Triumph TR7 Sprint

| Triumph TR7 Sprint | |

|---|---|

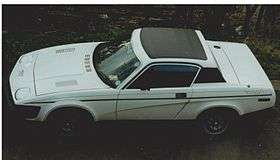

Figure 1: TR7 Sprint | |

| Overview | |

| Manufacturer | Triumph Motor Company |

| Production |

1977 59–62[1][2] |

| Assembly | Speke, Liverpool, England |

| Designer | Harris Mann, Spen King |

| Body and chassis | |

| Class | Sports car |

| Body style | 2-door coupé |

| Layout | FR layout |

| Related | Triumph TR7 |

| Powertrain | |

| Engine | 1,998 cc (2.0 l) 16-valve Slant-4 |

| Transmission | 5-speed manual |

| Dimensions | |

| Wheelbase | 85 in (2,159.0 mm) |

| Length | 160 in (4,064.0 mm) |

| Width | 62 in (1,574.8 mm) |

| Height | 50 in (1,270.0 mm) |

| Curb weight | 1,083 kg (2,387.6 lb) |

The Triumph TR7 Sprint was a version of the Triumph TR7 sports car from the Triumph Motor Company (part of British Leyland) produced in 1977 in very limited numbers: probably no more than 62 in total. It used the 127 bhp, 16-valve, 2-litre version of the Triumph slant-four engine from the Triumph Dolomite Sprint, instead of the TR7 base model's 105 bhp, 8-valve, 2-litre version.[1][3] However, the 16-valve version was originally specified in the Dolomite Sprint at 135 bhp, and carefully assembled, standard engines had been known to give a sustained 150 bhp on the factory test bed.[4][5][note 1] A highly tuned version of the 16-valve engine "rated at 225 bhp at 8000 rpm" by 1977 was also used in the Group 4 TR7 cars of the BL works rally team, from 1976 until 1978.[6]

The reason why there were so few TR7 Sprints is unclear, since the two engines used the same block, etc., and it seemed an obvious development. It has been suggested that BL intended to produce the TR7 Sprint, but cancelled it; though as the model was never officially announced by BL, neither was its cancellation announced or explained. The possible reasons that have been suggested are that it was cancelled as a result of industrial action at the Speke plant where the TR7s were being made - which caused TR7 production to be moved to the BL plant at Canley -, it was cancelled by sales and marketing for not being a sufficient improvement over the TR7 base model, or because it could not meet emissions legislation requirements for the US market - at which the TR7 and later TR8 were primarily aimed.[1][3][7][8]

Technical specification

Engine: Triumph Slant Four 1,998cc 16 valve

Capacity: 1998 cc

Valves: 16

Compression ratio: 9.5:1[9]

Fuel system: Twin 1¾" choke SU HS6 carburettors[9]

Maximum Power: 127 bhp @ 5200 rpm (estimated)[9][note 1]

Maximum Torque: 122 lb ft @ 4500 rpm (estimated)[9][note 1]

Performance Data

0–60 mph: 8.5 seconds (estimated)[9]

Max speed: 120 mph (estimated)[9]

The improvements in the 0–60 time and top speed over the TR7's 9.6 seconds and 111 mph are not huge.[10] However, the figures for the 16 valve version of the TR7 are almost identical to those for the US specification carburettor version of the 3.5 litre 135 bhp Rover V8 powered Triumph TR8,[1] which are 120 mph and 8.4 seconds.[11] Also, one of the then Triumph engine development engineers is quoted as saying "The real test was the 30–50, 50–70 [mph] times and here the Sprint was significantly superior to the 2V [2 valves per cylinder] engine and even challenged the TR8's abilities. Certainly, if we were going 'off site' the preferred vehicle to 'borrow' was a Sprint TR7 over all others and that includes the TR8."[3]

Also, despite being specified at 127 bhp, Spen King related "how he went away on holiday and came back to find an engine running on the bed giving 150 bhp at the first build."[5] This would be very close to the 153 PS DIN (±5%)[12] that was given by the Rover V8 engine in the UK Specification TR8.[1] Hence, it is possible that had Triumph produced the TR7 Sprint and TR8 to UK specification, as was apparently planned at one time,[3][8] there would have been significant debate of their relative merits, some of it probably rather partisan in nature.

