Metrology

Metrology is the science of measurement and includes all theoretical and practical aspects of measurement.

Metrology is defined by the International Bureau of Weights and Measures (BIPM) as "the science of measurement, embracing both experimental and theoretical determinations at any level of uncertainty in any field of science and technology."[1] The ontology and international vocabulary of metrology (VIM) is maintained by the Joint Committee for Guides in Metrology (JCGM), a group made up of eight international organisations – BIPM, IEC, IFCC, ISO, IUPAC, IUPAP, OIML, and ILAC.[2]

Metrology is a broad field divided into three basic, overlapping activities:[3][4]

- Definition of internationally accepted units of measurement

- Realisation of these units of measurement in practice

- Application of chains of traceability linking measurements made in practice to reference standards

Metrology also has three basic subfields that all use the three basic activities to varying degrees:[3]

- Scientific or fundamental metrology

- Applied, technical or industrial metrology

- Legal metrology

Scientific or fundamental metrology

Scientific and fundamental metrology concerns the establishment of quantity systems, unit systems, units of measurement, the development of new measurement methods, realization of measurement standards, and the transfer of traceability from these standards to users in society. The BIPM maintains a database of the metrological calibration and measurement capabilities of various institutes around the world. These institutes, whose activities are peer-reviewed, provide the top-level reference points for metrological traceability. In the area of measurement, the BIPM has identified nine metrology areas, including length, mass, and time.[5]

Applied, technical or industrial metrology

Applied, technical or industrial metrology concerns the application of measurement science to manufacturing and other processes and their use in society, ensuring the suitability of measurement instruments, their calibration and quality control of measurements. Although the emphasis in this area of metrology is on the measurements themselves, traceability of the calibration of the measurement devices is necessary to ensure confidence in the measurements.

Legal metrology

Legal metrology "concerns activities which result from statutory requirements and concern measurement, units of measurement, measuring instruments and methods of measurement and which are performed by competent bodies."[6] Such statutory requirements might arise from, amongst others, the needs for protection of health, public safety, the environment, enabling taxation, protection of consumers and fair trade. The OIML was set up to assist in harmonising such regulations across national boundaries to ensure that legal requirements do not inhibit trade. In Europe WELMEC was established to promote cooperation on the field of legal metrology.

Metrological traceability

A core concept in metrology is metrological traceability,[7] defined by the Joint Committee for Guides in Metrology as "property of a measurement result whereby the result can be related to a reference through a documented unbroken chain of calibrations, each contributing to the measurement uncertainty".[8] Metrological traceability permits comparison of measurements, whether the result is compared to the previous result in the same laboratory, a measurement result a year ago, or to the result of a measurement performed anywhere else in the world.

Traceability is most often obtained by calibration, establishing the relation between the indication of a measuring instrument and the value of a measurement standard. These standards are usually coordinated by national metrological institutes: National Institute of Standards and Technology; National Physical Laboratory, UK; Physikalisch-Technische Bundesanstalt; etc.

Traceability, accuracy, precision, systematic bias, evaluation of measurement uncertainty are critical parts of a quality management system.

Society

Sufficiently correct measurements are essential to commerce. About nine out of every ten people working in metrology specialize in commercial measurement, most at the technician level. Correct measurements are beneficial to manufacturing, but other methods are available and sometimes are more appropriate.

Metrology has thrived at the interface between science and manufacturing. Aerospace, commercial nuclear power, medicine, medical devices and semiconductors rely on metrology to translate theoretical science into mass-produced reality.

The basic concepts of metrology appear simple on the surface, and metrology is rarely taught in a systematic manner above the technician level. Within most businesses, metrology core beliefs such as recording all setups and observations for possible future reference are opposed to the general business practice of minimizing recordkeeping to limit litigation effects.

Applied metrology

Metrology laboratories are places where both metrology and calibration work are performed. Calibration laboratories generally specialize in calibration work only.

Both metrology and calibration laboratories must isolate the work performed from influences that might affect the work. Temperature, humidity, vibration, electrical power supply, radiated energy and other influences are often controlled. Generally, it is the rate of change or instability that is more detrimental than whatever value prevails.

