Voided biaxial slab

Voided biaxial slabs are reinforced concrete slabs in which voids reduce the amount of concrete.

While concrete has been used for thousands of years, the use of reinforced concrete is usually attributed to Joseph-Louis Lambot in 1848. Joseph Monier, a French gardener, patented a design for reinforced garden tubs in 1868, and later patented reinforced concrete beams and posts for railway and road guardrails.

The main obstacle with concrete constructions, in case of horizontal slabs, is the high weight, which limits the span. For this reason major developments of reinforced concrete have focused on enhancing the span, either by reducing the weight or overcoming concrete's natural weakness in tension.

An early example is the Pantheon in Rome, built 125 AD. Although not reinforced, coffers were used to reduce the weight.

Biaxial slabs

Focus has been on biaxial slabs and ways to reduce the weight. Several methods have been introduced during the last decades, but with very limited success, due to major problems with shear capacity and fire resistance as well as impractical execution.

For decades, several attempts have been made to create biaxial slabs with hollow cavities in order to reduce the weight. Most attempts have consisted of laying blocks of a less heavy material like expanded polystyrene between the bottom and top reinforcement, while other types included waffle slabs and grid slabs.

Of these types, only waffle slabs can be regarded to have a certain use in the market. But the use will always be very limited due to reduced resistances towards shear, local punching and fire. The idea of placing large blocks of light material in the slab suffers from the same flaws, which is why the use of these systems has never gained acceptance and they are only used in a limited number of projects in Spanish-speaking countries.

Composition

The geometry of the BubbleDeck slab is identified by ellipsoids of a certain size, placed in a precise modular grid. All geometrical parameters of the slab can be described by a single parameter, the modulus named “a”. Modulus and corresponding deck heights are manufactured in steps (modulus in steps of 25 mm, and effective heights in steps of 50 mm)[1]

In principle, fixing of the ellipsoids can be made in numerous ways, but using only the reinforcement meshes reduces superfluous material consumption and allows for an optimal geometrical proportion between concrete, reinforcement and voids.

The voids are positioned in the middle of the cross section, where concrete has limited effect, while maintaining solid sections in top and bottom where high stresses can exist. Hence, the slab is fully functional with regards to both positive and negative bending.

Theory

In principle, voided biaxial slabs act like solid slabs. Designing is consequently like for solid slabs, but with less load corresponding to the reduced amount of concrete. Investigations according to Eurocodes made at universities in Germany, Netherlands and Denmark, conclude that a voided biaxial slabs acts like as a solid slab.[2][3][4][5][6][7][8][9][10]

While a true biaxial slab as the BubbleDeck system must be calculated as a solid slab, ribbed slab systems, like the U-boot system, consisting of a grid of orthogonal "I" beams, must be calculated as beams.

The voided biaxial slabs technology is directly incorporated in international standards as the Eurocodes, and various national codes such as the CUR in the Netherlands.[11]

Shear

The main difference between a solid slab and a voided biaxial slab refers to shear resistance. Due to the reduced concrete volume, the shear resistance will also be reduced. For a voided biaxial slabs with spheres the shear resistance is proportional to the amount of concrete, as the special geometry shaped by the ellipsoidal voids acts like the famous Roman arch, enabling all concrete to be effective. This is only valid when considering the voided biaxial slabs technology. Other types of voided biaxial slabs have reduced resistances towards shear, local punching and fire.

In practice, the reduced shear resistance will not lead to problems, as balls are simply left out where the shear is high, at columns and walls.[12][13][14][15][16][17]

Fire

As U-Boot Beton® is made of polypropylene, it is not toxic even if burnt. Moreover,the slab will not explode due to the escaping of over pressurised gas from the feet (4 feet for each formwork) that act as safety valves. Tests run at the CSI laboratory have demonstrated that with a cement cover of 3 cm the structure created with U-Boot Beton® is class REI 180.

As a voided biaxial slab (with spheres only) acts like a solid slab, the fire resistance is just a matter of the amount of concrete layer. The fire resistance is dependent on the temperature in the rebars and hence the transport of heat. As the top and bottom of the voided biaxial slab is solid, and the rebars are placed in the solid part, the fire resistance can be designed according to demands. Due to the specific shape of the voids, there are no issues with internal pressure.[18][19][20] Actual fire tests on slabs made the specific BubbleDeck geometry has been carried out in Europe, Asia and South America.

