Studebaker

|

Badge used in the 1950s and 1960s | |

| Industry | Vehicle manufacture |

|---|---|

| Founded | February 1852 |

| Founder | Studebaker brothers (pictured below) |

| Defunct | May 1967 |

| Headquarters | South Bend, Indiana, USA |

| Products |

Automobiles historic wagons, carriages and harness |

| Parent | Studebaker Brothers Manufacturing Company |

| Website |

www |

Studebaker (1852–1967 /ˈstjuːdəbeɪkər/ STEW-də-bay-kər) was an American wagon and automobile manufacturer based in South Bend, Indiana. Founded in 1852 and incorporated in 1868[1] under the name of the Studebaker Brothers Manufacturing Company, the company was originally a producer of wagons for farmers, miners, and the military.

Studebaker entered the automotive business in 1902 with electric vehicles and in 1904 with gasoline vehicles, all sold under the name "Studebaker Automobile Company". Until 1911, its automotive division operated in partnership with the Garford Company of Elyria, Ohio, and after 1909 with the E-M-F Company. The first gasoline automobiles to be fully manufactured by Studebaker were marketed in August 1912.[2]:p231 Over the next 50 years, the company established a reputation for quality and reliability.[3]

After years of financial problems, in 1954 the company merged with luxury carmaker Packard to form Studebaker-Packard Corporation. However, Studebaker's financial problems were worse than the Packard executives thought. The Packard marque was phased out, and the company returned to the Studebaker Corporation name in 1962. The South Bend plant ceased production on December 20, 1963, and the last Studebaker automobile rolled off the Hamilton, Ontario, Canada, assembly line on March 16, 1966.

History

19th-century wagonmaker

German forebears

According to the official Studebaker history written by Albert R. Erskine, History of the Studebaker Corporation, South Bend, Indiana, published in 1918, "The ancestors of the Studebaker family first arrived in America at the Port of Philadelphia on September 1, 1736, on the ship Harle, from Rotterdam, Holland, as shown by the original manuscripts now in the Pennsylvania State Library at Harrisburg, and included Peter Studebecker, age 38 years; Clement Studebecker, age 36 years; Henry Studebecker, age 28 years; Anna Margetha Studebecker, age 38 years; Anna Catherine Studebecker, age 28 years. The last part of the name, "becker," was afterwards changed to "baker." The tax list of what was then Huntington Township, York County, Pennsylvania, in 1798-9, showed among the taxable were Peter Studebaker, Sr., and Peter Studebaker, Jr., wagonmakers, which trade later became the foundation of the family fortune and the corporation which now bears the name.[4]:p.11

In Albert Russel Erskine's official history, John Studebaker, father of the five brothers, born in Adams County, Pennsylvania, was the son of Peter Studebaker.[4]:p.13 In any event, John Studebaker (1799–1877) moved to Ashland, Ohio in 1835[4]:p13 with his wife Rebecca (née Mohler) (1802–1887) and taught his five sons to make wagons. They all went into that business as it grew to gigantic proportions with the country.

The five brothers

The five sons were, in order of birth: Henry (1826–1895), Clement (1831–1901), John Mohler (1833–1917), Peter Everst (1836–1897) and Jacob Franklin (1844–1887). The boys had five sisters.[5] Photographs of the brothers and their parents are reproduced in the 1918 company history, which was written by Erskine after he became president, in memory of John M.,[4]:p.5 whose portrait appears on the front cover.

South Bend operation

Clement and Henry Studebaker, Jr., became blacksmiths and foundrymen in South Bend, Indiana, in February 1852.[2]:p229[6] They first made metal parts for freight wagons and later expanded into the manufacture of complete wagons. At this time, John M. was making wheelbarrows in Placerville, California. The site of his business is California Historic Landmark #142.[7]

The first major expansion in Henry and Clem's South Bend business came from their being in the right place to meet the needs of the California Gold Rush that began in 1849. From his wheelbarrow enterprise at Placerville, John M. had amassed $8,000. In April 1858, he quit and moved out to apply this to financing the vehicle manufacturing of H & C Studebaker, which was already booming because of a big order to build wagons for the US Army. In 1857, they had also built their first carriage—"Fancy, hand-worked iron trim, the kind of courting buggy any boy and girl would be proud to be seen in".[8]:p.24

That was when John M. bought out Henry's share of the business. Henry was deeply religious and had qualms about building military equipment. The Studebakers were Dunkard Brethren, conservative German Baptists,[9] a religion that viewed war as evil. Longstreet's official company history simply says "Henry was tired of the business. He wanted to farm. The risks of expanding were not for him".[8]:p.26 Expansion continued from manufacture of wagons for westward migration, as well as for farming and general transportation. During the height of westward migration and wagon train pioneering, half of the wagons used were Studebakers. They made about a quarter of them, and manufactured the metal fittings for other builders in Missouri for another quarter-century.