Production details

According to the BMIHT archives, there are production records for chassis numbers ACH/4 to ACH/25, and ACH/00501 to ACH/00536 and ACH/00700: 59 cars.[2][note 2] Also, ACH 1 is identified by the TR Drivers Club, as UK registration WAC 274S, and that ACH 2 and ACH 3 existed might have been inferred from this: "One [unattributed] source states that there were three batches of Sprints, ACH 1 to ACH 25, ACH 501 to ACH 536 and ACH 700 on its own, a total of 62 vehicles."[1] What production records there are at the BMIHT do not provide registration details from which cars might be traced; however, some further details of the cars known to have been produced are provided by the TR Drivers Club.()

While it is widely held that the factory TR7 Sprints were built at Speke, a Triumph engine development engineer is quoted as saying "Some if not all of these cars were definitely converted at Canley from 8-valve to 16-valve". The reason given for this is that "the Speke unions wanted added bonuses for dealing with 'non-standard' cars."[3] However, another Triumph employee, responsible for engineering liaison between Speke and Canley, is quoted as saying that "At the changeover in July 1977 (to the new common underframe) we built a batch of thirty TR7 Sprints."[3]

The TR Drivers Club website gives details for only two of the first group of 25 chassis numbers: what was presumably the first prototype, WAC 274S, and one other, WAC 253S. It is suggested that most of the other cars in this batch were LHD and sold abroad.[1] Both known cars from this group were registered in Coventry in September 1977.[13]

The first two cars of the second group of chassis numbers were both white, and registered in Coventry as VVC 696S and VVC 697S in August 1977.[13] These were, according to an owner written article in the TR Driver's Club Magazine from 1991,() used for reliability testing. While there are no reliable details for BL's use of these actual cars, according to one source the procedure used with the TR7 and TR8 was to run a test car on the Belgian pavé track at MIRA for 1000 miles, "effectively providing wear harder than a vehicle might experience in a lifetime of normal use". The same source also states that "A related assessment exercise for the TR7 was the '90 day corrosion test', for which a prototype was built without the usual zinc primer or anti-corrosion treatments and the body painted white, the best colour to show up any rust streaks." A Triumph engineer is quoted as saying, "this prototype was run around a variety of road surfaces under wet conditions and then the damp areas were checked. The vehicle was then fitted with a series of nozzles which sprayed salt solution into these same areas".[14]

Thirty cars from this second group of chassis numbers were sequentially registered SJW 521S to SJW 550S (see Figure 4) in Birmingham in three groups in November 1977,[13] and went to the BL press garage at the Canley site, Coventry; presumably for publicity purposes.[15] It is claimed that these press garage cars were stripped and re-trimmed, and possibly also re-sprayed.[3]

Another car of this second group of chassis numbers was registered in Coventry as ARW 181S in July 1978.[13] According to a letter from the then archivist, reporting the research of the BMIHT records, "This car was originally intended for display at the 1977 [ Daily Express ] Motorfair in Earls Court, London. We can not verify whether it was in fact displayed here."[16]

It seems that nothing at all is known about the last car built in October 1977, ACH/00700, beyond what is given in its production record in the BMIHT archives.

The addition of two leading zeros to this second group of chassis numbers to make them five digits,[note 2] the same length as production TR7's chassis numbers, may indicate these were pre-production cars, not prototypes. However, the differences in where and by which division of BL they were registered (from their (V55) registration documents), indicates that they may still not have been manufactured as a single batch. Hence, it is possible that the press garage (SJW) cars were the "batch of thirty TR7 Sprints" built at "the changeover in July 1977", and the cars in the first group, and possibly some of the second, may have been those built as 8-valve cars at Speke, and converted to 16-valve at Canley.

