Falcon 9 v1.1

Launch of the 10th Falcon 9 v1.1 with the Deep Space Climate Observatory on 11 February 2015. This rocket was equipped with landing legs and grid fins.[1] | |

| Function | Orbital medium-lift launch vehicle |

|---|---|

| Manufacturer | SpaceX |

| Country of origin | United States |

| Cost per launch | $56.5M (2013) – 61.2M (2015)[2] |

| Size | |

| Height | 68.4 m (224 ft)[3] |

| Diameter | 3.66 m (12.0 ft)[3] |

| Mass | 505,846 kg (1,115,200 lb)[3] |

| Stages | 2 |

| Capacity | |

| Payload to LEO (28.5°) |

13,150 kg (28,990 lb)[3] 10,886 kg (24,000 lb) (PAF structural limitation)[4] |

| Payload to GTO (27°) | 4,850 kg (10,690 lb)[3] |

| Associated rockets | |

| Family | Falcon 9 |

| Derivatives | Falcon 9 Full Thrust |

| Comparable | |

| Launch history | |

| Status | Retired |

| Launch sites | |

| Total launches | 15 |

| Successes | 14 |

| Failures | 1 |

| Landings | 0 / 3 attempts |

| First flight | 29 September 2013[5] |

| Last flight | 17 January 2016 |

| Notable payloads | Dragon, DSCOVR |

| First stage | |

| Engines | 9 Merlin 1D |

| Thrust |

Sea level: 5,885 kN (1,323,000 lbf)[3] Vacuum: 6,672 kN (1,500,000 lbf)[3] |

| Specific impulse |

Sea level: 282 seconds[6] Vacuum: 311 seconds[6] |

| Burn time | 180 seconds[3] |

| Fuel | LOX / RP-1 |

| Second stage | |

| Engines | 1 Merlin 1D Vacuum |

| Thrust | 716 kN (161,000 lbf)[7] |

| Specific impulse | 340 seconds[3] |

| Burn time | 375 seconds[3] |

| Fuel | LOX / RP-1 |

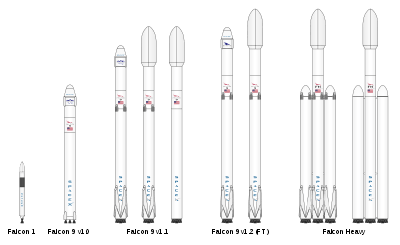

Falcon 9 v1.1 is the second version of SpaceX's Falcon 9 orbital launch vehicle. The rocket was developed in 2011–2013, made its maiden launch in September 2013,[8] and its final flight in January 2016.[9] The Falcon 9 rocket was fully designed, manufactured, and operated by SpaceX. Following the second Commercial Resupply Services (CRS) launch, the initial version Falcon 9 v1.0 was retired from use and replaced by the v1.1 version.

Falcon 9 v1.1 is a significant evolution from Falcon 9 v1.0, with 60 percent more thrust and weight. Its maiden flight carried out a demonstration mission with the CASSIOPE satellite on 29 September 2013, the sixth overall launch of any Falcon 9.[10]

Both stages of the two-stage-to-orbit vehicle use liquid oxygen (LOX) and rocket-grade kerosene (RP-1) propellants.[11] The Falcon 9 v1.1 can lift payloads of 13,150 kilograms (28,990 lb) to low Earth orbit, and 4,850 kilograms (10,690 lb) to geostationary transfer orbit,[2] which places the Falcon 9 design in the medium-lift range of launch systems.[12]

Beginning in April 2014, the Dragon capsules were propelled by Falcon 9 v1.1 to deliver cargo to the International Space Station under the Commercial Resupply Services contract with NASA.[13] This version was also intended to ferry astronauts to the ISS under a NASA Commercial Crew Development contract signed in September 2014[14] but those missions will now be carried out with the upgraded Falcon 9 Full Thrust version, first flown in December 2015.

Falcon 9 v1.1 was notable for pioneering the development of reusable rockets, whereby SpaceX gradually refined technologies for first-stage boostback, atmospheric re-entry, controlled descent and eventual propulsive landing. This last goal was achieved on the first flight of the successor variant Falcon 9 Full Thrust, after several close calls with Falcon 9 v1.1.