Calibration technicians execute calibration work. In large organizations, the work is further divided into three groups:

| Group | Definition |

|---|---|

| Set-up people | arrange the equipment needed for calibration and verify that it works correctly. |

| Operators | execute the calibration procedures and collect data. |

| Tear-down people | dismantle set-ups, check the components for damage and then put the components into a stored state. This is the entry-level position for people who didn’t start in the equipment warehouse or transportation functions. |

Alternatively, the technicians can be divided by major discipline areas: physical, dimensional, electrical, RF, microwave and so on. But the principles are the same regardless of the equipment.

Metrology technicians perform investigation work in addition to calibrations. They also apply proven principles to known situations and evaluate unexpected or contradictory results.

Specific education in metrology was formerly limited to sub-professional work. Most of the branches of the US Military train ‘enlisted-grade’ technicians to meet their specific needs.

Large industrial organizations also develop people who demonstrate aptitude in testing functions. When this is combined with an engineering degree, it qualifies the person as a metrology engineer. Over the last 15 years, universities such as the University of North Carolina at Charlotte have created a specific curriculum in metrology engineering. In England, metrology was part of the fifth year of some undergraduate engineering programs.

Metrologists are people who perform metrology work at and above the technician levels.

The metrology and calibration work described above is always accompanied by documentation. The documentation can be divided into two types: one related to the task, and the other related the administrative program. Task documentation includes calibration procedures and the collected data. Administrative program documentation includes equipment identification data, 'calibration certificates’, calibration time interval information and 'as-found' or 'out-of-tolerance' notifications.

Administrative programs standardize metrology and calibration work and make it possible to independently verify that the work was performed. Generally, the administrative program is specific to the organization performing the work, and addresses customer requirements. General administrative program specifications created by industry groups, such as the ANS (ANSI) Z540 series, may also be covered in the administrative program. Other specifications created by the US Food and Drug Administration, US Federal Aviation Administration or other agencies supplement or replace ANS Z540 for work in their domains. Often administrative programs can be as complicated and detailed as the measurement work itself.

Standards

Standards are objects or ideas designated as authoritative for some accepted reason. Whatever value they possess is useful for comparison to unknowns for the purpose of establishing or confirming an assigned value based on the standard. The design of this comparison process for measurements is metrology. The execution of measurement comparisons for the purpose of establishing the relationship between a standard and some other measuring device is calibration.

The ideal standard is independently reproducible without uncertainty. This is what the creators of the “metre” length standard were attempting to do in the 19th century when they defined a metre as one ten-millionth of the distance from the equator to one of the Earth’s poles. It was later learned that the Earth’s surface is an unreliable basis for a standard, as the Earth is not spherical and it is constantly changing in shape. But the special alloy metre bars that were created and accepted in that time period standardized international length measurement until the 1950s. Careful calibrations allowed tolerances as small as 10 parts per million to be distributed and reproduced in metrology laboratories worldwide, regardless of whether the rest of the metric system was implemented and in spite of the shortfalls of the metre’s original basis.

Modern standards

Currently, five independent units of measure are internationally recognized: temperature interval, linear distance, electrical current, frequency and mass. Any measurement can be based on one or more of these measurement units. To supplement these five, two units of angle measurement that are also independent are recognized. For example, Ohm's law is a widely known concept in electrical study. Of the three units of measure involved, only current (ampere) is an independent unit. Voltage and resistance units are dependent on current units, as defined by Ohm's law.

Interested parties believe that eventually, standards organizations will define each of the independent units of measure in terms of the other four independent units. Length (metre) and time (second) are already connected this way. If an accurate time base is available, then a length standard can be reproduced without a metre bar artifact, using the known constant speed of light. Lesser known is the relationship between the luminance (candela) and current (ampere). The candela is defined in terms of the watt, which in turn derives from the ampere.

Non-commercial measurement details were once academic curiosities. However, engineering, manufacturing and ordinary living now routinely challenge the limits of measurement. Standards development follows the needs of technology. As a result, some units of measure have higher resolution than others. The second is reproducible to 1 part in 1014. As it became possible to measure time more precisely, solar time, believed to be a constant, proved to be very slightly irregular. This resulted in leap second adjustments to keep UTC synchronised with solar time.