However, the test cars, VVC 696S and 697S, cannot have been built at Speke as 8-valve cars and converted to 16-valve specification at Canley. This is because they were 1978 year model cars, yet their production dates in May–June 77, from the BMIHT archive,[2] predate the July 77 changeover to the production of the 1978 year model at Speke. Hence it is probable that these were built as 16-valve cars from scratch, possibly at Canley, using '78 year model body shells, e.g. from the '78 year model's development process. That they may have been built at Canley is suggested by their Coventry registrations, and may be even more likely if they were finished differently, i.e. without rust protection, as were the TR7 and TR8 test cars.

Distinguishing features

"There are a [comparatively] large number of privately built Sprint conversions about... Buyers should beware of this if they are asked a premium price for an alleged 'genuine' TR7 Sprint":[1] all the essential parts to turn a TR7 into a functional copy of a TR7 Sprint, though not an identical one, can either be sourced from a Dolomite Sprint or remain available from suppliers; several companies sell conversion kits online; and several sources provide information and advice on this TR7 Sprint conversion.[17][18] One of which states, "this upgrade brings you into the same power band as an original TR8, but for a fraction of the cost, effort and time."[17] There are also a number of websites dedicated to the Sprint and Sprint conversions, () and at least one forum.

It seems that there is no disagreement that "[a]ll [factory TR7 Sprint] cars were fixed-head coupes",[1] that the period over which they were built spans the changeover between the 1977 and 1978 year models,[note 3] and both right and left hand drive cars were produced.[1][3] Those TR7 Sprints that are known were fitted with the 5-speed gearbox mated to the 3.89:1 rear axle that was standard on the 5-speed TR7s. The pre-production cars had the alloy wheels that were optional for later TR7s and standard on Solihull built fixed-heads.[19]

Engine and interior

The factory produced TR7 Sprints have chassis numbers that are prefixed with letters ACH; whereas, UK/Australian/European specification TR7s of the time were prefixed ACG:[1][3] Figure 5 shows a chassis or commissioning plate from a TR7 Sprint car, mounted on the left-hand door, below the door lock. The TR7 Sprint engines are also prefixed with CH, rather than GC on the TR7's and VA on Dolomite Sprint engines; however, the TR7 Sprint engine numbers can, at least in some cases, be very hard to read (see Figure 6).

There are a number of auxiliary engine parts specific to the TR7 Sprint, and not used on the Dolomite Sprint engine: the cast steel exhaust manifold (RKC2788),[1] the front pipe of the exhaust system (which has been remanufactured, RB7385), and a water transfer plate at the back of the cylinder head (also remanufactured, RB7240).

A number of parts in the throttle linkage are also unique to the TR7 Sprint, most obviously the link plate between the two carburettors (just visible in Figure 2, and partially obscuring the inlet manifold in Figure 3), which was not fitted to the Dolomite Sprint; and the throttle lever/link rod (visible just over the air box in Figure 3), which looks the same as the TR7 part, but is longer to allow for the carbs being further apart.

The front disks were specific to the TR7 Sprint, although the callipers and dust shields, etc., were as those used on the TR8;[1] so TR8 disks fit.

There are also at least two different Engine information panels (UKC 8605 and TKC 5228), on the underside of the bonnet, some of which only indicate TR7, but provide slightly different information to that on the equivalent TR7 part (UKC 6246).

There are online photographs of some of these parts.()

At least some of the cars were fitted with the large semi-circular pad on the steering wheel from the US specification TR7 (RKC82) (see Figure 7).

There is one unsupported claim that "Having a higher-revving engine, the Sprint received a recalibrated rev counter".[1] However, this is incorrect: both engines had a rev limit of 6500 r.p.m. indicated on the rev counter, though both owners' manuals give the "Maximum recommended engine speed (intermittent)" as 6,000 r.p.m.[20][21] Hence, the TR7 and TR7 Sprint shared a common rev counter.

