Microfluidics

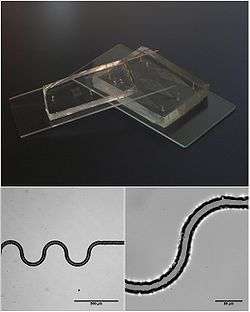

Microfluidics deals with the behaviour, precise control and manipulation of fluids that are geometrically constrained to a small, typically sub-millimeter, scale. It is a multidisciplinary field intersecting engineering, physics, chemistry, biochemistry, nanotechnology, and biotechnology, with practical applications to the design of systems in which low volumes of fluids are processed to achieve multiplexing, automation, and high-throughput screening.[1] Microfluidics emerged in the beginning of the 1980s and is used in the development of inkjet printheads, DNA chips, lab-on-a-chip technology, micro-propulsion, and micro-thermal technologies.

Typically, micro means one of the following features:

- small volumes (μL, nL, pL, fL)

- small size

- low energy consumption

- effects of the microdomain

Typically fluids are moved, mixed, separated or otherwise processed. Numerous applications employ passive fluid control techniques like capillary forces. In some applications, external actuation means are additionally used for a directed transport of the media. Examples are rotary drives applying centrifugal forces for the fluid transport on the passive chips. Active microfluidics refers to the defined manipulation of the working fluid by active (micro) components such as micropumps or microvalves. Micropumps supply fluids in a continuous manner or are used for dosing. Microvalves determine the flow direction or the mode of movement of pumped liquids. Often processes which are normally carried out in a lab are miniaturised on a single chip in order to enhance efficiency and mobility as well as reducing sample and reagent volumes.

Microscale behaviour of fluids

The behaviour of fluids at the microscale can differ from "macrofluidic" behaviour in that factors such as surface tension, energy dissipation, and fluidic resistance starts to dominate the system. Microfluidics studies how these behaviours change, and how they can be worked around, or exploited for new uses.[2][3][4][5]

At small scales (channel size of around 100 nanometers to 500 micrometers) some interesting and sometimes unintuitive properties appear. In particular, the Reynolds number (which compares the effect of the momentum of a fluid to the effect of viscosity) can become very low. A key consequence is co-flowing fluids do not necessarily mix in the traditional sense, as flow becomes laminar rather than turbulent; molecular transport between them must often be through diffusion.[6]

High specificity of chemical and physical properties (concentration, pH, temperature, shear force, etc.) can also be ensured resulting in more uniform reaction conditions and higher grade products in single and multi-step reactions.[7][8]

Key application areas

Microfluidic structures include micropneumatic systems, i.e. microsystems for the handling of off-chip fluids (liquid pumps, gas valves, etc.), and microfluidic structures for the on-chip handling of nanoliter (nl) and picoliter (pl) volumes.[9] To date, the most successful commercial application of microfluidics is the inkjet printhead.[10] and other industrially relevant materials (e.g., polymer particles).[11] Additionally, advances in microfluidic manufacturing allow the devices to be produced in low-cost plastics[12] and part quality may be verified automatically.[13]

Advances in microfluidics technology are revolutionizing molecular biology procedures for enzymatic analysis (e.g., glucose and lactate assays), DNA analysis (e.g., polymerase chain reaction and high-throughput sequencing), and proteomics. The basic idea of microfluidic biochips is to integrate assay operations such as detection, as well as sample pre-treatment and sample preparation on one chip.[15][16]

An emerging application area for biochips is clinical pathology, especially the immediate point-of-care diagnosis of diseases. In addition, microfluidics-based devices, capable of continuous sampling and real-time testing of air/water samples for biochemical toxins and other dangerous pathogens, can serve as an always-on "bio-smoke alarm" for early warning.