Sound

Tests have been carried out in Germany,[21] UK[22] and the Netherlands[23] according to ISO 140-4:1998, ISO 140-7:1998, ISO 717-1:1997 and ISO 717-2:1997 measuring impact and airborne sound. These tests show that 230 mm and thicker BubbleDeck® slabs can meet the national rules.

Qualities

- Low weight/stiffness ratio – influence of impact is proportional to weight.

- Simplicity and symmetry and uniform extent – Lessen the impact effect. Uniform and continuous distribution/flow of forces,

- Monolithic, continuous and ductile structure.

The BubbleDeck system fulfil these principles:

- Saves 35% weight compared to a corresponding solid slab – equal stiffness.

- Simple, monolithic behaviour, uniform and continuous distribution of forces.

- Max ductile structure - increased ductility due to increased strength/weight ratio.

Approvals

- Dutch Standards: From November 2001, The BubbleDeck system is incorporated in the Dutch Standards (by CUR – Civieltechnisch Centrum Uitvoering Research en Regelgeving).

- UK Standards: The BubbleDeck system can be treated as a normal flat slab supported on columns (BS 8110) according to CRIC (Concrete Research & Innovation Centre under the Imperial College of Science, Technology & Medicine), 1997.

- Danish Standards: The BubbleDeck system can be calculated from recognized principles and within existing standards - Directorate of Building and Housing, Municipality of Copenhagen, 1996.

- German Standards: The BubbleDeck system can be used according to existing technical standards according to Deutsches Institut für Bautechnik, 1994.

Advantages

Comparisons

A two way spanning voided biaxial slab construction compared to a traditional two way spanning non voided biaxial slab construction:

- The reduced weight of the slab will typical result in a change in design to longer spans and/or reduced deck thickness. The overall concrete consumption can be reduced with up to 50% depending on design, as a consequence of reduced mass in slabs, vertical structure and foundation.

A two way spanning biaxial slab construction compared to a one way spanning deck (traditionally a hollow core):

- One way spanning decks are supported by a combination of walls and beams. This leads to rigid and inflexible structures. This type of structure should be used with care in seismic regions due to the risk of progressive collapse.[24][25]

As this floor type is made of complete prefab elements with no structural coherence, support moments are absent, resulting in increased material consumption.

A two way spanning voided biaxial slab construction with spheres according to the BubbleDeck system, compared to older voided slab constructions:

- Acts like a solid slab. Does not have the earlier problems with reduced resistances towards shear, local punching and fire.

In general

Benefits include:

- Design freedom – flexible layout easily adapts to irregular & curved plan layouts.

- Reduced dead weight -35% removed allowing smaller foundation sizes.

- Longer spans between columns – up to 50% further than traditional structures.

- Downstand beams eliminated – quicker and cheaper erection of walls and services.

- Load bearing walls eliminated – facilitating MMC with lightweight building envelopes.

- Reduced concrete usage – 1 kg recycled plastic replaces 100 kg of concrete.

- Environmentally green and sustainable – reduced energy & carbon emissions.

8% of global CO2 emissions are due to cement production. 1 tonne of cement:[26]

- Releases 1 tonne of CO2

- Consumes 5 million BTU of energy

- Uses 2 tonnes of raw materials

Due to the BubbleDeck technology's green credentials, the use of the BubbleDeck system qualifies for LEED points in North America.[27][28]

LIGHT - THIN - BIDIRECTIONAL Reduction of weight up to 40%. Reduced deformations (maximum loss of stiffness- 15%). Reduction of the foundation load. Reduction of columns section or their number.

ECONOMIC Lower concrete cost with an equal thickness. Lower steel cost. Savings in useful height on each level as there are no emerging beams. Possibility to gain floors at the same building height (towers) and building volume. Quick and easy to implement. Also indicated for the top-down technique. Possibility of large span at equal load or high load bearing capacity at an equal span. Economical and easy to transport, handle and store, also outdoors. The soffit has a flat surface that is ready to finish and does not require a false ceiling for aesthetic purposes. If a false ceiling, is required it can be created faster.