The fourth brother, Peter E, was running a successful general store in Goshen, Indiana which was expanded in 1860 to include a wagon distribution outlet.[8]:p.28 A major leap forward came from supplying wagons for the Union Army in the Civil War (1861–65). By 1868, annual sales had reached $350,000.[2]:p229 That year, the three older brothers formed the Studebaker Brothers Manufacturing Company—Clem (president), Peter (secretary), and John M. (treasurer).[8]:p.38 By this time, the factory had a spur line to the Lake Shore railroad and, with the Union Pacific Railroad finished, most wagons were now dispatched by rail and steamship.

World's largest vehicle house

In 1875, the youngest brother, 30-year-old Jacob, was brought into the company to take charge of the carriage factory, making sulkies and five-glass landaus. Following a great fire in 1874 which destroyed two-thirds of the entire works, they had rebuilt in solid brick, covering 20 acres (81,000 m2) and were now "The largest vehicle house in the world".[8]:p.43 Customers could choose from Studebaker sulkies, broughams, clarences, phaetons, runabouts, victorias, and tandems. For $20,000, a four-in-hand for up to a dozen passengers, with red wheels, gold-plated lamps and yellow trim, could be had.

In the 1880s, roads started to be surfaced with tar, gravel, and wooden blocks. In 1884, when times were hard, Jacob opened a carriage sales and service operation in a fine new Studebaker Building on Michigan Avenue, Chicago. The two granite columns at the main entrance, 3 feet 8 inches (1.12 m) in diameter and 12 feet 10 inches (3.91 m) high, were said to be the largest polished monolithic shafts in the country.[10] Three years later in 1887, Jacob died—the first death among the brothers.

In 1889, incoming President Harrison ordered a full set of Studebaker carriages and harnesses for the White House.[11] As the 20th century approached, the South Bend plant "covered nearly 100 acres (0.40 km2) with 20 big boilers, 16 dynamos, 16 large stationary engines, 1000 pulleys, 600 wood- and iron-working machines, 7 miles (11 km) of belting, dozens of steam pumps, and 500 arc and incandescent lamps making white light over all".[8]:p.54 The worldwide economic depression of 1893 caused a dramatic pause in sales and the plant closed down for five weeks, but industrial relations were good and the organized workforce declared faith in their employer.

The impressive wagons pulled by the Budweiser Clydesdales are Studebaker wagons modified to carry beer, originally manufactured circa 1900.[12]

Family association continues

The five brothers died between 1887 and 1917 (John Mohler was the last to die).[13] Their sons and sons-in-law remained active in the management, most notably lawyer Fred Fish after his marriage to John M's daughter Grace in 1891.[14] "Col. George M Studebaker, Clement Studebaker Jr, J M Studebaker Jr, and [Fred Sr's son] Frederick Studebaker Fish served apprenticeships in different departments and rose to important official positions, with membership on the board."[4]:p41 Erskine adds sons-in-law Nelson J Riley, Charles A Carlisle, H D Johnson, and William R Innis.

Studebaker automobiles 1897–1911

In the beginning

In 1895, John M. Studebaker's son-in-law Fred Fish urged for development of 'a practical horseless carriage'. When, on Peter Studebaker's death, Fish became chairman of the executive committee in 1897, the firm had an engineer working on a motor vehicle.[8]:p.66 At first, Studebaker opted for electric (battery-powered) over gasoline propulsion. While manufacturing its own Studebaker Electric vehicles from 1902 to 1911, the company entered into body-manufacturing and distribution agreements with two makers of gasoline-powered vehicles, Garford of Elyria, Ohio, and the Everitt-Metzger-Flanders (E-M-F) Company of Detroit and Walkerville, Ontario. Studebaker began making gasoline-engined cars in partnership with Garford in 1904.[15]

Garford

Under the agreement with Studebaker, Garford would receive completed chassis and drivetrains from Ohio and then mate them with Studebaker-built bodies, which were sold under the Studebaker-Garford brand name at premium prices. Eventually, vehicles with Garford-built engines began to carry the Studebaker name. Garford also built cars under its own name and, by 1907, attempted to increase production at the expense of Studebaker. Once the Studebakers discovered this, John Mohler Studebaker enforced a primacy clause, forcing Garford back on to the scheduled production quotas. The decision to drop the Garford was made and the final product rolled off the assembly line by 1911, leaving Garford alone until it was acquired by John North Willys in 1913.

E-M-F

Studebaker's agreement with the E-M-F Company, made in September 1908,[4]:p47 was a different relationship, one John Studebaker had hoped would give Studebaker a quality product without the entanglements found in the Garford relationship, but this was not to be. Under the terms of the agreement, E-M-F would manufacture vehicles and Studebaker would distribute them exclusively through its wagon dealers.

The E-M-F gasoline-powered cars proved disastrously unreliable, causing wags to say that E-M-F stood for Every Morning Fix-it, Easy Mark's Favorite, and the like.[2]:p231 Compounding the problems was the infighting between E-M-F's principal partners, Everitt, Flanders, and Metzger. Eventually in mid-1909, Everitt and Metzger left to start a new enterprise.[16]:p88 Flanders also quit and joined them in 1912, but the Metzger Motor Car Co could not be saved from failure by renaming it the Flanders Motor Company.