Exterior

It appears that the exterior of the pre-production TR7 Sprints was, and presumably the production cars would have been, indistinguishable from the TR7 of the day, apart from the decals and side stripes. However, it is reported that a number of different decal sets were being tried out on the prototype cars.[1][3]

There are a number of published photographs of TR7 Sprints bearing decals simply comprising the word "SPRINT" on the front panel and boot lid below the 'TR7' decal of Speke built TR7s,[1][3][22] and described as "The logo that appeared on the boot lid of most of the few TR7 Sprints that escaped from the factory."[1] These used the same font as the TR7 decal applied to Speke built TR7s and in the side stripes used later on the TR7 Premium edition. There is also a description of a car "with the word 'Sprint' written large on the right of the boot lid, the TR7 decal being on the left".[1] These decals were at one time available (in three sizes) from Moss Europe (previously TriumphTune), though they were not catalogue items or identified to a BL part number or numbers.[23] One size is still available as supplier part No. RB7206BLACK/SILVER/GOLD.

There is also a published photograph of what appears to be a US Spec., 1977 year model car carrying side stripes with the word "Sprint" on the rear wings, the caption to which states "The sides of the TR7 Sprint were supposed to have received this striping treatment, designed by John Ashford, had the car gone into production."[3] These side stripes were, at one time, listed by Moss Europe under BL part numbers YKC2082-2087.[23] They are also shown in contemporary pictures of an original TR7 Sprint from the press garage, which are available from the British Motor Industry Heritage Trust (BMIHT).[24][25] The car in these photographs from the BMIHT does not carry the "SPRINT" decals, described above, on either boot lid or front panel. The TR7 Sprint shown in figures 1 and 8 is, in this respect, identical with these photographs, except for the colours. The stripes themselves were later reworked for the TR7 Premium edition after the TR7 Sprint was still born.[3]

Publications

The BL TR7 Repair Operations Manual, AKM3079A, covers both the 4 and 2 valve (per cylinder) engines; however, an erratum stuck to the title page states "At the time of going to press the 4 valve engine referred to in this manual has not been fitted to the Triumph TR7".[26]

An owner's handbook, AKM 3967, was also produced for TR7 Sprint in 1977, but is apparently for the 1977 year model: it shows the interior light in the headlining not the doors. Also some of the information is incorrect for the TR7 Sprint, i.e. pictures show the 8 valve engine and the TR7's AC Delco distributor. However, it also lists only the 5 speed (LT77) gearbox, unlike the similar handbook for the TR7, RTC 9210, which lists the 4 speed, and the 5 speed as an option.[20]

Use in competition

The TR7s used by BL in Group 4 rallying, from their advent in the Welsh rally of 1976 to the Circuit of Ireland in 1978, also used (tuned) 16-valve 2 litre Sprint engines, which by 1977 was rated at "rated at 225 bhp at 8000 rpm".[6] These 16-valve TR7 rally cars proved competitive on asphalt, winning a number of events including the Belgian Boucles de Spa rally in 1977.[6] They were replaced by the Rover V8 3.5 litre engined TR7V8.[note 4]

There is some confusion over exactly how the TR7 was homologated (for group 4) with the 16 valve engine, close ratio sprint gearbox and overdrive, and heavy duty rear axle before any TR7 Sprints were produced.[27] Rally journalist and historian Graham Robson refers to the "famous 'inventive homologation' skills" of Bill Price, then BL Competitions Dept. Manager, and to him "perhaps, taking lessons from Ralph Broad, who was an old hand at the black art of 'reading the rules'", and states that "Bill [Price] managed to gain approval for a TR7 which was only loosely related to the production car." Bill Price himself wrote on this issue "Careful consideration was given to the existing specification with the result that we decided to list the 16-valve Sprint cylinder head to enable us to virtually transplant the Sprint rally engine into the car. The Sprint gearbox was homologated as the 77mm five-speed [LT77] gearbox was not yet available and it would take time to produce close ratio gears for it. The heavy duty axle which would be standard with the five-speed gearbox was also listed [for Group 3] as an [export] option".[27] However, Graham Robson quotes BL Motorsport director John Davenport remembering "that the '100-off' rule applied to alternative engines at the time (which explains why Ford was able to race 24-valve four-cam Capris in 1974), but this waiver never applied to transmissions."[6]

