Fischer–Speier esterification

| Fischer–Speier esterification | |

|---|---|

| Named after | Hermann Emil Fischer Arthur Speier |

| Reaction type | Coupling reaction |

| Identifiers | |

| Organic Chemistry Portal | fischer-esterification |

| RSC ontology ID | RXNO:0000167 |

Fischer esterification or Fischer–Speier esterification is a special type of esterification by refluxing a carboxylic acid and an alcohol in the presence of an acid catalyst. The reaction was first described by Emil Fischer and Arthur Speier in 1895.[1] Most carboxylic acids are suitable for the reaction, but the alcohol should generally be a primary or secondary alkyl. Tertiary alcohols are prone to elimination, and phenols are usually too unreactive to give useful yields. Commonly used catalysts for a Fischer esterification include sulfuric acid, tosylic acid, and Lewis acids such as scandium(III) triflate. For more valuable or sensitive substrates (for example, biomaterials), dicyclohexylcarbodiimide is often used. The reaction is often carried out without a solvent (particularly when a large reagent excess of alcohol is used) or in a non-polar solvent (e.g. toluene) to facilitate the Dean-Stark method.[2] Typical reaction times vary from 1–10 hours at temperatures of 60-110 °C.

Direct acylations of alcohols with carboxylic acids is preferred over acylations with anhydrides (poor atom economy) or acid chlorides (moisture sensitive). The main disadvantage of direct acylation is the unfavorable chemical equilibrium that must be remedied (e.g. by a large excess of one of the reagents), or by the removal of water (e.g. by using Dean-Stark distillation, anhydrous salts,[3] molecular sieves, or by using a stoichiometric quantity of acid catalyst).

Overview

Fischer esterification is an example of nucleophilic acyl substitution based on the electrophilicity of the carbonyl carbon and the nucleophilicity of an alcohol. However, carboxylic acids tend to be less reactive than esters as electrophiles. Additionally, in dilute neutral solutions they tend to be deprotonated anions (and thus unreactive as electrophiles). Though very kinetically slow without any catalysts (most esters are metastable), pure esters will tend to spontaneously hydrolyse in the presence of water, so when carried out "unaided", high yields for this reaction is quite unfavourable.

Several steps can be taken to turn this unfavourable reaction into a favourable one.[2]

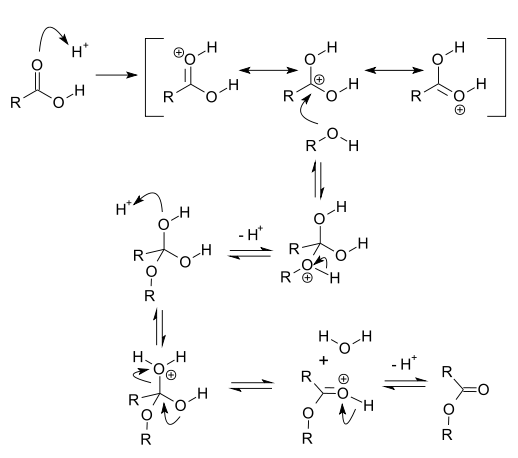

The reaction mechanism for this reaction has several steps:

- Proton transfer from acid catalyst to carbonyl oxygen increases electrophilicity of carbonyl carbon.

- The carbonyl carbon is then attacked by the nucleophilic oxygen atom of the alcohol

- Proton transfer from the oxonium ion to a second molecule of the alcohol gives an activated complex

- Protonation of one of the hydroxyl groups of the activated complex gives a new oxonium ion.

- Loss of water from this oxonium ion and subsequent deprotonation gives the ester.

A generic mechanism for an acid Fischer esterification is shown below.

Advantages and Disadvantages

Advantages

The primary advantages of Fischer esterification compared to other esterification processes are based on its relative simplicity. Straightforward acidic conditions can be used if acid-sensitive functional groups are not an issue; sulfuric acid can be used; softer acids can be used with a tradeoff of longer reaction times. Because the reagents used are "direct," there is less environmental impact in terms of waste products and harmfulness of the reagents. Alkyl halides are potential greenhouse gases or ozone depletors and possible ecological poisons. Acid chlorides evolve hydrogen chloride gas upon contact with atmospheric moisture, are corrosive, react vigorously with water and other nucleophiles (sometimes dangerously); they are easily quenched by other nucleophiles besides the desired alcohol; their most common synthesis routes involve the evolution of toxic carbon monoxide or sulfur dioxide gases (depending on the synthesis process used).

