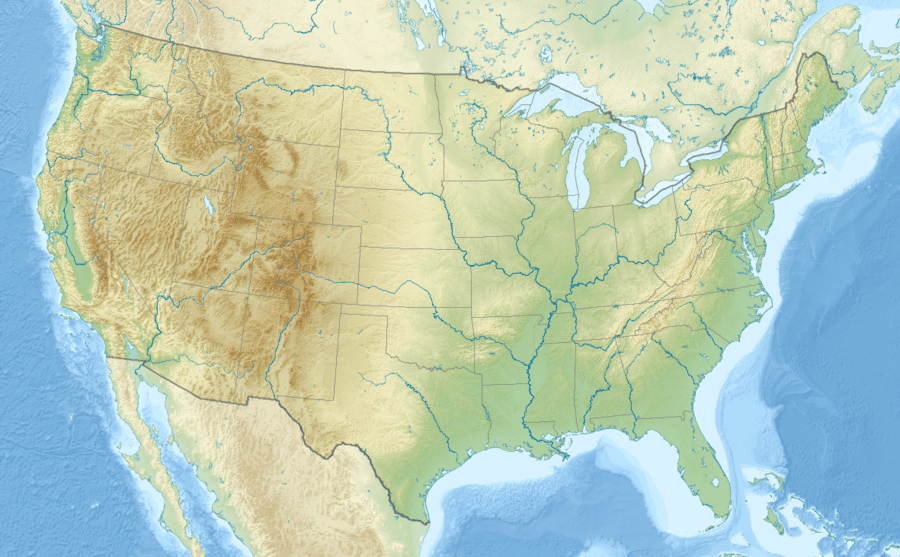

Red Dog Mine, Alaska

In 2014, 609,000 metric tons of zinc, 78 percent of US mined zinc production, and 4.6 percent of world zinc production, came from the Red Dog mine in northern Alaska, which was the world's second most productive zinc mine in 2014, after the Rampura Agucha mine in India. The mine opened in 1989.[2] The zinc was shipped as concentrate to foreign smelters. The Red Dog is a polymetallic deposit, which also produced lead and silver.

Middle and east Tennessee districts

In middle and east Tennessee, six mines produced zinc from Mississippi Valley-type deposits. The mines were: the Coy, Immel, and Young mines in east Tennessee, and the Gordonsville, Elmwood, and Cumberland mines in middle Tennessee.

Metaline district

In Washington's Metaline mining district, the Pend Oreille Mine produced zinc, starting in 2014.

Coeur D'Alene district, Idaho

At the Coeur D'Alene district in northern Idaho, zinc is produced as a byproduct of silver mining.

Admiralty Island, Alaska

The The Greens Creek Mine on Admiralty Island, Alaska, opened in 2014.

Former zinc-mining districts

Tri-state district:

- The Tri-State district of Missouri, Oklahoma and Kansas was a major zinc mining district from the 1850s through the 1960s.

Southeast Missouri lead district:

- Zinc was produced as a byproduct of lead mining in the Southeast Missouri Lead District.

Austinville, Virginia:

- The Austinville-Ivanhoe District was a zinc mining district in Wythe County, Virginia.

Smelting

Primary smelters produce metal from ore. The only American primary zinc smelter, the Nyrstar smelter at Clarksville, Tennessee, produced 115 metric tons of zinc, from a mix of ore from six mines in middle and east Tennessee, and recycled zinc products.

Secondary zinc smelters produce zinc from recycled materials. A secondary zinc smelter in Pennsylvania closed in 2014, the operations being shifted to a new smelter in North Carolina using solvent extraction/electrowinning (SX/EW). In addition, some non-smelting zinc recycling operations produced small amounts of zinc. The total amount of zinc produced from secondary operations was 70 tons. For primary and secondary smelters taken together, recycled products accounted for 52 percent of the refined zinc produced in US in 2014.[3]

Through 1940, the production of primary zinc by US smelters approximated the mined production of zinc ore. When zinc demand increased during World War II, US smelters turned to foreign zinc ore. US-smelted zinc reached a high of 926,000 metric tons in 1970, then dropped as smelters closed. There were 12 primary zinc smelters in 1970, but only 7 in 1980, 3 in 1990, and two in 2000. Today, there is only one operating primary zinc smelter, in Clarksville, Tennessee, which produces zinc from mines in the East Tennessee and Middle Tennessee districts. All other zinc ore is exported, and smelted abroad.

Byproducts of zinc

A number of elements are recovered in flue gas and flue dust in zinc smelters. These include the metal cadmium and the semi-metals gallium and germanium. In 1970, for every ton of zinc produced at a US smelter, there were also recovered 4.2 kilograms of cadmium, 53 grams of germanium, 18 grams of indium, and 2.9 grams of thallium.[4] These elements are concentrated as impurities in the zinc mineral sphalerite. The elements are more abundant in sphalerite from ore deposits with lower formation temperatures, such as Mississippi Valley-type deposits. The middle- and east-Tennessee zinc mines are Mississippi Valley-type.

Cadmium recovered in zinc smelting is the only commercial source of cadmium. Gallium and germanium are also recovered some from other sulfide ores. Some germanium is also recovered from aluminum smelting. In previous years, indium and thallium were recovered from zinc smelting, but as of 2015, they were not being recovered from American zinc smelters.

According to the British Geological Survey, in 2011, US zinc smelting recovered about 600 metric tons of cadmium, 3 tons of gallium, and 3 tons of germanium.[5]

Consumption

In 2013, the US consumed 935,000 tons of zinc.[6]

Most zinc (AA percent of US consumption) is used for galvanic coating of steel, to prevent rust.

International trade

The United States is a net importer of zinc. In 2013, the nation imported 713,000 metric tons of refined zinc metal and products, primarily from Canada, Mexico, and Peru. In the same year, the US exported 669,000 tons of zinc in concentrated ore, mostly from the Red Dog Mine in Alaska, and imported 2,550 tons of zinc in ore concentrates for the zinc smelter at Clarksville, Tennessee.[7]

References

- ↑ Zinc Mineral Commodity Summary 2015, US Geological Survey.

- ↑ The world's top three zinc mines, Investing News.

- ↑ Zinc, in Minerals Summary 2015, US Geological Survey.

- ↑ R.A. Heindl, '"Zinc," in Mineral Facts and Problems, US Bureau of Mines, Bulletin 650, 1970, p.814.

- ↑ World Mineral Production 2007-11, British Geological Survey, 2013.

- ↑ Zinc, in US Geological Survey, Mineral Yearbook, 2013.

- ↑ 2013 minerals yearbook

.svg.png)