Studebaker's president, Fred Fish, had purchased one-third of the E-M-F stock in 1908 and followed up by acquiring all the remainder from J. P. Morgan in 1910 and buying E-M-F's manufacturing plants at Walkerville, Ontario, Canada, and across the river in Detroit.[17] The former Ford Piquette Avenue Plant, located across Brush Street from the old E-M-F plant in the Milwaukee Junction area of Detroit, was purchased from Ford in January 1911 to become Studebaker Plant 10, used for assembly work until 1933.[18]

Studebaker marque established in 1911

In 1910, it was decided to refinance and incorporate as the Studebaker Corporation, which was concluded on 14 February 1911 under New Jersey laws.[4]:p.63 The company discontinued making electric vehicles that same year.[8]:p.71 The financing was handled by Lehman Brothers and Goldman Sachs who provided board representatives including Henry Goldman whose contribution was especially esteemed.[4]:p.76

After taking over E-M-F's facilities, Studebaker sought to remedy the customer dissatisfaction by paying mechanics to visit each disgruntled owner and replace defective parts in their vehicles, at a total cost of US$1 million. The worst problem was rear-axle failure. Hendry comments that the frenzied testing resulted in Studebaker's aim to design 'for life'—and the consequent emergence of "a series of really rugged cars... the famous Big and Special Sixes".[2]:p231 From that time, Studebaker's own marque was put on all new automobiles produced at the former E-M-F facilities as an assurance that the vehicles were well built.

Engineering advances from WWI

The corporation benefited from enormous orders cabled by the British government at the outbreak of World War I. They included 3,000 transport wagons, 20,000 sets of artillery harness, 60,000 artillery saddles, and ambulances, as well as hundreds of cars purchased through the London office. Similar orders were received from the governments of France and Russia.[4]:p.79

The 1913 six-cylinder models were the first cars to employ the important advancement of monobloc engine casting which became associated with a production-economy drive in the years of the war. At that time, a 28-year-old university graduate engineer, Fred M. Zeder, was appointed chief engineer. He was the first of a trio of brilliant technicians, with Owen R. Skelton and Carl Breer, who launched the successful 1918 models, and were known as "The Three Musketeers".[2]:p234 They left in 1920 to form a consultancy, later to become the nucleus of Chrysler Engineering. The replacement chief engineer was Guy P. Henry, who introduced molybdenum steel,[2]:p236 an improved clutch design,[19] and presided over the six-cylinders-only policy favored by new president Albert Russel Erskine who replaced Fred Fish in July 1915.[2]:p234

End of horse-drawn era

John M. Studebaker had always viewed the automobile as complementary to the horse-drawn wagon, pointing out that the expense of maintaining a car might be beyond the resources of a small farmer. In 1918, when Erskine's history of the firm was published, the annual capacity of the seven Studebaker plants was 100,000 automobiles, 75,000 horse-drawn vehicles, and about $10,000,000 worth of automobile and vehicle spare parts and harness.[4]:p.85 In the preceding seven years, 466,962 horse-drawn vehicles had been sold, as against 277,035 automobiles,[4]:p.87 but the trend was all too clear. The regular manufacture of horse-drawn vehicles ended when Erskine ordered removal of the last wagon gear in 1919.[8]:p.90 To its range of cars, Studebaker would now add a truck line to replace the horse-drawn wagons. Buses, fire engines, and even small rail locomotive-kits[20] were produced using the same powerful six-cylinder engines.

First auto proving ground

In 1925, the corporation's most successful distributor and dealer Paul G. Hoffman came to South Bend as vice-president in charge of sales. In 1926, Studebaker became the first automobile manufacturer in the United States to open a controlled outdoor proving ground on which, in 1937, would be planted 5,000 pine trees in a pattern that spelled "STUDEBAKER" when viewed from the air.[21] Also in 1926, the last of the Detroit plant was moved to South Bend under the control of Harold S Vance, vice-president in charge of production and engineering. That year, a new small car, the Erskine Six was launched in Paris, resulting in 26,000 sales abroad and many more in America.[8]:p.91 By 1929, the sales list had been expanded to 50 models and business was so good that 90 per cent of earnings were being paid out as dividends to shareholders in a highly competitive environment. However, the end of that year ushered in the Great Depression that saw many layoffs and massive national unemployment for several years.