The candela standard is difficult to recreate. An incandescent bulb design must be used as a secondary standard a supplementary standard, a transfer standard. These special candela standard bulbs recreate the candela when a specific amount of current is applied. Luminance (candela) can only be reproduced to 5% of reading despite having sensors that have accuracies of +/- 50 parts per million (0.005%) precision. This is due to the standard not being accurately reproducible.

Temperature (kelvin) is defined by agreed fixed points. These points are defined by the state changes of nearly pure materials, generally as they move from liquid to solid. Between these fixed points, standard platinum resistance thermometers (SPRTs), constructed in a specified manner, are used to interpolate temperature values. This mosaic of approaches produces measurement uncertainty—measurements that are not uniform over the entire temperature range. Temperature measurement is coordinated by the International Practical Temperature Scale, maintained by the BIPM.

Industry-specific standards

In addition to standards created by national and international standards organizations, many large and small industrial companies also define metrology standards and procedures to meet particular needs for technically and economically competitive manufacturing. These standards and procedures, while drawing on the national and international standards, also address issues of what specific instrument technology to use to measure each quantity, how often to measure each quantity, and which definition of each quantity to use for process control for a particular manufacturing and product specification. An industrial metrology standard includes a dynamic control plan (DCP, also known as a dimensional control plans for their product.

In industrial metrology, several issues beyond accuracy constrain the usability of metrology methods. These include:

- Speed with which measurements can be accomplished on parts or surfaces in the process of manufacturing, which must match the takt time of the production line

- Completeness with which the manufactured part can be measured, such as described in high-definition metrology

- Ability of the measurement mechanism to operate reliably in a manufacturing plant environment considering temperature, vibration, dust, and other hostile factors

- Ability of the measurement results, as presented, to be assimilated by manufacturing operators or automation in time to effectively control manufacturing process variables

- Total financial cost of measuring each part

National standards

Every country maintains its own metrology system.

United States

In the United States, the National Institute of Standards and Technology (NIST) plays the dual role of maintaining and furthering both commercial and scientific metrology. NIST does not enforce measurement accuracy directly.

The accuracy and traceability of commercial measurements is enforced per the laws of individual states. Commercial measurement generally involves any material sold by any unit of measure. Some intuitive or obvious measurement is generally exempted, such as selling cloth on a cutting table that has a yardstick fastened to it. All counting-based transactions are generally exempt also, but each state has its own rules, responding to the accumulated concerns of the state residents.

Commercial metrology is also known as "weights and measures" and is essential to commerce of any kind above the pure barter level. Every state maintains its own weights and measures functionality with traceability to the national standards maintained by NIST. Large states further divide this effort by county, where a "Sealer" or other appointee is responsible for the validity of most common commercial measurements such as mass balances (scales) in grocery stores and gasoline pump measurements of volume. The sealer's staff and agents make periodic inspections to verify compliance, maintaining the integrity of commercial measurements.

Depending on the specific state, other state government agencies can be involved. For example, electricity watt-hour meters and water delivery flow meters are commonly monitored by the state's "public utilities commission" who enforces the measurement tolerances and traceability to NIST through the utility providers. Highway State Police and the State Highway Department generally run the commercial truck weight measurement programs for safety purposes and to minimize the damage to road surfaces that overloaded trucks cause. Nearly all states license weighmasters, weighmistresses, scale calibrators and other specialists involved in commercial measuring equipment maintenance.

The term "commercial metrology" is also used to describe calibration laboratories that are not owned by the companies they serve.

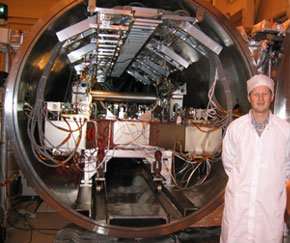

Scientific metrology addresses measurement phenomena not quantified in ordinary commerce, such as the test bed pictured at the beginning of the article. Calibration laboratories that serve scientific metrology are regulated as businesses only. They may choose to have their work accredited by voluntary certification organizations based on customer desires, but there is no requirement to do so. Irresolvable disputes involving scientific metrology are generally settled in the civil court systems. Some federal government entities like the Federal Communications Commission and the Environmental Protection Administration are considered final authority in their domains, rather than the NIST. Disputes involving only metrology issues with those organizations probably would not be heard in any court.