Continuous-flow microfluidics

These technologies are based on the manipulation of continuous liquid flow through microfabricated channels. Actuation of liquid flow is implemented either by external pressure sources, external mechanical pumps, integrated mechanical micropumps, or by combinations of capillary forces and electrokinetic mechanisms.[17][18] Continuous-flow microfluidic operation is the mainstream approach because it is easy to implement and less sensitive to protein fouling problems. Continuous-flow devices are adequate for many well-defined and simple biochemical applications, and for certain tasks such as chemical separation, but they are less suitable for tasks requiring a high degree of flexibility or fluid manipulations. These closed-channel systems are inherently difficult to integrate and scale because the parameters that govern flow field vary along the flow path making the fluid flow at any one location dependent on the properties of the entire system. Permanently etched microstructures also lead to limited reconfigurability and poor fault tolerance capability.

Process monitoring capabilities in continuous-flow systems can be achieved with highly sensitive microfluidic flow sensors based on MEMS technology which offers resolutions down to the nanoliter range.

Droplet-based microfluidics

Droplet-based microfluidics as a subcategory of microfluidics in contrast with continuous microfluidics has the distinction of manipulating discrete volumes of fluids in immiscible phases with low Reynolds number and laminar flow regimes. Interest in droplet-based microfluidics systems has been growing substantially in past decades. Microdroplets offer the feasibility of handling miniature volumes (μl to fl) of fluids conveniently, provide better mixing, encapsulation, sorting, sensing and are suitable for high throughput experiments.[19] Exploiting the benefits of droplet-based microfluidics efficiently requires a deep understanding droplet generation [20] to perform various logical operations[21][22] such as droplet motion, droplet sorting, droplet merging, and droplet breakup.[23]

Two immiscible phases used for the droplet generation are termed as the continuous phase (medium in which droplets are generated) and dispersed phase (the droplet phase). The size of the generated droplets is mainly controlled by the flow rates of the continuous phase and dispersed phase, interfacial tension between two phases and the geometry used for the droplet generation.[24][21] Generally, three types of microfluidic geometries are utilised for the droplet generation : (i) T-Junction, (ii) Flow Focusing, and (iii) Co-Flowing. T-junction geometry follows a linear scaling law [25] for the droplet generation and hence, simple to use.

Micromagnetofluidic method,[26] which is the control of magnetic fluids by an applied magnetic field on a microfluidic platform,[27] offers wireless and programmable control of the magnetic droplets.[28][29] Hence, the magnetic force can also be used to perform various logical operations,[30][31] in addition to the hydrodynamic force and the surface tension force.[28][29] The magnetic field strength, type of the magnetic field (gradient, uniform or rotating), magnetic susceptibility, interfacial tension, flow rates, and flow rate ratios determine the control of the microdroplets on a micromagnetofluidic platform.[28]

One of the key advantages of droplet-based microfluidics is the ability to use droplets as incubators for single cells.[19][32]

Devices capable of generating thousands of droplets per second opens new ways characterise cell population, not only based on a specific marker measured at a specific time point but also based on cells kinetic behaviour such as protein secretion, enzyme activity or proliferation.[33] Recently, a method was found to generate a stationary array of microscopic droplets for single-cell incubation that does not require the use of a surfactant .[34]

Digital microfluidics

Alternatives to the above closed-channel continuous-flow systems include novel open structures, where discrete, independently controllable droplets are manipulated on a substrate using electrowetting. Following the analogy of digital microelectronics, this approach is referred to as digital microfluidics. Le Pesant et al. pioneered the use of electrocapillary forces to move droplets on a digital track.[35] The "fluid transistor" pioneered by Cytonix[36] also played a role. The technology was subsequently commercialised by Duke University. By using discrete unit-volume droplets,[20] a microfluidic function can be reduced to a set of repeated basic operations, i.e., moving one unit of fluid over one unit of distance. This "digitisation" method facilitates the use of a hierarchical and cell-based approach for microfluidic biochip design. Therefore, digital microfluidics offers a flexible and scalable system architecture as well as high fault-tolerance capability. Moreover, because each droplet can be controlled independently, these systems also have dynamic reconfigurability, whereby groups of unit cells in a microfluidic array can be reconfigured to change their functionality during the concurrent execution of a set of bioassays. Although droplets are manipulated in confined microfluidic channels, since the control on droplets is not independent, it should not be confused as "digital microfluidics". One common actuation method for digital microfluidics is electrowetting-on-dielectric (EWOD). Many lab-on-a-chip applications have been demonstrated within the digital microfluidics paradigm using electrowetting. However, recently other techniques for droplet manipulation have also been demonstrated using surface acoustic waves, optoelectrowetting, mechanical actuation,[37] etc.