Facilities in the 1920s

Studebaker's total plant area was 225 acres (0.91 km2), spread over three locations, with buildings occupying seven-and-a-half million square feet of floor space. Annual production capacity was 180,000 cars, requiring 23,000 employees.[2]:p237

The original South Bend vehicle plant continued to be used for small forgings, springs, and making some body parts. Separate buildings totaling over one million square feet were added in 1922–23 for the Light, Special, and Big Six models. At any one time, 5,200 bodies were in process. South Bend's Plant 2 made chassis for the Light Six and had a foundry of 575,000 sq ft (53,400 m2), producing 600 tons of castings daily.[2]:p236

Plant 3 at Detroit made complete chassis for Special and Big Six models in over 750,000 sq ft (70,000 m2) of floor space. Plant 5 was the service parts store and shipping facility, plus the executive offices of various technical departments.[2]:p236 The Detroit facilities were moved to South Bend in 1926,[8]:p.91 except that the Piquette Avenue Plant (Plant 10) was retained for assembly of the Erskine between 1927 and 1929 and the Rockne (1931-1933).[18]

Plant 7 was at Walkerville, Canada, where complete cars were assembled from South Bend, Detroit, and locally-made components for the Canadian and British Empire (right-hand-drive) trade. By locating it there, Studebaker could advertise the cars as "British-built" and qualify for reduced tariffs.[2]:p237 This manufacturing facility had been acquired from E-M-F in 1910 (see above). By 1929, it had been the subject of $1.25 million investment and was providing employment that supported 500 families.[17]

Impact of the 1930s depression

Few industrialists were prepared for the Wall Street Crash of October 1929. Though Studebaker's production and sales had been booming, the market collapsed and plans were laid for a new, small, low-cost car—the Rockne. However, times were too bad to sell even inexpensive cars. Within a year, the firm was cutting wages and laying off workers, but not quickly enough. Erskine maintained faith in the Rockne and rashly had the directors declare huge dividends in 1930 and 1931. He also acquired 95% of the White Motor Company's stock at an inflated price and in cash. By 1933, the banks were owed $6 million, though current assets exceeded that figure. On March 18, 1933, Studebaker entered receivership. Erskine was pushed out of the presidency in favor of more cost-conscious managers. Albert R. Erskine committed suicide on July 1, 1933, leaving it to successors Harold Vance and Paul Hoffman to deal with the problems.[8]:p.96–98

By December 1933, the company was back in profit with $5.75 million working capital and 224 new Studebaker dealers.[8]:p.99 With the substantial aid of Lehman Brothers, full refinancing and reorganization was achieved on March 9, 1935. A new car was put on the drawing boards under chief engineer Delmar "Barney" Roos—the Champion. Its final styling was designed by Virgil Exner and Raymond Loewy. The Champion doubled the company's previous-year sales when it was introduced in 1939.[8]:p.109

In 1938, the company built a new factory in Vernon, California which remained in production until 1956. At one time, the facility was producing 65 cars a day.[22] The factory manufactured the Champion, the Land Cruiser, and the Starlight.

World War II

From the 1920s to the 1930s, the South Bend company had originated many style and engineering milestones, including the Light Four, Light Six, Special Six, Big Six models, the record-breaking Commander and President, followed by the 1939 Champion. During World War II, Studebaker produced the Studebaker US6 truck in great quantity and the unique M29 Weasel cargo and personnel carrier. Studebaker ranked 28th among United States corporations in the value of wartime production contracts.[23][24] After cessation of hostilities, Studebaker returned to building automobiles that appealed to average Americans.

Post-WWII styling

Studebaker prepared well in advance for the anticipated post-war market and launched the slogan First by far with a post-war car. This advertising premise was substantiated by Virgil Exner's designs,[25] notably the 1947 Studebaker Starlight coupé, which introduced innovative styling features that influenced later cars, including the flatback "trunk" instead of the tapered look of the time, and a wrap-around rear window. Exner's concepts were spread through a line of models like the 1950 Studebaker Champion Starlight coupe[26] The new trunk design prompted a running joke that one could not tell if the car was coming or going.

Hamilton, Ontario plant

On August 18, 1948, surrounded by more than 400 employees and a battery of reporters, the first vehicle, a blue Champion four-door sedan, rolled off of the Studebaker assembly line in Hamilton, Ontario, Canada.[27] The company was located in the former Otis-Fenson military weapons factory off Burlington Street on Victoria Avenue North, which was built in 1941. Having previously operated its British Empire export assembly plant at Walkerville, Ontario, Studebaker settled on Hamilton as a post-war Canadian manufacturing site because of the city's centrality to the Canadian steel industry.

Industry price war brings on crisis

Studebaker's strong post-war management team including president Paul G Hoffman and Roy Cole (vice-president, engineering) had gone by 1949[2]:p252 and was replaced by more cautious executives who failed to meet the competitive challenge brought on by Henry Ford II and his Whiz Kids. Massive discounting in a price war between Ford and General Motors, which began with Ford's massive increase in production in the spring of 1953—part of Ford's postwar expansion program aimed at restoring it to the position of the largest car maker which GM had held since 1931—could not be equalled by the independent carmakers, for whom the only hope was seen as a merger of Studebaker, Packard, Hudson, and Nash into a third giant combine. This had been unsuccessfully attempted by George W. Mason. In this scheme, Studebaker had the disadvantage that its South Bend location would make centralization difficult. Its labor costs were also the highest in the industry.[2]:p254

Merger with Packard

Ballooning labor costs (the company had never had an official United Auto Workers [UAW] strike and Studebaker workers and retirees were among the highest paid in the industry), quality control issues, and the new-car sales war between Ford and General Motors in the early 1950s wreaked havoc on Studebaker's balance sheet.[2]:p254-255 Professional financial managers stressed short-term earnings rather than long-term vision. There was enough momentum to keep going for another ten years, but stiff competition and price-cutting by the Big Three doomed the enterprise.