FLEXIBLE Span up to 20 m. No beams between pillars. Reduction in the number of pillars. Can be used together with prefabs. Does not require handling and/or hoisting equipment. Possibility of single direction structures thanks to the bridge accessory.

EARTHQUAKE PROOF Lower seismic mass. Fewer dimensional limitations for the elements. Double slab, upper and lower.

OPEN SPACES Larger spaces. Greater architectural freedom. Simplified changes to the purpose of use.

FIRE RESISTANT Considerable fire resistance certified REI 180 with a concrete cover of only 3 cm.

IMPROVED ACOUSTIC BEHAVIOUR Thanks to the increased stiffness of the lower and upper slabs, acoustic transmittancy is decreased.

Thermal heating/cooling in slabs can substantial reduce the energy consumption.[29][30][31][32][33][34]

Implementation

Execution of prefabricated version

The overall floor area can be divided down into a series of planned individual elements, up to 3 m wide dependent upon site access, which are manufactured off-site using MMC techniques. These elements comprise the top and bottom reinforcement mesh, sized to suit the specific project, joined together with vertical lattice girders with the void formers trapped between the top and bottom mesh reinforcement to fix their optimum position. This is termed a ‘bubble-reinforcement’ sandwich, which is then cast into bottom layer of 60 mm pre-cast concrete, encasing the bottom mesh reinforcement, to provide permanent formwork within part of the overall finished slab depth.

On site the individual elements are then ‘stitched’ together with loose reinforcement simply laid centrally across the joints between elements. The splice bars are inserted loose above the pre-cast concrete layer between the bubbles, and purpose made mesh sheets tied across the top reinforcement mesh to join the elements together. After the site finishing, concrete is poured and cured. This technique provides structural continuity across the entire floor slab – the joints between elements are then redundant without any structural effect – to create a seamless biaxial floor slab.

Installation of pure in situ versions [35]

- The entire surface of the slab to be cast on site is shuttered with wood deckings (or similar systems), then the lower reinforconcrete bars are positioned in two mutually perpendicular directions according to the design and the lattice for the upper reinforconcrete is arranged.

- The voided biaxial slabs formworks are positioned using the lateral spacers joints to place them at the desired centre distance that will determine the beam width. Thanks to the conic elevator foot, the formworks will be lifted from the surface, making it possible for the lower slab to be formed. If double or triple elements are used, these elements must first be assembled, which will be supplied on distinct pallets in the yard.

- The positioning of the reinforconcretes is completed by placing above the formwork the upper bars in the two directions as well as the reinforcement for shear and punching where necessary, according to the design.

- The concrete casting must be performed in two phases to prevent the floatation of the formworks: an initial layer will be cast to fill a thickness equal to the height of the elevator foot. Casting will continue for this first portion of the slab until the concrete starts to set and become semi fluid.

- Once suitably set, the casting can be restarted from the starting point, completely burying the voided biaxial system. The casting is then levelled and smoothed in a traditional manner.

- Once the structure has hardened, the formwork can be removed. The surface is smooth in correspondence of the soffit.

Examples

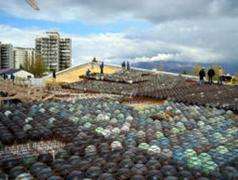

Below are some examples of the voided biaxial slabs being used y:

University, Utrecht in the Netherlands':

Vogaskoli, School in Reykjavik, Iceland:

Sogn Arena, Oslo in Norway:

City Hall and Offices, Glostrup in Denmark:

Some examples:

City Life Milano Italy

Architectural planner: Arata Isozaki & Associates, Zaha Hadid Architects, Studio Daniel Libeskind

ITC Lab (Leed Platinum) Italy

Architectural planner: Richard Meier & Partners Architects Master plan: Jean Nouvel Ateliers

Vulcano Buono Italy

Architectural planner: Renzo Piano Building Workshop

Beirut Terraces Lebanon

Architectural planner: Herzog de Meuron

See also

- Concrete

- Reinforced concrete

- Building construction

- Construction engineering

- Structural engineering

- Filigree concrete

- Rebar

References

- ↑ BubbleDeck.com

- ↑ Martina Schnellenbach-Held, StefanEhmann, Karsten Pfeffer: “BubbleDeck - New Ways in Concrete Building”. Technische Universität Darmstadt, DACON Volume 13, 1998