Historical development

Metrology has existed in some form or another since antiquity. Solomon said: "A false balance is an abomination to the Lord, but an accurate weight is his delight."[9] The earliest forms of metrology were simply arbitrary standards set up by regional or local authorities, often based on practical measures such as the length of an arm. The earliest examples of these standardized measures are length, time, and weight. These standards were established to facilitate commerce and record human activity.

Significant progress in metrology was made by various scientists, chemists, and physicists during the scientific revolution. With the advances in the sciences, the comparison of experiment to theory required a rational system of units, and something more closely resembling modern metrology began to come into being. The discovery of atoms, electricity, thermodynamics, and other fundamental scientific principles could be applied to standards of measurement, and many inventions made it easier to quantitatively or qualitatively assess physical properties, using the defined units of measurement established by science.

Metrology was thus one of the precursors to the Industrial Revolution, and was necessary for the implementation of mass production, equipment commonality, and assembly lines.

Modern metrology has its roots in the French Revolution, with the political motivation to harmonize units all over France and the concept of establishing units of measurement based on constants of nature, and thus making measurement units available "for all people, for all time". In this case deriving a unit of length from the dimensions of the Earth, and a unit of mass from a cube of water. The result was platinum standards for the metre and the kilogram established as the basis of the metric system on June 22, 1799. This further led to the creation of the Système International d'Unités, or the International System of Units. This system has gained unprecedented worldwide acceptance as definitions and standards of modern measurement units. Though not the official system of units of all nations, the definitions and specifications of SI are globally accepted and recognized. The SI is maintained under the auspices of the Metre Convention and its institutions, the General Conference on Weights and Measures, or CGPM, its executive branch the International Committee for Weights and Measures, or CIPM, and its technical institution the International Bureau of Weights and Measures, or BIPM.

As the authorities on SI, these organizations establish and promulgate the SI, with the ambition to service all. This includes introducing new units, such as the relatively new unit, the mole, to encompass metrology in chemistry. These units are then established and maintained through various agencies in each country, and establish a hierarchy of measurement standards that can be traced back to the established standard unit, a concept known as metrological traceability. The U.S. agencies holding this responsibility are the National Institute of Standards and Technology (NIST) and the American National Standards Institute (ANSI).

The development of standards also does involve individual and small group achievements. In 1893, Edward Weston (chemist) and his company perfected his Saturated Standard Cell design, which allowed the volt to be reproduced to 1 part in ten to the fourth power directly. This advance made a huge practical difference at a critical moment in the development of modern electrical devices. Groupings of saturated cells, called banks, can still be found in some metrology and calibration laboratories today. Edward Weston did not pursue patents for his cell design. By doing this, his superior design quickly replaced similar but inferior patented devices worldwide without much discussion.

Mechanisms

At the base of metrology is the definition, realisation and dissemination of units of measurement. Physical or chemical properties are quantised by assigning a property value in some multiple of a measurement unit.

The basic 'lineage' of measurement standards are:

- The definition of a unit, based on some physical constant, such as absolute zero, the freezing point of water, etc.; or an agreed-upon arbitrary standard.

- The realisation of the unit by experimental methods and the scaling into multiples and submultiples, by establishment of primary standards. In some cases an approximation is used, when the realisation of the units is less precise than other methods of generating a scale of the quantity in question. This is presently the situation for the electrical units in the SI, where voltage and resistance are defined in terms of the ampere, but are used in practice from realisations based on the Josephson effect and the quantised Hall effect.

- The transfer of traceability from the primary standards to secondary and working standards. This is achieved by calibration.