From 1950, Studebaker declined rapidly and, by 1954, was losing money. It negotiated a strategic takeover by Packard, a smaller but less financially troubled car manufacturer. However, the cash position was worse than it had led Packard to believe and, by 1956, the company (renamed Studebaker-Packard Corporation and under the guidance of CEO James J. Nance) was nearly bankrupt, though it continued to make and market both Studebaker and Packard cars until 1958.[2]:p254 The "Packard" element was retained until 1962, when the name reverted to "Studebaker Corporation".

Contract with Curtiss-Wright

A three-year management contract was made by Nance with aircraft maker Curtiss-Wright in 1956[28] with the aim of improving finances.[2] C-W's president, Roy T. Hurley, attempted to cure Studebaker's ruinously lax employment policies. Under C-W's guidance, Studebaker-Packard also sold the old Detroit Packard plant and returned the then-new Packard plant on Conner Avenue (where Packard production had moved in 1954, at the same time Packard took its body-making operations in house after its longtime body supplier, Briggs Manufacturing, was acquired by Chrysler in late 1953.) to its lessor, Chrysler. The company became the American importer for Mercedes-Benz, Auto Union, and DKW automobiles and many Studebaker dealers sold those brands as well. C-W gained the use of idle car plants and tax relief on their aircraft profits while Studebaker-Packard received further working capital to continue car production.

Last automobiles produced

The automobiles that came after the diversification process began, including the redesigned compact Lark (1959) and the Avanti sports car (1962), were based on old chassis and engine designs. The Lark, in particular, was based on existing parts to the degree that it even utilized the central body section of the company's 1953–58 cars, but was a clever enough design to be popular in its first year, selling over 130,000 units and delivering a $28.6 million profit to the automaker. "S-P rose from 56,920 units in 1958 to 153,844 in 1959."[29]

However, Lark sales began to drop precipitously after the big three manufacturers introduced their own compact models in 1960, and the situation became critical once the so-called "senior compacts" debuted for 1961. The Lark had provided a temporary reprieve, but nothing proved enough to stop the financial bleeding.

There was a labor strike at the South Bend plant[30] starting on January 1, 1962, and lasting 38 days.[31] The strike came to an end after an agreement was reached between company president Sherwood H. Egbert and Walter P. Reuther, president of the UAW.[32] Despite a sales uptick in 1962, continuing media reports that Studebaker was about to leave the auto business became a self-fulfilling prophecy as buyers shied away from the company's products for fear of being stuck with an "orphan". NBC reporter Chet Huntley made a television program called "Studebaker—Fight for Survival" which aired on May 18, 1962.[33] By 1963, all of the company's automobiles and trucks were selling poorly.

Exit from auto business

- Closure of South Bend plant, 1963

After insufficient initial sales of the 1964 models and the ousting of president Sherwood Egbert, the company announced the closure of the South Bend plant on December 9, 1963, and produced its last car in South Bend on December 20. The shutdown of the plant, whose work force was nearly a quarter African-American, hit that community especially hard.[34] The engine foundry remained open to supply the Canadian plant until the end of the 1964 model year, after which it was also shuttered. The Avanti model name, tooling, and plant space were sold off to Leo Newman and Nate Altman, a longtime South Bend Studebaker-Packard dealership. They revived the car in 1965 under the brand name "Avanti II". (See main article Avanti cars (non-Studebaker).) They likewise purchased the rights and tooling for Studebaker's trucks, along with the company's vast stock of parts and accessories. Trucks ceased to be built after Studebaker fulfilled its remaining orders in early 1964. There were some '1965' model Champ trucks built in South America using CKD parts ( completely knocked down ). These models used a different grille than all previous Champ models.

- Closure of Hamilton plant, 1966

Limited automotive production was consolidated at the company's last remaining production facility in Hamilton, Ontario, Canada, which had always been profitable and where Studebaker produced cars until March 1966 under the leadership of Gordon Grundy. It was projected that the Canadian operation could break even on production of about 20,000 cars a year, and Studebaker's announced goal was 30,000–40,000 1965 models. While 1965 production was just shy of the 20,000 figure, the company's directors felt that the small profits were not enough to justify continued investment. Rejecting Grundy's request for funds to tool up for 1967 models, Studebaker left the automobile business on March 16, 1966 after an announcement on March 4.[35] A turquoise and white Cruiser sedan[27] was the last of fewer than 9,000 1966 models manufactured. In reality, the move to Canada had been a tactic by which production could be slowly wound down and remaining dealer franchise obligations honored. 1965 and 1966 Studebaker cars used "McKinnon" engines sourced from General Motors Canada Limited, which were based on Chevrolet's 230-cubic-inch six-cylinder and 283-cubic-inch V8 engines when Studebaker-built engines were no longer available.