The 100-off rule was a section of the FIA's rules for homologating Group 4 cars (actually, for homologating Group 2 cars, but also applicable to Group 4). It covered a list of "Optional equipment which may be recognized with a minimum production of 100 units per year to equip 100 cars". While John Davenport was correct that, in 1975, this list included alternative cylinder heads with different numbers of valves, it also did include alternative gearboxes with overdrives, flywheels, clutches and their housing, and many other engine, transmission, and suspension components. Such optional equipment could be recognized as "bolt-on option kits", which had to be "available freely at the manufacturer's or his dealers' for any one wishing to purchase it" - as would have been the case with the 16-valve head and its drive (pistons, carbs, and manifolds could be changed freely for Group 4), and for the overdriven gearbox, as spare parts for the Dolomite Sprint (the heavy duty axle was homologated for Group 3, and thus 4, by a different means). But when the 16-valve TR7 was homologated for Group 4 in October 1975, the 100-off rule did not require the production of any 16-valve engined road cars, only the kits needed to equip them.[28][29]

However, the 100-off rule also required that the kits could be fitted "without it being necessary to machine or modify the remaining mechanical parts" and therefore "it must be possible to reassemble the whole unit with all its original parts", and they "must be mentioned in the manufacturer's catalogue of spare parts for the model concerned". While it should have been possible to return a Group 4 car to Group 3 specification, some modifications to the under-body may have remained, and while the FIA rules failed to precisely define the catalogue or its level of distribution, the 16-valve head and overdriven gearbox were not listed in the generally available TR7 parts catalogue. Hence, it might be argued that BL did not comply exactly with the rule in these regards. Also, there is no obvious article in the homologation rules that covered the recognition of the heavy duty rear axle for Group 3 in 1975. This component was, however, recognized for Group 3 a second time, presumably after the production of sufficient 5-speed TR7s, in January 1977.

A number of other modifications were listed in the amendment (1/1V) to the TR7's homologation for the Group 4 TR7, such as larger front callipers and rear disk brakes. These were allowed from a list of "Optional equipment which may be recognized without a minimum production".[30] Other modifications that are not listed in the papers, such as suspension components and axle locating arms, etc., were given as freely allowed to be changed or added without need of being specifically recognized as part of the homologation process.[31]

Four of the later BL works rally cars bear the registrations of cars from the press garage, SJW 533S, SJW 540S, SJW 546S, and SJW 548S. SJW 533S was initially campaigned as a 4 cylinder 16 valve car, and later as a V8 3.5 Litre TR7V8 specification. The other three were only ever campaigned as TR7V8s. However, it is not clear whether or not the four rally cars bearing these registrations actually were, in any real sense, the TR7 Sprints from the press garage, or whether only the registrations were used. There is a story at one TR7 related website (), and already current in the 1980s, that John Davenport, "needed white cars without sunrooves [sic] and these were the nearest four." However, according to the press garage data (Figure 4), SJW 533S was russet, SJW 540S was java green, SJW 546S was brooklands green, and SJW 548S was carmine; though none had sun-roofs. While there are suggestions that the cars sent to the press garage were re-trimmed and even possibly re-sprayed,[3] there are no suggestions that their paint colours were changed, and the competitions department could, presumably, have managed that themselves, were it significant. Equally anecdotally, a more complete reproduction of the 1991 owner written article from the TR Driver's Club magazine states "Although the SJW TR7V8 rally cars began life as TR7 Sprints, the rally cars were scratch built using bodies taken off the line and prepared by Safety Devices. So only the registration numbers from the sprints were used."()