.jpg)

Design

The base Falcon 9 v1.1 is a two-stage, LOX/RP-1–powered launch vehicle.[11]

Changes from Falcon 9 v1.0

The Falcon 9 v1.1 ELV is a 60 percent heavier rocket with 60 percent more thrust than the v1.0 version of the Falcon 9.[15] It includes realigned first-stage engines[16] and 60 percent longer fuel tanks, making it more susceptible to bending during flight.[15] The engines have been upgraded to the more powerful Merlin 1D engines. These improvements increase the payload capability to LEO from 10,454 kilograms (23,047 lb)[17] to 13,150 kilograms (28,990 lb).[2] The stage separation system has been redesigned and reduces the number of attachment points from twelve to three,[15] and the vehicle has upgraded avionics and software as well.[15]

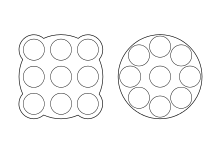

The v1.1 booster version arranges the engines in a structural form SpaceX calls Octaweb, aimed at streamlining the manufacturing process.[18] Later v1.1 vehicles include four extensible landing legs,[19] used in the controlled-descent test program.[20][21]

Following the first launch of the Falcon 9 v1.1 in September 2013, which experienced a post-mission second-stage engine restart failure, the second-stage igniter propellant lines were insulated to better support in-space restart following long coast phases for orbital trajectory maneuvers.[22]

Falcon 9 Flight 6 was the first launch of the Falcon 9 configured with a jettisonable payload fairing.[23]

First stage

The Falcon 9 v1.1 uses a first stage powered by nine Merlin 1D engines.[24][25] Development testing of the v1.1 Falcon 9 first stage was completed in July 2013.[26][27]

The v1.1 first stage has a total sea-level thrust at liftoff of 5,885 kilonewtons (1,323,000 lbf), with the nine engines burning for a nominal 180 seconds, while stage thrust rises to 6,672 kilonewtons (1,500,000 lbf) as the booster climbs out of the atmosphere.[28] The nine first-stage engines are arranged in a structural form SpaceX calls Octaweb. This change from the v1.0 Falcon 9's square arrangement is aimed at streamlining the manufacturing process.[18]

As part of SpaceX's efforts to develop a reuseable launch system, selected first stages include four extensible landing legs[19] and grid fins to control descent. Fins were first tested on the F9R Dev-1 reusable test vehicle.[29] Grid fins were implemented on the Falcon 9 v1.1 on the CRS-5 mission,[30] but ran out of hydraulic fluid before a planned landing.[31]

SpaceX ultimately intends to produce both Reusable Falcon 9 and Reusable Falcon Heavy launch vehicles with full vertical-landing capability.[20][21] Initial atmospheric testing of prototype vehicles is being conducted on the Grasshopper experimental technology-demonstrator reusable launch vehicle (RLV), in addition to the booster controlled-descent and landing tests described above.[32]

The v1.1 first stage uses a pyrophoric mixture of triethylaluminium-triethylborane (TEA-TEB) as a first-stage ignitor, the same as was used in the v1.0 version.[33]

Like the Falcon 9 v1.0 and the Saturn series from the Apollo program, the presence of multiple first-stage engines can allow for mission completion even if one of the first-stage engines fails mid-flight.[34][35]

The main propellant supply tubes from the RP-1 and liquid oxygen tanks to the nine engines on the first stage are 10 cm (4 in) in diameter.[36]

Second stage

The upper stage is powered by a single Merlin 1D engine modified for vacuum operation.[37]

The interstage, which connects the upper and lower stage for Falcon 9, is a carbon fiber aluminum core composite structure.[38] Separation collets and a pneumatic pusher system separate the stages.[39] The Falcon 9 tank walls and domes are made from aluminium-lithium alloy.[40] SpaceX uses an all-friction stir welded tank, a technique which minimizes manufacturing defects and reduces cost, according to a NASA spokesperson.[41] The second-stage tank of Falcon 9 is simply a shorter version of the first-stage tank and uses most of the same tooling, material and manufacturing techniques. This saves money during vehicle production.[34]

Payload fairing

The fairing design was completed by SpaceX, with production of the 13 m (43 ft)-long, 5.2 m (17 ft)-diameter payload fairing in Hawthorne, California.[42]

Testing of the new fairing design was completed at NASA's Plum Brook Station facility in spring 2013 where acoustic shock, mechanical vibration, and electromagnetic electrostatic discharge conditions were simulated. Tests were done on a full-size test article in vacuum chamber. SpaceX paid NASA US$581,300 to lease test time in the $150M NASA simulation chamber facility.[43]

The first flight of a Falcon 9 v1.1 (CASSIOPE, September 2013) was the first launch of the Falcon 9 v1.1 as well as the Falcon 9 family configured with a payload fairing. The fairing separated without incident during the launch of CASSIOPE as well as the two subsequent GTO insertion missions.[43] In Dragon missions, the capsule protects any small satellites, negating the need for a fairing.[44]

Control

SpaceX uses multiple redundant flight computers in a fault-tolerant design. Each Merlin engine is controlled by three voting computers, each of which has two physical processors that constantly check each other. The software runs on Linux and is written in C++.[45]

For flexibility, commercial off-the-shelf parts and system-wide "radiation-tolerant" design are used instead of rad-hardened parts.[45] Falcon 9 v1.1 continues to utilize the triple redundant flight computers and inertial navigation—with GPS overlay for additional orbit insertion accuracy—that were originally used in the Falcon 9 v1.0.[34]