The closure adversely affected not only the plant's 700 employees, who had developed a sense of collegiality around group benefits such as employee parties and day trips, but the city of Hamilton as a whole; Studebaker had been Hamilton's tenth largest employer.[27]

- Network and other assets

Many of Studebaker's dealers either closed, took on other automakers' product lines, or converted to Mercedes-Benz dealerships following the closure of the Canadian plant. Studebaker's General Products Division, which built vehicles to fulfill defense contracts, was acquired by Kaiser Industries, which built military and postal vehicles in South Bend. In 1970, American Motors (AMC) purchased the division, which still exists today as AM General.

The grove of 5,000 trees planted on the proving grounds in 1937, spelling out the Studebaker name, still stands and has proven to be a popular topic on such satellite photography sites as Google Earth.[36] The proving grounds were acquired by Bendix in 1966[6] and Bosch in 1996. After Bosch closed its South Bend operation in 2011,[37][38] a part of the proving ground was retained and, as of April 2013, has been restored to use under the name "New Carlisle Test Facility".[6][39] For many years a rumor persisted of a Studebaker graveyard. The rumor was later confirmed to be fact when the remains of many Studebaker prototype automobiles and a few trucks were discovered at a remote site within the confines of the former Studebaker proving grounds. A few of the prototypes were rescued and are in private collections. The only example of a never-produced wood-sided Champion station wagon has been restored and is on display at the Studebaker National Museum. Most of the prototypes were left to rot in direct contact with the ground and full exposure to the weather and falling trees. Attempts to remove some of these rusting bodies resulted in the bodies crumbling under their own weight as they were moved, so now they exist only in photographs.

In May 1967, Studebaker and its diversified units were merged with Wagner Electric.[40] In November 1967, Studebaker was merged with the Worthington Corporation to form Studebaker-Worthington Inc., a Delaware corporation.[41] The Studebaker name disappeared from the American business scene in 1979, when McGraw-Edison acquired Studebaker-Worthington, except for the still existing Studebaker Leasing, based in Jericho, NY. McGraw-Edison was itself purchased in 1985 by Cooper Industries, which sold off its auto-parts divisions to Federal-Mogul some years later. As detailed above, some vehicles were assembled from left-over parts and identified as Studebakers by the purchasers of the Avanti brand and surplus material from Studebaker at South Bend.

Diversified activities

By the early 1960s, Studebaker had begun to diversify away from automobiles. Numerous companies were purchased, bringing Studebaker into such diverse fields as the manufacture of tire studs and missile components.

The company's 1963 annual report listed the following divisions:

- Clarke – Floor Machine Division, Muskegon, Michigan

- CTL – Missile/Space Technology Division, Cincinnati, Ohio

- Franklin – Appliance Division, Minneapolis, Minnesota (home office; other locations also in Minnesota, Iowa, and Ontario). Manufactured private label kitchen and laundry appliances for major retailers until sold to White Consolidated Industries.[42]

- Gravely Tractor – Tractors Division, Dunbar, West Virginia, and Albany, Georgia

- International – South Bend, Indiana (handled business matters for all divisions doing business overseas)

- Onan – Engine/Generator Division, Minneapolis, Minnesota

- Paxton Automotive – automobile superchargers

- STP – Scientifically Treated Products Division, Des Plaines, Illinois, and Santa Monica, California. Produced automotive engine additives.

- Schaefer – Commercial Refrigeration Division, Minneapolis, Minnesota, and Aberdeen, Maryland

- Studebaker of Canada – Automotive Manufacturing, Hamilton, Ontario

- SASCO – Studebaker Automotive Sales Corp., South Bend, Indiana.

- Studegrip – Tire Stud Division, South Bend, Indiana, Jefferson, Iowa, and Minneapolis, Minnesota

- Trans International Airlines – founded by Kirk Kerkorian

Having built the Wright R-1820 under license during World War II, Studebaker also attempted to build what would perhaps have been the largest aircraft piston engine ever built. With 24 cylinders in an "H" configuration, a bore of 8 in (203 mm) and stroke of 7.75 in (197 mm), displacement would have been 9,349 cubic inches (153.20 L), hence the H-9350 designation. It was not completed.[43]

Advertisements

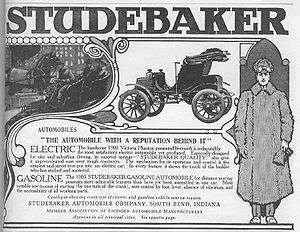

1902 advertisement |

1905 advertisement for Studebaker electric and gasoline-powered cars |

A 1909 Studebaker Advertisement – The New York Times, May 22, 1909 |

A 1924 advertisement Studebaker tile, in Tetuan street (Seville) |

Products

- See also List of Studebaker vehicles

Studebaker automobile models

- Studebaker Electric (1902–1912)