Acid anhydrides are more reactive than esters because the leaving group is a carboxylate anion—a better leaving group than an alkoxide anion because their negative charge is more delocalised. However, such routes generally result in poor atom economy. For example, in reacting ethanol with acetic anhydride, ethyl acetate forms and acetic acid is kicked out as a leaving group, which is considerably less reactive than an acid anhydride and will be left as a byproduct (in a wasteful 1:1 ratio with the ester product) if product is collected immediately. If conditions are acidic enough, the acetic acid can be further reacted via the Fischer esterification pathway, but at a much slower pace. However, in many carefully designed syntheses, reagents can be designed such that acid anhydrides are generated in situ and carboxylic acid byproducts are reactivated, and Fischer esterification routes are not necessarily mutually exclusive with acetic anhydride routes. (Examples of this include the common undergraduate organic lab experiment involving the acetylation of salicylic acid to yield aspirin.)

Fischer esterification is primarily a thermodynamically-controlled process: because of its slowness, the most stable ester tends to be the major product. This can be a desirable trait if there are multiple reaction sites and side product esters to be avoided. In contrast, rapid reactions involving acid anhydrides or acid chlorides are often kinetically-controlled.

Disadvantages

The primary disadvantages of Fischer esterification routes are its thermodynamic reversibility and relatively slow reaction rates—often on the scale of several hours to years, depending on the reaction conditions. Workarounds to this can be inconvenient if there are other functional groups sensitive to strong acid, in which case other catalytic acids may be chosen. If the product ester has a lower boiling point than either water or the reagents, the product may be distilled rather than water; this is common as esters with no protic functional groups tend to have lower boiling points than their protic parent reagents. Purification and extraction are easier if the ester product can be distilled away from the reagents and byproducts, but reaction rate can be slowed because overall reaction temperature can be limited in this scenario. A more inconvenient scenario is if the reagents have a lower boiling point than either the ester product or water, in which case the reaction mixture must be capped and refluxed and a large excess of starting material added. In this case anhydrous salts, such as Copper(II) sulfate or Potassium pyrosulfate, can also be added to sequester the water by forming hydrates, shifting the equilibrium toward ester products.[3] These hydrated salts are then decanted prior to the final workup.

Examples in alcoholic beverages

The natural esterification that takes place in wines and other alcoholic beverages during the aging process is an example of acid-catalysed esterification. Over time, the acidity of the acetic acid and tannins in an aging wine will catalytically protonate other organic acids (including acetic acid itself), encouraging ethanol to react as a nucleophile. As a result, ethyl acetate—the ester of ethanol and acetic acid—is the most abundant ester in wines. Other combinations of organic alcohols (such as phenol-containing compounds) and organic acids lead to a variety of different esters in wines, contributing to their different flavours, smells and tastes. Of course, when compared to sulfuric acid conditions, the acid conditions in a wine are mild, so yield is low (often in tenths or hundredths of a percentage point by volume) and take years for ester to accumulate.

Variations

Tetrabutylammonium tribromide (TBATB) can serve as an effective but unconventional catalyst for this reaction.[4] It is believed that hydrobromic acid released by TBATB protonates the alcohol rather than the carboxylic acid, making the carboxylate the actual nucleophile. This would be a reversal of the standard esterification mechanism. An example of this method is the acylation 3-phenylpropanol using glacial acetic acid and TBATB. The reaction generates the ester in 15 minutes in a 95% yield without the need to remove water.

See also

- Fischer glycosidation - the coupling of an alcohol and a sugar

References

- ↑ Emil Fischer, Arthur Speier (1895). "Darstellung der Ester". Chemische Berichte. 28: 3252–3258. doi:10.1002/cber.189502803176.

- 1 2 Furniss, Brian; Hannaford, Antony; Smith, Peter; Tatchell, Austin (1996). Vogel's Textbook of Practical Organic Chemistry 5th Ed. London: Longman Science & Technical. pp. 695–697 & 699–704. ISBN 9780582462366.

- 1 2 Tingle, J. Bishop (1906). "Reports: Esterification". American Chemical Journal. 35: 368–369. Retrieved 19 January 2016.

- ↑ Tetrabutylammonium tribromide mediated condensation of carboxylic acids with alcohols Sarala Naik, Veerababurao Kavala, Rangam Gopinath, and Bhisma K. Patel Arkivoc 2006 (i) 119-127 Online Article