DNA chips (microarrays)

Early biochips were based on the idea of a DNA microarray, e.g., the GeneChip DNAarray from Affymetrix, which is a piece of glass, plastic or silicon substrate, on which pieces of DNA (probes) are affixed in a microscopic array. Similar to a DNA microarray, a protein array is a miniature array where a multitude of different capture agents, most frequently monoclonal antibodies, are deposited on a chip surface; they are used to determine the presence and/or amount of proteins in biological samples, e.g., blood. A drawback of DNA and protein arrays is that they are neither reconfigurable nor scalable after manufacture. Digital microfluidics has been described as a means for carrying out Digital PCR.

Molecular biology

In addition to microarrays, biochips have been designed for two-dimensional electrophoresis,[38] transcriptome analysis,[39] and PCR amplification.[40] Other applications include various electrophoresis and liquid chromatography applications for proteins and DNA, cell separation, in particular, blood cell separation, protein analysis, cell manipulation and analysis including cell viability analysis [19] and microorganism capturing.[16]

Evolutionary biology

By combining microfluidics with landscape ecology and nanofluidics, a nano/micro fabricated fluidic landscape can be constructed by building local patches of bacterial habitat and connecting them by dispersal corridors. The resulting landscapes can be used as physical implementations of an adaptive landscape,[41] by generating a spatial mosaic of patches of opportunity distributed in space and time. The patchy nature of these fluidic landscapes allows for the study of adapting bacterial cells in a metapopulation system. The evolutionary ecology of these bacterial systems in these synthetic ecosystems allows for using biophysics to address questions in evolutionary biology.

Cell behavior

The ability to create precise and carefully controlled chemoattractant gradients makes microfluidics the ideal tool to study motility, chemotaxis and the ability to evolve / develop resistance to antibiotics in small populations of microorganisms and in a short period of time. These microorganisms including bacteria [42] and the broad range of organisms that form the marine microbial loop,[43] responsible for regulating much of the oceans' biogeochemistry.

Microfluidics has also greatly aided the study of durotaxis by facilitating the creation of durotactic (stiffness) gradients.

Cellular biophysics

By rectifying the motion of individual swimming bacteria,[44] microfluidic structures can be used to extract mechanical motion from a population of motile bacterial cells.[45] This way, bacteria-powered rotors can be built.[46][47]

Optics

The merger of microfluidics and optics is typical known as optofluidics. Examples of optofluidic devices are tunable microlens arrays[48][49] and optofluidic microscopes.

Microfluidic flow enables fast sample throughput, automated imaging of large sample populations, as well as 3D capabilities.[50][51] or superresolution.[52]

Acoustic droplet ejection (ADE)

Acoustic droplet ejection uses a pulse of ultrasound to move low volumes of fluids (typically nanoliters or picoliters) without any physical contact. This technology focuses acoustic energy into a fluid sample in order to eject droplets as small as a millionth of a millionth of a litre (picoliter = 10−12 litre). ADE technology is a very gentle process, and it can be used to transfer proteins, high molecular weight DNA and live cells without damage or loss of viability. This feature makes the technology suitable for a wide variety of applications including proteomics and cell-based assays.