Cancellation

There had been significant speculation regarding the possible production of a 16-valve version of the TR7 from the outset. This was because the TR7 engine was, basically, the block from the 16-valve Dolomite Sprint engine mated to a modified version of the Dolomite 1850's 8-valve cylinder head.[note 5] So a 16-valve version seemed an obvious development.[1][3] However, the TR7 Sprint was never formally announced; hence, neither was its cancelation.

The usual reason given for the cancellation of the TR7 Sprint is the 17-week-long strike at the BL Speke plant in 1977-8, where the TR7 and at least some of the TR7 Sprints were manufactured. This resulted in the closure of the plant in May 1978, the move of production to Canley, Coventry, and led to the cancellation of the TR7 Sprint.[1][3] However, this is itself blamed, ultimately, on the "replacement of the aristocratic Lord Stokes with South African businessman Michael Edwardes" as managing director in 1977.[7]

Another reason given is that the BL marketing department caused the cancellation because the 0–60 time and top speed was not sufficiently different from the TR7's. While this lack of significant difference is disputed, it is the case that, unlike the TR7 and TR8, the Sprint's 16 valve engine was not suitable for the vehicle emissions control equipment needed for the US market, which was the main target market for the TR7 and 8.[3] Hence the marketing department may have seen a higher specification version of the TR7 that could not be sold in the US as a threat to TR7 sales there.

When the TR7 Sprint programme was cancelled, and the cars became redundant, "most were sold off to private buyers"[1] and some went into BL's management car plan and were leased to BL employees, and a number are known to still exist.[1][3]

See also

Notes

- 1 2 3 The power and torque figures given are for the 16 valve, 2 litre, slant four engine in a Dolomite Sprint. The TR7 Sprint had a different exhaust manifold - as the Dolomite one interfered with the bulkhead -, which may have been less restrictive and given more power/torque.

- 1 2 This chassis number format is taken from BMIHT Production Record Trace Certificate Number 90/5959 for VVC 697S, dated 25th April 1990, which indicates it as being "RHD, Home Market" Specification. The leading zeros are also visible on the chassis plate shown in Figure 5 and on one shown at '5'.

- ↑ The significant differences between 1977 and 1978 year model cars are in the sizes of the filler cap, the 1977 year model having a very large one and the 1978 model having a smaller one; and in the positioning of the interior lights, the 1977 having a light in the headlining and a map light behind and between the seats, and the 1978 having rocking-switch lights in both doors. These modifications were necessary for the TR7 convertible, which was also in design/prototype/pre-production in 1977-8.

- ↑ According to Graham Robson, "by April 1978 [when it was homologated] the TR8 had not been launched, so as a compromise to keep BL marketing people happy, it was called TR7V8 instead."

- ↑ With a slightly larger combustion chamber.

References

- 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 Piggott B., Clay S., Collector's Originality Guide Triumph TR2 TR3 TR4 TR5 TR6 TR7 TR8, page 312-5, 2009, MotorBooks International Company, ISBN 9780760335765.

- 1 2 3 British Motor Industries Heritage Trust Archives, Heritage Motor Centre, Gaydon, Warwickshire, England: accessed June 2013.

- 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 Knowles D., Triumph TR7 The Untold Story, 2007, pages 110–5, Crowood Press, ISBN 978-1-86126-891-4.

- ↑ Classic Motor Monthly Archives, The Triumph Dolomite Sprint, Retrieved 13 April 2009.

- 1 2 "Triumph Dolomite Sprint", Auto Car, 21 June 1973, Vol 138 No 4021, pages 36-40

- 1 2 3 4 Robson G., The Works Triumphs: 50 Years in Motorsport, 1993, J H Haynes & Co Ltd, ISBN 978-0854299263.