- Studebaker-Garford (1904–1911)

- Studebaker Six monobloc-engine models (1911–1918)

- Studebaker Light Four (1918–1920)

- Studebaker Big Six (1918–1927)

- Studebaker Special Six (1918–1927)

- Studebaker Light Six (includes Standard Six model) (1918–1927)

- Studebaker Commander (1927–35, 1937–58, 1964–66)

- Studebaker President (1928–42, 1955–58)

- Studebaker Dictator/Director (1927–37)

- Studebaker Champion (1939–58)

- Studebaker Land Cruiser (1934–54)

- Studebaker Conestoga (1954–55)

- Studebaker Speedster (1955)

- Studebaker Scotsman (1957–58)

- Hawk series:

- Studebaker Golden Hawk (1956–58)

- Studebaker Silver Hawk (1957–59)

- Studebaker Sky Hawk (1956)

- Studebaker Flight Hawk (1956)

- Studebaker Power Hawk (1956)

- Studebaker Hawk (1960–61)

- Studebaker Gran Turismo Hawk (1962–64)

- Studebaker Lark (1959–1966) (Includes the Lark-based 1964–66 Cruiser, Daytona, Commander, and Challenger)

- Studebaker Avanti (1962–64)

- Studebaker Wagonaire (1963–66)

Studebaker trucks

- Studebaker Coupe Express (1937–1939)

- Studebaker US6 (1941–1945)

- Studebaker M29 Weasel (1942–1945)

- Studebaker 2R Series (1949–1953)

- Studebaker 3R Series (1954)

- Studebaker E Series Truck (1955-1964)

- Studebaker Transtar (1956–1958, 1960-1964)

- Studebaker Champ (1960–1964)

- Studebaker M series (1940–1948)

- M35 2-1/2 ton cargo truck (early 1950s)

Studebaker body styles

- Studebaker Starlight (1947–55, 1958)

- Starliner

- Coupe Express

Affiliated automobile marques

- Tincher: An early independent builder of luxury cars financed by Studebaker investment, 1903–1909

- Studebaker-Garford: Studebaker-bodied cars, 1904–1911

- E-M-F: Independent auto manufacturer that marketed cars through Studebaker wagon dealers, 1909–1912

- Erskine: Brand of automobile produced by Studebaker, 1926–1930

- Pierce-Arrow: owned by Studebaker 1928–1933

- Rockne: Brand of automobile produced by Studebaker, 1932–1933

- Packard: 1954 merger partner of Studebaker

- Mercedes-Benz: Distributed through Studebaker dealers, 1958–1966

See also

- Automotive industry

- Charles Brady King

- List of defunct United States automobile manufacturers

- South Bend Watch Company (maker of Studebaker watches)

- Studebaker Canada Ltd.

- Studebaker National Museum

- Story Monument

- The Three Musketeers (Studebaker engineers)

- Tippecanoe Place

Notes

- ↑ "German heritage biography: Studebaker Brothers". Retrieved February 6, 2007.

- 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Hendry, Maurice M. Studebaker: One can do a lot of remembering in South Bend. New Albany, Indiana: Automobile Quarterly. pp. 228–275. Vol X, 3rd Q, 1972.

- ↑ E.g., see motoring review An ideal car in The Brisbane Courier, April 25, 1928

- 1 2 3 4 5 6 7 8 9 10 11 Erskine, Albert Russel (1918). History of the Studebaker corporation. Retrieved 7 February 2016.

- ↑ Genealogy at Conway's of Ireland—John Clement Studebaker

- 1 2 3 Brochure: South Bend's Titans of Industry (2012) at St Joseph County Indiana. Accessed 12 April 2013

- ↑ Register California Historic Landmark Project Collection 1936–1940

- 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Longstreet, Stephen. A Century on Wheels: The Story of Studebaker. New York: Henry Holt and Company. p. 121. 1st edn., 1952.

- ↑ Guttman, Jon. "Studebaker Wagon". Military History. WHG (July 2013): 23.

- ↑ See building No.3 on illustration Looking West from Michigan Boulevard

- ↑ The Presidential Carriage Collection at Studebaker National Museum. Accessed 7 February 2016

- ↑ "Clydesdales". Archived from the original on 2009-05-09. Retrieved February 2, 2013.

- ↑ "John Mohler Studebaker". Automotive Hall of Fame. Retrieved March 4, 2016.

- ↑ "Ex-State Senator Frederick S. Fish will leave Newark to become the general counsel of the Studebaker Brothers' Manufacturing Company at South Bend, Ind." NYT City & Suburban News, Mar 26, 1891 (PDF)

- ↑ Clymer, Floyd. Treasury of Early American Automobiles, 1877–1925 (New York: Bonanza Books, 1950), p.178.