Fuel cells

Microfluidic fuel cells can use laminar flow to separate the fuel and its oxidant to control the interaction of the two fluids without a physical barrier as would be required in conventional fuel cells.[53][54][55]

A tool for cell biological research

Microfluidic technology has led to the creation of powerful tools for cell biologists to control the complete cellular environment, leading to new questions and new discoveries.[56] Many diverse advantages of this technology for microbiology are listed below:

- Single cell studies [19]

- Microenvironmental control: ranging from mechanical environment [57] to chemical environment [58]

- Precise spatiotemporal concentration gradients [59]

- Mechanical deformation

- Force measurements of adherent cells

- Confining cells [60]

- Exerting a controlled force [60][61]

- Fast and precise temperature control [62][63]

- Electric field integration [60]

- Cell culture [19]

- Plant on a chip and plant tissue culture [64]

- Antibiotic resistance: microfluidic devices can be used as heterogeneous environments for microorganisms. In a heterogeneous environment, it is easier for a microorganism to evolve. This can be useful for testing the acceleration of evolution of a microorganism / for testing the development of antibiotic resistance.

Future Directions

See also

References

- ↑ Volpatti, L. R.; Yetisen, A. K. (Jul 2014). "Commercialization of microfluidic devices". Trends in Biotechnology. 32 (7): 347–350. doi:10.1016/j.tibtech.2014.04.010.

- ↑ S.C.Terry,J.H.Jerman and J.B.Angell:A Gas Chromatographic Air Analyzer Fabricated on a Silicon Wafer,IEEE Trans.Electron Devices,ED-26,12(1979)1880-1886.

- ↑ Kirby, B.J. (2010). Micro- and Nanoscale Fluid Mechanics: Transport in Microfluidic Devices. Cambridge University Press.

- ↑ Karniadakis, G.M., Beskok, A., Aluru, N. (2005). Microflows and Nanoflows. Springer Verlag.

- ↑ Bruus, H. (2007). Theoretical Microfluidics. Oxford University Press.

- ↑ Tabeling, P. (2005). Introduction to Microfluidics. Oxford University Press.

- ↑ V. Chokkalingam, B. Weidenhof, M. Kraemer, W. F. Maier, S. Herminghaus, and R. Seemann,"Optimized droplet-based microfluidics scheme for sol–gel reactions" Lab Chip, 2010, doi:10.1039/b926976b.

- ↑ J Shestopalov, J. D. Tice and R. F. Ismagilov,"Multi-step synthesis of nanoparticles performed on millisecond time scale in a microfluidic droplet-based system" Lab Chip, 2004, 4, 316 - 321, doi:10.1039/b403378g.

- ↑ Nguyen, N.T., Wereley, S. (2006). Fundamentals and Applications of Microfluidics. Artech House.

- ↑ Andrew (2006). "Control and detection of chemical reactions in microfluidic systems". Nature. 442 (7101): 394–402. Bibcode:2006Natur.442..394D. doi:10.1038/nature05062.

- ↑ Wei Li, Jesse Greener, Dan Voicu and Eugenia Kumacheva "Multiple modular microfluidic (M3) reactors for the synthesis of polymer particles" Lab Chip, 2009, 9, 2715 - 2721, doi:10.1039/b906626h.

- ↑ Ryan S. Pawell, David W. Inglis, Tracie J. Barber, and Robert A. Taylor, Manufacturing and wetting low-cost microfluidic cell separation devices, Biomicrofluidics 7, 056501 (2013); doi:10.1063/1.4821315

- ↑ Automating microfluidic part verification - Online First - Springer

- ↑ S. Hu, S. Zeng, B. Zhang, C. Yang, P. Song, D.J.H. Tng, G. Lin, Y. Wang, T. Anderson, P. Coquet, L. Liu, X. Zhang, and K.-T. Yong "Preparation of biofunctionalized quantum dots using microfluidic chips for bioimaging" Analyst, 2014, 1-21, doi:10.1039/c4an00773e.

