Herbert Akroyd Stuart

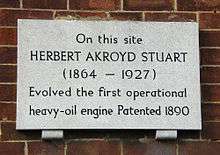

Herbert Akroyd-Stuart (28 January 1864, Halifax, Yorkshire, England – 19 February 1927, Halifax) was an English inventor who is noted for his invention of the hot bulb engine, or heavy oil engine.

Life

Akroyd-Stuart had lived in Australia in his early years. He was educated at Newbury Grammar School (now St. Bartholomew's School) and Finsbury Technical College on Cowper Street. He was the son of Charles Stuart, founder of the Bletchley Iron and Tinplate Works, and joined his father in the business in 1887.[1]

Oil engines

In 1885, Akroyd Stuart accidentally spilt paraffin oil (kerosene) into a pot of molten tin. The paraffin oil vaporised and caught fire when in contact with a paraffin lamp. This gave him an idea to pursue the possibility of using paraffin oil (very similar to modern-day diesel) for an engine, which unlike petrol would be difficult to be vaporised in a carburettor as its volatility is not sufficient to allow this.

His first prototype engines were built in 1886. In 1890, in collaboration with Charles Richard Binney, he filed Patent 7146 for Richard Hornsby and Sons of Grantham, Lincolnshire, England. The patent was entitled: "Improvements in Engines Operated by the Explosion of Mixtures of Combustible Vapour or Gas and Air".[2] One such engine was sold to Newport Sanitary Authority, but the compression ratio was too low to get it started from cold, and it needed a heat poultice to get it going.[3]

Hornsby-Akroyd engine

Akroyd-Stuart's engines were built from 26 June 1891 by Richard Hornsby and Sons as the Hornsby Akroyd Patent Oil Engine under licence and were first sold commercially on 8 July 1892. It was the first internal combustion engine to use a pressurised fuel injection system.[4]

The Hornsby-Akroyd engine used a comparatively low compression ratio, so that the temperature of the air compressed in the combustion chamber at the end of the compression stroke was not high enough to initiate combustion. Combustion instead took place in a separated combustion chamber, the "vaporizer" (also called the "hot bulb") mounted on the cylinder head, into which fuel was sprayed. It was connected to the cylinder by a narrow passage and was heated either by the cylinder's coolant or by exhaust gases while running; an external flame such as a blowtorch was used for starting. Self-ignition occurred from contact between the fuel-air mixture and the hot walls of the vaporizer.[5] By contracting the bulb to a very narrow neck where it attached to the cylinder, a high degree of turbulence was set up as the ignited gases flashed through the neck into the cylinder, where combustion was completed. As the engine's load increased, so did the temperature of the bulb, causing the ignition period to advance; to counteract pre-ignition, water was dripped into the air intake.[6]

Hot bulb engines were produced until the late 1920s, often being called "semi-diesels", even though they were not as efficient as compression ignition engines. They had the advantage of comparative simplicity, since they did not require the air compressor used by early Diesel engines; fuel was injected mechanically (solid injection) near the start of the compression stroke, at a much lower pressure than that of Diesel engines.[5]

Oil-engined locomotive

Richard Hornsby and Sons built the world's first oil-engined railway locomotive LACHESIS for the Royal Arsenal, Woolwich, England, in 1896. They also built the first compression-ignition powered automobile.

Oil engines outside the UK

- Sweden

Similar engines were built by Bolinder in Sweden and some of these still survive in canal boats.

- United States

Hot bulb engines were built in the USA by the De La Vergne Company of New York City, later the New York Refrigerating Company - inventing the modern refrigerator in 1930, who purchased a licence in 1893.

Patent dispute with Rudolf Diesel

The modern Diesel engine is a hybrid incorporating the features of direct (airless) injection and compression-ignition, both patented (No. 7146) as Improvements in Engines Operated by the Explosion of Mixtures of Combustible Vapour or Gas and Air by Akroyd-Stuart and Charles Richard Binney in May 1890.[2] Another patent (No. 15,994) was taken out on 8 October 1890, which details the working of a complete engine where air and fuel are introduced separately.