- ↑ Yanik, Anthony J. The E-M-F Company. SAE, 2001. ISBN 0-7680-0716-X.

- 1 2 "Studebaker Factory Supports 500 Families Living in Border Area". Financial Post. Western Libraries (Ontario). October 31, 1929. Retrieved June 9, 2011.

- 1 2 National Historic Landmark Nomination - Ford Piquette Avenue Plant, pp. 22-23

- ↑ "Latest Auto Improvements Give More Comfort" Popular Mechanics, October 1930

- ↑ Petrol Motor Vehicles on Railways Bunbury Herald,Western Australia, 3 May 1919, at Trove

- ↑ Strohl, Daniel. "Studebaker's tree sign to be restored for 75th anniversary". Hemmings Daily. Hemmings Motor News. Retrieved 31 July 2013.

- ↑ Studebaker Vernon factory

- ↑ Peck, Merton J. & Scherer, Frederic M. The Weapons Acquisition Process: An Economic Analysis (1962) Harvard Business School p.619

- ↑ Herman, Arthur. Freedom's Forge: How American Business Produced Victory in World War II, pp. 81, 215-8, 312, Random House, New York, NY, 2012. ISBN 978-1-4000-6964-4.

- ↑ Virgil M. Exner’s Striking Studebaker Starlight Coupe Design. The Old Motor, 26 September 2016. Accessed 19 November 2016

- ↑ Studebaker Champion Starlight coupe in America on the Move history website

- 1 2 3 "The Hamilton Memory Project; STUDEBAKER" (Press release). The Hamilton Spectator–Souvenir Edition. 10 June 2006. p. MP45.

- ↑ Dallas Morning News, August 9, 1956, Part 3, Page 5.

- ↑ The Washington Post, Times Herald, January 6, 1960, Page 21.

- ↑ "The President & the Picket". Time. January 26, 1962. Retrieved June 9, 2011.

- ↑ Studebaker-Packard Corporation Annual Report, 1961, Page 4.

- ↑ Aberdeen Daily News, February 8, 1962, Page 7.

- ↑ Plain Dealer, May 18, 1962, Page 25

- ↑ "Negroes Lose 1,500 Posts in South Bend". Pittsburgh Courier. 21 December 1963.

- ↑ Johnson, Dale (March 4, 2006). "(Copy of)The last days of Studebaker". The Toronto Star. Archived from the original on March 15, 2007. Retrieved February 6, 2007.

- ↑ Turnbull, Alex (October 26, 2005). "Arboreal typography". Google Sightseeing. Retrieved June 9, 2011.

- ↑ Bosch Complete Plant Closure (Auction) at Britton Management Group, November 2011

- ↑ Ferreira, Colleen Bosch plant to close in South Bend at wsbt.com news, 16 November 2010 Archived July 23, 2011, at the Wayback Machine.

- ↑ History of the New Carlisle Test Facility at Bosch US website

- ↑ Wagner Electric, Studebaker Vote To Merger Firms Toledo Blade 10 May 1967, p 70. At Google News, accessed 24 March 2013

- ↑ Studebaker, Worthington Vote Merger Despite Antitrust Montreal Gazette 16 November 1967, p 14. At Google News, accessed 24 March 2013

- ↑ White company history at fundinguniverse.com

- ↑ The U.S. Air Force project designation MX-232 was allocated to the proposed 5000-hp engine, according to researchers George Cully & Andreas Parsch. See explanation and link from Designations Of U.S. Air Force Projects (2005)

References

- Erskine, A R History of the Studebaker Corporation, South Bend (1918) (online Google Books—free download)

- Longstreet, Stephen A Century on Wheels: The Story of Studebaker, A History, 1852–1952, Henry Holt and Co, N.Y. (1952)

- Bonsall, Thomas E More Than They Promised: The Studebaker Story Stanford University Press (2000)

- Foster, Patrick Studebaker: America's Most Successful Independent Automaker Motorbooks

- Grist, Peter Virgil Exner: Visioneer: The official biography of Virgil M. Exner, designer extraordinaire Veloce, USA

Further reading

- Clement Studebaker House, Tippecanoe Place National Register of Historic Places Inventory—Nomination Form. (The heritage research includes details of the early history of the firm at South Bend.)

- Severson A. Lark and Super Lark: The Last Days of Studebaker at Ate Up With Motor October 17, 2009

External links

| Wikimedia Commons has media related to Studebaker vehicles. |

- 1963 model range at RitzSite

- The Studebaker Drivers Club

- From Horses to Horsepower: Studebaker Helped Move a Nation by Kent C. Boese (Smithsonian Institution)

- The Studebaker National Museum

- How Studebaker Works by Consumer Guide Auto Editors

- StudebakerHistory.com

- E-M-F history pages

- Photos of the South Bend plant pre-demolition 2005

- History of Clem Studebaker's mansion at South Bend

- Early Studebaker vehicles—Images at Utah State History