- ↑ Herold, KE; Rasooly, A (editor) (2009). Lab-on-a-Chip Technology: Fabrication and Microfluidics. Caister Academic Press. ISBN 978-1-904455-46-2.

- 1 2 Herold, KE; Rasooly, A (editor) (2009). Lab-on-a-Chip Technology: Biomolecular Separation and Analysis. Caister Academic Press. ISBN 978-1-904455-47-9.

- ↑ Chang, H.C., Yeo, Leslie (2009). Electrokinetically Driven Microfluidics and Nanofluidics. Cambridge University Press.

- ↑ fluid transistor Archived July 8, 2011, at the Wayback Machine.

- 1 2 3 4 5 Venkat Chokkalingam, Jurjen Tel, Florian Wimmers, Xin Liu, Sergey Semenov, Julian Thiele, Carl G. Figdor, Wilhelm T.S. Huck, Probing cellular heterogeneity in cytokine-secreting immune cells using droplet-based microfluidics, Lab on a Chip, 13, 4740-4744, 2013, DOI: 10.1039/C3LC50945A, http://pubs.rsc.org/en/content/articlelanding/2013/lc/c3lc50945a#!divAbstract

- 1 2 V. Chokkalingam, S. Herminghaus, and R. Seemann,"Self-synchronizing Pairwise Production of Monodisperse Droplets by Microfluidic Step Emulsification" Applied Physics Letters 93, 254101, 2008.

- 1 2 Teh, Shia-Yen and Lin, Robert and Hung, Lung-Hsin and Lee, Abraham P (2008). "Droplet microfluidics". Lab on a Chip. Royal Society of Chemistry. 8 (2): 198–220. doi:10.1039/B715524G.

- ↑ Prakash, Manu; Gershenfeld, Neil (2007-02-09). "Microfluidic Bubble Logic". Science. 315 (5813): 832–835. doi:10.1126/science.1136907. ISSN 0036-8075. PMID 17289994.

- ↑ Samie, Milad; Salari, Shafii (May 2013). "Breakup of microdroplets in asymmetric T junctions". Physical Review E. 87 (05). Bibcode:2013PhRvE..87e3003S. doi:10.1103/PhysRevE.87.053003.

- ↑ Varma, Vijaykumar; Ray, Ayan; Wang, Z. M.; Wang, Z. P.; Ramanujan, R. V. (2016). "Droplet Merging on a Lab-on-a-Chip Platform by Uniform Magnetic Fields". Scientific Reports. 6: 37671 (In Press). doi:10.1038/srep37671 – via Nature Publishing Group.

- ↑ Garstecki, Piotr and Fuerstman, Michael J and Stone, Howard A and Whitesides, George M (2006). "Formation of droplets and bubbles in a microfluidic T-junction—scaling and mechanism of break-up" (PDF). Lab on a Chip. Royal Society of Chemistry. 6 (3): 437–446.

- ↑ Wang, Zhaomeng; Varma, V. B.; Xia, Huan Ming; Wang, Z. P.; Ramanujan, R. V. (2015-05-01). "Spreading of a ferrofluid core in three-stream micromixer channels". Physics of Fluids (1994-present). 27 (5): 052004. doi:10.1063/1.4919927. ISSN 1070-6631.

- ↑ Pamme,N. (2006). "Magnetism and microfluidics". Lab Chip. 6: 24–38. doi:10.1039/B513005K.

- 1 2 3 Varma, V. B. and Ray, A. and Wang, Z. M. and Wang, Z. P. and Wu, R. G. and Jayaneel, P. J. and Sudharsan, N. M. and Ramanujan, R. V. (2016). "Control of Ferrofluid Droplets in Microchannels by Uniform Magnetic Fields". IEEE Magnetics Letters. IEEE. 7: 1–5. doi:10.1109/LMAG.2016.2594165.

