Tardiness (scheduling)

In scheduling, tardiness is a measure of a delay in executing certain operations and earliness is a measure of finishing operations before due time. The operations may depend on each other and on the availability of equipment to perform them.

Typical examples include job scheduling in manufacturing and data delivery scheduling in data processing networks.[1]

In manufacturing environment, inventory management considers both tardiness and earliness undesirable. Tardiness involves backlog issues such as customer compensation for delays and loss of goodwill. Earliness incurs expenses for storage of the manufactured items.[2]

Mathematical formulations

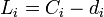

In an environment with multiple jobs, let the deadline be  and the completion time be

and the completion time be  of job

of job  . Then for job

. Then for job  lateness is

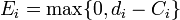

lateness is  , earliness is

, earliness is  , tardiness is

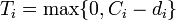

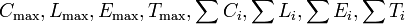

, tardiness is  . The common objective functions are

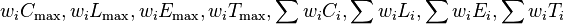

. The common objective functions are  or weighted version of these sums,

or weighted version of these sums,  , where every job comes with a weight

, where every job comes with a weight  . The weight is a representation of job cost, priority, etc.

. The weight is a representation of job cost, priority, etc.

In a large number of cases the problems of otimizing these functions are NP-hard.[3]

References

- ↑ Minimizing tardiness in data aggregation scheduling with due date consideration for single-hop wireless sensor networks, Wireless Networks, Volume 21 Issue 4, May 2015 Pages 1259-1273

- ↑ Derya Eren Akyol , G. Mirac Bayhan, Multi-machine earliness and tardiness scheduling problem: an interconnected neural network approach, The International Journal of Advanced Manufacturing Technology May 2008, Volume 37, Issue 5, pp 576-588

- ↑ "Complexity results for scheduling problems", University of Osnabrueck