Isle of Wight gasification facility

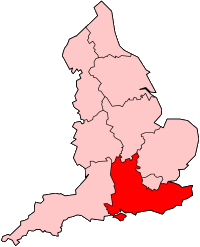

Coordinates: 50°42′18″N 1°20′06″W / 50.705°N 1.335°W The Isle of Wight gasification facility is a municipal waste treatment plant in southern England.[1] It entered the commissioning phase in autumn 2008.[2]

The facility has been funded as part of Defra's New Technologies Demonstrator Programme and is one of the first and only facilities in the United Kingdom to be classed as a gasification system employed for the combustion of refuse derived fuel originating from municipal waste. The plant is operated by Waste Gas Technology UK Ltd, part of the ENER·G group, and utilises the Energos technology; Energos is also part of the ENER·G group. The Energos system was retrofitted into a small conventional incinerator plant[3] and will combust an estimated 30,000 tonnes of refuse-derived fuel per year. The retrofit cost £10 million to commission, £2.7 million of which was funded by DEFRA.[4]

The plant is sited at Forest Road, Newport.

Temporary suspension of operation, 2010

Due to increased dioxin emission levels detected in March 2010 exceeding 8 times the legal limit,[5] operation was temporarily suspended spring 2010. The flue gas cleaning system of the old incinerator was reused in the retrofit, and ENER·G reported this system to be the cause of the problem.[6] Following modifications and several startup attempts, it has been operating again since October 2010.[7]

In June 2011, the Isle of Wight council decided to make radical efforts to lessen its dependence on the gasification facility with reference to its history of limited reliability.[8]

Energos technology

The Energos system includes a close coupled combustion stage which, as configured, uses all the syngas in the combustion stage. It is thus not able to produce syngas for external use and therefore sometimes categorized as two-stage combustion. The process enables improved control of the combustion to minimise the formation of combustion related emissions such as oxides of nitrogen (NOx), Carbon Monoxide (CO) and Total Organic Carbons (TOC). Operating plants achieve average annual NOx emissions of 25 – 30% of the EU limit using just process control and without the need for either Selective Non Catalytic Reduction (SNCR) or Selective Catalytic Reduction (SCR), whilst at the same time achieving very low CO and TOC emissions.

The energy in the combusted syngas is converted into steam. Energos plants produce steam at lower temperature and pressure than modern waste incinerators, and thus achieve low energy-efficiencies compared to incinerators. As a CHP or heat delivery plant, the cycle efficiency is approaching 85%. One such example is the recently constructed Sarpsborg 2 plant, which provides process steam to the Borregaard Chemical Plant, directly displacing heavy fuel oil.

The Isle of Wight plant debuts a new furnace design for the Energos process aimed at increased combustion efficiency, dust removal and enabling less interruptions and downtime than the earlier design[9]

See also

References

- ↑ Construction start for Isle of Wight incineration plant, www.letsrecycle.com, retrieved 18.09.07

- ↑ Island Gasification Plant Powers Up, Article in Island Pulse, 12 November 2008

- ↑ Green Lane Eco Park Community Meeting 25 January 2010

- ↑ Energy from Waste: Set to attract Investment from the Cleantech Investor website

- ↑ Energos Isle of Wight Plant Fails Dioxin and Furan Emissions Tests from the Say no to Green Lane Incinerator web site

- ↑ Energy Plant Suspends Waste Processing, Article in Island Pulse, 31 May 2010

- ↑ Isle of Wight gasification plant achieves compliance, letsrecycle.com, April 1., 2011

- ↑ Isle of Wight seeks to reduce use of 'unreliable' gasifier, letsrecycle.com, June 22., 2011

- ↑ MSW Spells Self-Sufficiency for Isle of Wight Residents, Article in Biomass Magazine, August 2009.

External links

- "Island to open gasification plant". BBC News. 16 May 2007. Retrieved 2009-10-14.