- 1 2 Ray, A.; Varma, V. B.; Wang, Z.; Wang, Z.; Jayaneel, P. J.; Sudharsan, N. M.; Ramanujan, R. V. (2016-01-01). "Magnetic Droplet Merging by Hybrid Magnetic Fields". IEEE Magnetics Letters. PP (99): 1–1. doi:10.1109/LMAG.2016.2613065. ISSN 1949-307X.

- ↑ Teh, Shia-Yen; Lin, Robert; Hung, Lung-Hsin; Lee, Abraham P. (2008-01-29). "Droplet microfluidics". Lab on a Chip. 8 (2). doi:10.1039/B715524G. ISSN 1473-0189.

- ↑ Katsikis, Georgios; Cybulski, James S.; Prakash, Manu (2015-07-01). "Synchronous universal droplet logic and control". Nature Physics. 11 (7): 588–596. doi:10.1038/nphys3341. ISSN 1745-2473.

- ↑ Joensson, Haakan; Andersson Svahn, Helene (May 2012). "Droplet Microfluidics—A Tool for Single-Cell Analysis". Angewandte Reviews. 51 (1). doi:10.1002/anie.201200460.

- ↑ Shia Yen, Teh; Lin, Robert. "droplet microfluidics". Lab on a Chip. 8.

- ↑ Shemesh, Jonathan; Ben Arye, Tom; Avesar, Jonathan; Kang, Joo; Fine, Amir; Super, Michael; Meller, Amit; Donald, Ingber; Levenberg, Shulamit. "Stationary nanoliter droplet array with a substrate of choice for single adherent nonadherent cell incubation and analysis". Proc Natl Acad Sci U S A. 31 (8). doi:10.1073/pnas.1404472111.

- ↑ Le Pesant et al., Electrodes for a device operating by electrically controlled fluid displacement, U.S. Pat. No. 4,569,575, Feb. 11, 1986.

- ↑ NSF Award Search: Advanced Search Results

- ↑ J. Shemesh, A. Bransky, M. Khoury, S. Levenberg,"Advanced microfluidic droplet manipulation based on piezoelectric actuation" Biomedical Microdevices doi:10.1007/s10544-010-9445-y, 2010.

- ↑ Fan; et al. (2009). "Two-Dimensional Electrophoresis in a Chip". Lab-on-a-Chip Technology: Biomolecular Separation and Analysis. Caister Academic Press. ISBN 978-1-904455-47-9.

- ↑ Bontoux; et al. (2009). "Elaborating Lab-on-a-Chips for Single-cell Transcriptome Analysis". Lab-on-a-Chip Technology: Biomolecular Separation and Analysis. Caister Academic Press. ISBN 978-1-904455-47-9.

- ↑ Cady, NC (2009). "Microchip-based PCR Amplification Systems". Lab-on-a-Chip Technology: Biomolecular Separation and Analysis. Caister Academic Press. ISBN 978-1-904455-47-9.

- ↑ Keymer J.E.; P. Galajda; C. Muldoon R. & R. Austin (November 2006). "Bacterial metapopulations in nanofabricated landscapes". PNAS. 103 (46): 17290–295. Bibcode:2006PNAS..10317290K. doi:10.1073/pnas.0607971103. PMC 1635019

. PMID 17090676.

. PMID 17090676. - ↑ Ahmed, T.; Shimizu, T.S.; Stocker, R. (2010). "Microfluidics for bacterial chemotaxis". Integrative Biology. 2: 604–629. doi:10.1039/C0IB00049C.

- ↑ Seymour, J.R.; Simo', R.; Ahmed, T.; Stocker, R. (2010). "Chemoattraction to dimethylsulfoniopropionate throughout the marine microbial food web". Science. 329 (5989): 342–345. Bibcode:2010Sci...329..342S. doi:10.1126/science.1188418.

- ↑ Galajda P; J.E. Keymer; P Chaikin; R. Austin (December 2007). "A Wall of Funnels Concentrates Swimming Bacteria". Journal of Bacteriology. 189 (23): 8704–8707. doi:10.1128/JB.01033-07.