- ↑ Martina Schnellenbach-Held, Karsten Pfeffer: “BubbleDeck Design of Biaxial Hollow Slabs”. Technische Universität Darmstadt, DACON Volume 14, 1999

- ↑ BubbleDeck Report from A+U Research Institute /Professor Kleinmann - the Eindhoven University of Technology / the Netherlands, 1999

- ↑ BubbleDeck Test Report by Koning & Bienfait b.v. / The Netherlands, 1998

- ↑ Report of BubbleDeck from Technische Universitaet in Cottbus

- ↑ Report from the Eindhoven University of Technology / the Netherlands: ” Broad comparison of concrete floor systems”. December 1997

- ↑ BubbleDeck Report from Technical University of Denmark, 2003

- ↑ Report from Adviesbureau Peutz & Associes b.v.: ”Comparison of BubbleDeck vs. Hollow core”. Netherlands, 1997

- ↑ "Optimising of Concrete Constructions"; - The Engineering School in Horsens / Denmark, 2000

- ↑ BubbleDeck.nl : CUR-aanbeveling 86-01

- ↑ Martina Schnellenbach-Held, Heiko Denk: “BubbleDeck Time-Dependent Behaviour, Local Punching Additional Experimental Tests”. Technische Universität Darmstadt, DACON Volume 14, 1999

- ↑ Schnellenbach-Held, M., Pfeffer, K.: “Tragverhalten zweiachsiger Hohlkörperdecken, Beton- und Stahlbetonbau” 96 [9], 573-578 (2001)

- ↑ Pfeffer, K.: “Untersuchung zum Biege- und Durchstanztragverhalten von zweiachsigen Hohlkörperdecken”. Fortschritt-Berichte VDI, VDI-Verlag, Düsseldorf 2002

- ↑ "Punching Shear Strength of BubbleDeck" - The Technical University of Denmark, 2002

- ↑ BubbleDeck Test report from University of Darmstadt by Markus Aldejohann, Martina Schnellenbach-Held, 2003

- ↑ BubbleDeck Report from AEC Consulting Engineers Ltd. / Professor M.P. Nielsen - The Technical University of Denmark, 1993

- ↑ BubbleDeck Test report from University of Darmstadt by Markus Aldejohann and Martina Schnellenbach-Held, 2002

- ↑ TNO-Report on BubbleDeck for the Weena Tower / Rotterdam / the Netherlands, 1997

- ↑ TNO-Report for 230 mm BubbleDeck: ”Fire-safe in 120 minutes” the Netherlands, 1999

- ↑ German Test Certificate Number P-SAC 02/IV-065 according to DIN 4102-2 concerning BubbleDeck® slabs, 2001

- ↑ BubbleDeck Test Report from Ian Sharland Ltd Airborne and Impact Sound Insulation”.November 2005

- ↑ BubbleDeck Test Report from Adviesbureau Peutz & Associes b.v.: ”Sound Resistance”.March 2004

- ↑ Report on building systems in relation to seismic behaviour

- ↑ "Investigation of seismic behaviour of hollow-core slabs by various methods" by Dr. M.R. Adlparvar et al., Azad University Tehran South Unit

- ↑ Report from American Society of Civil Engineers: "Structural engineers, sustainability and LEED", p. 33, by Diana Klein

- ↑ Read, Jones and Christoffersen: BubbleDeck LEED points in North America

- ↑ Report from American Society of Civil Engineers: "Structural engineers, sustainability and LEED", p. 39 by Diana Klein

- ↑ Reports from European Concrete Platform: "Concrete for energy-efficient buildings - The benefits of thermal mass"

- ↑ "Cooling and heating of buildings by activating their thermal mass with embedded hydronic pipe systems" by Bjarne W. Olesen, Ph.D. and D. F. Liedelt, Technical University of Denmark

- ↑ Article from Concretethinkerz: "Radiant Floors"

- ↑ "Radiant heating and cooling by embedded water-based systems" by Bjarne W. Olesen, PH.D., Technical University of Denmark

- ↑ "Thermal advantages of concret - a European study" by Jesper Sand Damtoft, Report from Teknologisk Institut

- ↑ "Heating and cooling with thermoactive hydronic elements" Report from COWI, 2006

- ↑ (Italian) Soluzioni innovative per l'edilizia -