Theoretically, metrology, as the science of measurement, attempts to validate the data obtained from test equipment. Though metrology is the science of measurement, in practical applications, it is the enforcement, verification and validation of predefined standards for:[10]

| Criterion | Definition |

|---|---|

| Accuracy | Degree of exactness with which the final product corresponds to the measurement standard |

| Precision | Ability to produce a measurement consistently |

| Reliability | Consistency of accurate results over consecutive measurements over time |

| Traceability | Ongoing validations that the measurement of the final product conforms to the original standard of measurement |

These standards vary widely, but are often mandated by governments, agencies, and treaties such as the International Organization for Standardization, the Metre Convention, or the FDA. These agencies promulgate policies and regulations that standardize industries, countries, and streamline international trade, products, and measurements. Metrology is, at its core, an analysis of the uncertainty of individual measurements, and attempts to validate each measurement made with a given instrument, and the data obtained from it. The dissemination of traceability to consumers in society is often performed by a dedicated calibration laboratory with a recognized quality system in compliance with such standards. National laboratory accreditation schemes have been established to offer third-party assessment of such quality systems. A central requirement of these accreditations is documented traceability to national or international standards.

Some common standards include:

- ISO 17025:2005—General Requirements for Calibration Laboratories

- ISO 9000—Quality Systems Management

- ISO 14000—Environmental Management

- 21 CFR Part 210/211—FDA Regulations concerning GMP (Good Manufacturing Practices) Quality Systems

- 21 CFR Part 110—FDA Regulations concerning Food Industry GMP's.

Time and frequency metrology

This area of metrology studies components and their characteristics, especially

Laboratories

A measurement standards laboratory is a metrology laboratory that establishes standards for a country or organisation. National and international standards laboratories include:

- National Institute of Standards and Technology (NIST), United States, formerly the National Bureau of Standards

- National Measurement Institute, Australia

- National Physical Laboratory of India

- National Physical Laboratory (United Kingdom)

- Physikalisch-Technische Bundesanstalt, Germany

- Centre for Metrology and Accreditation (MIKES), Finland

- Korea Research Institute of Standards and Science (KRISS), Republic of Korea.

- Federal Institute of Metrology (METAS), Switzerland

- National Metrology Institute of Malaysia, formerly the National Metrology Laboratory

International organisations

- International Bureau of Weights and Measures, international body, headquartered in France, one of the bodies that governs SI

- Joint Committee for Guides in Metrology

- International Organization of Legal Metrology

- EURAMET

- WELMEC

See also

- Accuracy and precision

- Data analysis

- Dimensional metrology

- Geometric dimensioning and tolerancing

- Forensic metrology

- Historical metrology

- Length measurement

- Metrication

- Metrologia (academic journal)

- NCSL International

- Test method

- World Metrology Day

- Instrumentation

- International vocabulary of metrology

Notes

- ↑ "What is metrology?". BIPM. 2004. Retrieved 2011-12-01.

- ↑ "International vocabulary of metrology – Basic and general concepts and associated terms (VIM)" (PDF) (3rd ed.). Joint Committee for Guides in Metrology. 2012.

- 1 2 Czichos, Horst; Smith, Leslie, eds. (2011). Springer Handbook of Metrology and Testing (2nd ed.). 1.2.2 Categories of Metrology. ISBN 978-3-642-16640-2.

- ↑ Collège français de métrologie [French College of Metrology] (2006). Placko, Dominique, ed. Metrology in Industry – The Key for Quality (PDF). ISTE. 2.4.1 Scope of legal metrology. ISBN 978-1-905209-51-4.

... any application of metrology may fall under the scope of legal metrology if regulations are applicable to all measuring methods and instruments, and in particular if quality control is supervised by the state.

- ↑ "The BIPM key comparison database". BIPM. Retrieved 26 Sep 2013.

- ↑ International Vocabulary of Terms in Legal Metrology (PDF). Paris: OIML. 2000. p. 7. Archived from the original (PDF) on September 28, 2007.

- ↑ See "Metrological traceability". BIPM. Retrieved 2011-04-10.

- ↑ International vocabulary of metrology — basic and general concepts and associated terms (PDF) (3 ed.). Joint Committee on Guides for Metrology (JCGM). 2008.

- ↑ Bible, New Revised Standard Version, Proverbs 11, 1

- ↑ Fundamentals of Dimensional Metrology, Ted Busch, Wilkie Bros Foundation, Delmar Publishers, ISBN 0-8273-2127-9

References

- Forouhi, Rahim (2012). "Optical Metrology for thin films and OCD measurements" http://www.nandk.com/

- Baber, Zaheer (1996). The Science of Empire: Scientific Knowledge, Civilization, and Colonial Rule in India. State University of New York Press. ISBN 0-7914-2919-9.