- ↑ Angelani L.; R. Di Leonardo; G. Ruocco (2009). "Self-Starting Micromotors in a Bacterial Bath". Phys. Rev. Lett. 102: 048104. arXiv:0812.2375

. Bibcode:2009PhRvL.102d8104A. doi:10.1103/PhysRevLett.102.048104.

. Bibcode:2009PhRvL.102d8104A. doi:10.1103/PhysRevLett.102.048104. - ↑ Di Leonardo, R.; Angelani, L.; Ruocco, G.; Iebba, V.; Conte, M.P.; Schippa, S.; De Angelis, F.; Mecarini, F.; Di Fabrizio, E. (2010). "A bacterial ratchet motor". PNAS. 107 (21): 9541–9545. arXiv:0910.2899

. Bibcode:2010PNAS..107.9541D. doi:10.1073/pnas.0910426107.

. Bibcode:2010PNAS..107.9541D. doi:10.1073/pnas.0910426107. - ↑ Sokolova A.; M.M. Apodacac; B.A. Grzybowskic; I.S. Aransona (December 2009). "Swimming bacteria power microscopic gears". PNAS. 107 (3): 969–974. Bibcode:2010PNAS..107..969S. doi:10.1073/pnas.0913015107.

- ↑ Liquid micro-lens array activated by selective electrowetting on lithium niobate substrates S. Grilli, L. Miccio, V. Vespini, A. Finizio, S. De Nicola, and P. Ferraro Optics Express 16, 8084-8093 (2008). doi:10.1364/OE.16.008084

- ↑ P. Ferraro, L. Miccio, S. Grilli, A. Finizio, S. De Nicola, and V. Vespini, "Manipulating Thin Liquid Films for Tunable Microlens Arrays," Optics & Photonics News 19, 34-34 (2008) http://www.opticsinfobase.org/abstract.cfm?URI=OPN-19-12-34

- ↑ Flow-scanning optical tomography N. C. Pégard, M. L. Toth, M. Driscoll, and J. W. Fleischer Lab Chip, (2014),14, 4447-4450

- ↑ N. C. Pégard and J. W. Fleischer, Journal of Biomedical Optics 18 040503 (2013)

- ↑ C-H. Lu, N. C. Pégard and J. W. Fleischer, 2013, Applied Physics Letters, 102 161115 (2013)

- ↑ Water Management in PEM Fuel Cells Archived June 28, 2008, at the Wayback Machine.

- ↑ Building a Better Fuel Cell Using Microfluidics

- ↑ Fuel Cell Initiative at MnIT Microfluidics Laboratory

- ↑ Examples in each list of paper in item Team in:""

- ↑ Amir Manbachi, Shamit Shrivastava, Margherita Cioffi, Bong Geun Chung, Matteo Moretti, Utkan Demirci, Marjo Yliperttula and Ali Khademhosseini (2008). "Microcirculation within grooved substrates regulates cell positioning and cell docking inside microfluidic channels". Lab Chip. 8 (5): 747–754. doi:10.1039/B718212K. PMC 2668874

. PMID 18432345.

. PMID 18432345. - ↑ Marjo Yliperttulaa, Bong Geun Chunga, Akshay Navaladia, Amir Manbachi, Arto Urtt (October 2008). "High-throughput screening of cell responses to biomaterials". European Journal of Pharmaceutical Sciences. 35 (3): 151–160. doi:10.1016/j.ejps.2008.04.012. PMID 18586092.

- ↑ Chung BG, Manbachi A, Saadi W, Lin F, Jeon NL, Khademhosseini A (2007). "A gradient-generating microfluidic device for cell biology.". J Vis Exp. 7 (7): 271. doi:10.3791/271. PMC 2565846

. PMID 18989442.