- 1 2 Marren, Brian (2009). "Closure of the Triumph TR7 Factory in Speke, Merseyside, 1978: 'The Shape of Things to Come'?". Retrieved 16 July 2010.

- 1 2 Robson G., Langworth R., Triumph Cars : The Complete Story, 2005, Motor Racing Publications, Limited, ISBN 9781899870721.

- 1 2 3 4 5 6 Retrocaricons, Triumph TR7 Sprint Retrieved 3 January 2013

- ↑ Retrocaricons, Triumph TR7 Retrieved 16 December 2014

- ↑ Classic and Performance Car, , Retrieved 13 September 2013

- ↑ Department of Transport Type Approval No. 377

- 1 2 3 4

- ↑ Knowles D., Triumph TR7 The Untold Story, 2007, page 51, Crowood Press, ISBN 978-1-86126-891-4.

- ↑ Thoroughbred & Classic Cars, January 1979 edition

- ↑ Clausager, A. D. (BMIHT Archivist), untitled letter detailing BMIHT records research on ARW 181S, ref "PRI Triumph", dated 24 February 1989.

- 1 2 Williams R., How to Improve Triumph TR7, TR7-V8, TR8; 2007, Veloce, ISBN 9781845840457

- ↑ Moss Europe LTD, MOSS Performance Manual, MGL 9800, no date given

- ↑ Bill Piggott, Original Triumph TR7 & TR8, Motorbooks International, ISBN 978-0760309728, 2000, page 61.

- 1 2 Leyland Cars, Triumph TR7 Sprint Handbook, Leyland International, Publication Part No AKM 3967.

- ↑ British Leyland UK Ltd., Triumph TR7 Handbook, Publication Part No RTC 9210.

- ↑ Hardcastle D., The Rover V8 Engine, J H Haynes & Co Ltd; 2nd Revised edition (15 May 1995), ISBN 978-0854299614.

- 1 2 Moss Europe LTD, MOSS Parts Catalogue, MGL 6900, September 1993

- ↑ BMIHT Picture ref. T-105516

- ↑ BMIHT Picture ref. T-105514

- ↑ British Leyland, Triumph TR7 Repair Operation Manual, 1978, Leyland Cars, Publication Part No AKM 3079A.

- 1 2 Bill Price, B.M.C./B.L. Competitions Department: 25 Years in Motorsport - The Cars, the People, the Events, 1989, J H Haynes & Co Ltd, ISBN 978-1859604397.

- ↑ FIA, Appendix J to the International Sporting Code 1975: Classification, definition and specifications of cars, January 27, 1975, Article 260, clause z, sub-clause bb.

- ↑ RAC TR7 Homologation papers number 3071.

- ↑ FIA, Appendix J to the International Sporting Code 1975: Classification, definition and specifications of cars, January 27, 1975, Article 260, clause z, sub-clause cc.

- ↑ FIA, Appendix J to the International Sporting Code 1975: Classification, definition and specifications of cars, January 27, 1975, Article 260, "clauses c to y.

External links

- TriumphTR7.co TR7 Sprint Conversion Page

- Mike Jeffreys' TR7 Sprint Conversion Page

- Copy of owner written TR Drivers Club article TR7 Sprint Conversion from 1991 issue 2

- Club Triumph TR7-8 Forum thread covering TR7 Sprint Alt. Water Transfer Plate

- Yorkshire TR Drivers page on specific TR7 Sprint parts

- TR Drivers Club List of known TR7 Sprints

- Copy of owner written TR Drivers Club article TR7 16 Valve Sprint from 1991 issue 2

- TR7 Sprint Internet forum

- TR7 & TR7 V8 Rally cars

- More complete reproduction of owner written TR Drivers Club article TR7 16 Valve Sprint from 1991 issue 2

- Club Triumph TR7-8 Forum thread covering TR7 Sprint sidestripes and decals