In 1890, Akroyd-Stuart patented the hot-bulb engine which had only about a 12% thermal efficiency. The reason for this, which he was not able to identify, was due to the lower pressures used (around 90 PSI[6]) as opposed to the Diesel engine's c. 500 PSI).

Rudolf Diesel patented the compression-ignition engine in 1892; however his injection system, where combustion was produced isobarically (the technique having been patented by George Brayton in 1874 for his carburettor), was not subsumed into later engines, Akroyd-Stuart's injection system with isochoric combustion developed at Hornsbys being preferred.

In 1892, Akroyd-Stuart patented a water-jacketed vaporiser to allow compression ratios to be increased. In the same year, Thomas Henry Barton (who later founded Barton Transport) at Hornsbys built a working high-compression version for experimental purposes, whereby the vaporiser was replaced with a cylinder head, therefore not relying on air being preheated, but by combustion through higher compression ratios. It ran for six hours - the first time automatic ignition was produced by compression alone.

On the other hand, Diesel understood thermodynamics and the theoretical and practical constraints on fuel efficiency. He knew that as much as 90% of the energy available in the fuel is wasted in a steam engine, and began to focus on designs that will achieve higher efficiency ratios. From 1893 to 1897, Rudolf Diesel continued to develop and improve his designs. He first experimented with a Carnot Cycle engine, and then developed his own approach. In his engine, fuel was injected at the end of compression and the fuel was ignited by the high temperature resulting from compression. This led to his design of the well-known high-compression prototype which was patented in 1897 in Germany and other countries, including the U.S. (U.S. Patent 542,846 and U.S. Patent 608,845).

Death

In 1900, he moved to Australia and set up a company Sanders & Stuart with his brother Charles, latterly moving back to Yorkshire, England. He died of throat cancer and was buried in All Souls church in Boothtown, Halifax.

The University of Nottingham has hosted the Akroyd-Stuart Memorial Lecture on occasional years in his memory since 1928. One was presented by Sir Frank Whittle in 1946. Akroyd Stuart had worked with Professor William Robinson in the late 19th century, who was professor of engineering from 1890 to 1924 at University College Nottingham.

Akroyd-Stuart also left money to the Institution of Mechanical Engineers, Royal Aeronautical Society and Institute of Marine Engineering, which provided for their respective bi-annual Akroyd-Stuart Prizes.

See also

Notes

- ↑ "Victoria Road". Bletchley Archaeological & Historical Society. Retrieved 2007-07-29.

- 1 2 "The Akroyd Oil Engine". Ray Hooley's - Ruston-Hornsby - Engine Pages. Retrieved 2007-07-29.

- ↑ "Diesel has come a long way but still doesn't get the tax breaks it deserves". The Scotsman, Scotland on Sunday. 2003-01-16. Retrieved 2007-07-29.

- ↑ Ransome-Wallis, Patrick (2001). Illustrated Encyclopedia of World Railway Locomotives. Courier Dover Publications. p. 27. ISBN 0-486-41247-4.

- 1 2 McNeil, Ian (1990). An Encyclopaedia of the History of Technology. Taylor & Francis. pp. 310–311. ISBN 0-415-01306-2.

- 1 2 Wrangham, D.A. (1956). The Theory & Practice of Heat Engines. Cambridge University Press. p. 664.

External links

- Biography

- Relation to the Ruston and Hornsby history.

- History of his Oil Engine at the Anson Engine Museum

- De La Vergne Oil Engine used for Marconi's first broadcast

- IMechE Herbert Akroyd Prize (sic)

- Immortalised by naming a range of bollards after him

- All Souls Church, Halifax

Patents

- US Patent 845140 Combustion Engine, dated 26 February 1907.

- US Patent 502837 Engine operated by the explosion of mixtures of gas or hydrocarbon vapor and air, dated 8 August 1893.

- US Patent 439702 Petroleum Engine or Motor, dated 4 November 1890.