. PMID 18989442. - 1 2 3 Choi, J.W., Rosset, S., Niklaus, M., Adleman, J.R., Shea, H., Psaltis, D. "3-dimensional electrode patterning within a microfluidic channel using a metal ion implantation", Lab on a Chip 10, 738-788, 2010. doi:10.1039/B917719A

- ↑ "Nano today 2010"

- ↑ "Lab on a Chip 2011"

- ↑ "CherryTemp temperature control system on chip"

- ↑ AK Yetisen, L Jiang, J R Cooper, Y Qin, R Palanivelu and Y Zohar (May 2011). "A microsystem-based assay for studying pollen tube guidance in plant reproduction.". J. Micromech. Microeng. 25.

- ↑ Jesse Greener*, Ethan Tumarkin*, Michael Debono, Chi-Hang Kwan, Milad Abolhasani, Axel Guenther and Eugenia Kumacheva "Development and applications of a microfluidic reactor with multiple analytical probes" Analyst, 2012, 137, 444-450, doi:10.1039/C1AN15940B.

- ↑ Jesse Greener, Ethan Tumarkin, Michael Debono, Eugenia Kumacheva "Education: a microfluidic platform for university-level analytical chemistry laboratories" Lab Chip, 2012, 12, 696-701, doi:10.1039/C2LC20951A.

Further reading

Review Papers

- Yetisen A. K. (2013). "Paper-based microfluidic point-of-care diagnostic devices". Lab on a Chip. doi:10.1039/C3LC50169H.

- Whitesides G. M. (2006). "The origins and the future of microfluidics". Nature. 442 (7101): 368–373. Bibcode:2006Natur.442..368W. doi:10.1038/nature05058. PMID 16871203.

- Seemann Ralf; Brinkmann Martin; Pfohl Thomas; Herminghaus Stephan (2012). "Droplet based microfluidics". Reports on Progress in Physics. 75: 016601. Bibcode:2012RPPh...75a6601S. doi:10.1088/0034-4885/75/1/016601.

- Squires T. M.; Quake S. R. (2005). "Microfluidics: Fluid physics at the nanoliter scale". Reviews of Modern Physics. 77: 977–1026. Bibcode:2005RvMP...77..977S. doi:10.1103/RevModPhys.77.977.

- Yetisen A. K. (2014). "Patent Protection and Licensing in Microfluidics". Lab on a Chip. doi:10.1039/C4LC00399C.

- Chen, K. (2011). "Microfluidics and the future of drug research". The University of Toronto Journal of Undergraduate Life Sciences. 5 (1): 66–69.

- James B. Angell; Stephen C. Terry; Phillip W. Barth (April 1983). "Silicon Micromechanical Devices". Scientific American. 248 (4): 44–55. Bibcode:1983SciAm.248...44A. doi:10.1038/scientificamerican0483-44.

- Dario Carugo; Elisabetta Bottaro; Joshua Owen (April 2016). "Liposome production by microfluidics: potential and limiting factors". Scientific Reports. doi:10.1038/srep25876.

Books

- Bruus, Henrik (2008). Theoretical Microfluidics. Oxford University Press. ISBN 978-0199235094.

- Herold, KE; Rasooly, A (editor) (2009). Lab-on-a-Chip Technology: Fabrication and Microfluidics. Caister Academic Press. ISBN 978-1-904455-46-2.

- Title: Advances in Microfluidics, Editor: Dr. Ryan kelly, Pacific Northwest National Laboratory, Richland, Washington, USA. ISBN 978-953-510-106-2, 2012.

- Tabeling, P (2006). Introduction to Microfluidics. Oxford University Press. ISBN 0-19-856864-9.

- Jenkins, G; Mansfield, CD (editors) (2012). Microfluidic Diagnostics. Humana Press. ISBN 978-1-62703-133-2.

- Li, Xiujun (James); Zhou, Yu (editors) (2013). Microfluidic devices for biomedical applications. Woodhead Publishing. ISBN 978-0-85709-697-5.

| Wikimedia Commons has media related to Microfluidics. |

| Wikibooks has a book on the topic of: Microfluidics |