- Organisation Internationale de Metrologie Legale. (2000), International Vocabulary of Terms in Legal Metrology, [Online] http://www.oiml.org/publications/V/V001-ef00.pdf. (Latest version draft can be downloaded at http://www.ncsli.org/vim/wg2_doc_N318_VIM_3rd_edition_2006-08-01%20(3).pdf)

- Bureau International des Poids et Mesures. (2005), "What is metrology", Copyright BIPM 2004, [Online] http://www.bipm.org/en/worldwide-metrology/.

- International Organization for Standardization. (2007), ISO Guide 99: International vocabulary of metrology—Basic and general concepts and associated terms (VIM), [Online] http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=45324

- Sarle, W. (1995), Measurement theory: Frequently asked questions, Copyright 1995 by Warren S. Sarle, Cary, NC, USA [Online] SAS Institute web pages: ftp://ftp.sas.com/pub/neural/measurement.faq

- Bureau International des Poids et Mesures. (2000), The International System of Units (SI), [Online] BIPM web pages: http://www.bipm.org/en/si/

- Bureau International des Poids et Mesures. (2000), The Convention of the Metre, [Online] BIPM web pages: http://www.bipm.org/en/convention/

- Melville, D.J. (2001). Sumerian metrological numeration systems, Mesopotamian Mathematics, [Online] St. Lawrence University web pages, http://it.stlawu.edu/%7Edmelvill/mesomath/sumerian.html

- National Institute of Standards and Technology. (1999), The NIST Reference of Constants, Units, and Uncertainty, [Online] NIST web pages: http://physics.nist.gov/cuu/index.html

- National Institute of Standards and Technology / Sematech. (n.d.). Engineering Statistics Handbook. [Online] NIST web pages: http://www.itl.nist.gov/div898/handbook/

- National Physical Laboratory, UK—National Measurement Laboratory—Metrology related resources including many free PDF downloads including Good Practice Guides: [Online] http://www.npl.co.uk/

- Franck Jedrzejewski, Histoire universelle de la mesure, Paris, Ellipses, 2002, ISBN 2-7298-1106-0. (in French)

- Ken Alder, "The Measure of All Things", Little, Brown 2002. (An historical account on the origin of the metric system, the meridian project).

- Kimothi, S. K., "The Uncertainty of Measurements: Physical and Chemical Metrology: Impact and Analysis", 2002, ISBN 0-87389-535-5

- Majcen N., Taylor P. (Editors): Practical examples on traceability, measurement uncertainty and validation in chemistry, Vol 1; ISBN 978-92-79-12021-3, 2010.

- Majcen N., Taylor P., T. Martisius (Editors): Practical examples on traceability, measurement uncertainty and validation in chemistry, Vol 2; ISBN 978-92-79-18998-2, 2011.

- R.B. da Silva, E. Bulska, B. Godlewska-Zylkiewicz, M. Hedrich, N. Majcen, B. Magnusson, S. Marincic, I. Papadakis, M. Patriarca, E. Vassileva, P. Taylor, Analytical measurement: measurement uncertainty and statistics;ISBN 978-92-79-23070-7, 2012.

External links

| Wikimedia Commons has media related to Metrology. |

- Measurement Uncertainties in Science and Technology, Springer 2005

- Bureau International des Poids et Mesures (BIPM)

- National Institute of Standards and Technology (NIST)

- National Physical Laboratory (NPL)

- Physikalisch-Technische Bundesanstalt (PTB)

- U.S. Naval Observatory

- National Conference of Standards Laboratories (NCSL)

- NCSL International

- International Organization for Standardization

- Presentation about Product Quality planning that includes a typical industry “Dimensional Control Plan”

- National Metrology Network of Chile

- National Metrology Laboratory of Malaysia

- UNC Charlotte Center for Precision Metrology

- National Metrology Laboratory of México

- Institute for Reference Materials and Measurements

- Metrology Equipment Listing

- LearningMeasure.com Metrology Training

- European Association of National Metrology Institutes (EURAMET)

- Training in Metrology in Chemistry (TrainMiC)

- Measurement Science in Chemistry