Falcon 9 Full Thrust

In 2015, SpaceX made a number of modifications to the existing Falcon 9 v1.1. The new rocket was known internally as Falcon 9 Full Thrust,[46] and is also known as Falcon 9 v1.2, Enhanced Falcon 9, Full-Performance Falcon 9,[47] and Falcon 9 Upgrade.[48]

A principal objective of the new design was to facilitate booster reusability for a larger range of missions, including delivery of large commsats to geosynchronous orbit.[49]

Modifications in the upgraded version include:

- liquid oxygen subcooled to −340 °F (−206.7 °C; 66.5 K) and RP-1 cooled to 20 °F (−7 °C; 266 K)[50] for density (allowing more fuel and oxidizer to be stored in a given tank volume, as well as increasing the propellant mass flow through the turbopumps increasing thrust)

- upgraded structure in the first stage[48][51]

- longer second stage propellant tanks[48]

- longer and stronger interstage, housing the second stage engine nozzle, grid fins, and attitude thrusters[48][51]

- center pusher added for stage separation[48]

- design evolution of the grid fins[48][51]

- modified Octaweb[48]

- upgraded landing legs[48][51]

- Merlin 1D engine thrust increased[48] to the full-thrust variant of the Merlin 1D, taking advantage of the denser propellants achieved by subcooling.

- Merlin 1D vacuum thrust increased by subcooling the propellants.[48] The new second-stage engine was optimized for higher performance in vacuum through modifications such as a larger exhaust nozzle and an improved attitude control system.[52][53]

- several small mass-reduction efforts.[54]

The modified design gained an additional 1.2 meters of height, stretching to exactly 70 meters including payload fairing,[55] while gaining an overall performance increase of 33 percent.[48] The new first-stage engine has a much increased thrust-to-weight ratio.[53]

The full-thrust first stage booster could reach low Earth orbit as a single-stage-to-orbit if it is not carrying the upper stage and a heavy satellite.[56]

SpaceX President Gwynne Shotwell explained in March 2015 that the new design would result in streamlined production as well as improved performance:[57]

So, we got the higher thrust engines, finished development on that, we're in [qualification testing]. What we're also doing is modifying the structure a little bit. I want to be building only two versions, or two cores in my factory, any more than that would not be great from a customer perspective. It's about a 30% increase in performance, maybe a little more. What it does is it allows us to land the first stage for GTO missions on the drone ship.[47]

According to a SpaceX statement, Falcon 9 Full Thrust would likely not require a recertification to launch for United States government contracts. Shotwell stated that "It is an iterative process [with the agencies]" and that "It will become quicker and quicker to certify new versions of the vehicle."[58]

SES S.A., a satellite owner and operator, announced plans in February 2015 to launch its SES-9 satellite on the first flight of the Falcon 9 Full Thrust.[59] In the event, SpaceX elected to launch SES-9 on the second flight of the Falcon 9 Full Thrust and to launch Orbcomm OG2's second constellation on the first flight. As Chris Bergin of NASASpaceFlight explained, SES-9 required a more complicated second-stage burn profile involving one restart of the second-stage engine, while the Orbcomm mission would "allow for the Second Stage to conduct additional testing ahead of the more taxing SES-9 mission."[60]

The upgraded first stage began acceptance testing at SpaceX's McGregor facility in September 2015. The first of two static fire tests was completed on 21 September 2015 and included the subcooled propellant and the improved Merlin 1D engines.[61] The rocket reached full throttle during the static fire and was scheduled for launch no earlier than 17 November 2015.[62]

Falcon 9 Full Thrust completed its maiden flight on 21 December 2015, carrying an Orbcomm 11-satellite payload to orbit and landing the rocket's first stage intact at SpaceX's Landing Zone 1 at Cape Canaveral.[63] The second mission, Falcon 9 Flight 22 carrying SES-9, was completed on 4 March 2016.

Development and production

A test of the ignition system for the Falcon 9 v1.1 first stage was conducted in April 2013.[64] On 1 June 2013, a ten-second firing of the Falcon 9 v1.1 first stage occurred; a full-duration, 3-minute firing was expected a few days later.[65][66]

By September 2013, SpaceX total manufacturing space had increased to nearly 1,000,000 square feet (93,000 m2) and the factory had been configured to achieve a production rate of up to 40 rocket cores per year, for both the Falcon 9 v1.1 and the tri-core Falcon Heavy.[67] The November 2013 production rate for Falcon 9 vehicles was one per month. The company stated that this would increase to 18 per year in mid-2014, and would be 24 launch vehicles per year by the end of 2014.[22]

As launch manifest and launch rate increases in 2014–2016, SpaceX is looking to increase their launch processing by building dual-track parallel launch processes at the launch facility. As of March 2014, they projected that they would have this in operation sometime in 2015, and were aiming for a 2015 launch pace of about two launches per month.[68]

Other launcher versions

There are three versions of the Falcon 9. The original Falcon 9 flew five successful orbital launches in 2010–2013, all carrying the Dragon spacecraft or a test version of the spacecraft.[23]

The Falcon 9 v1.1 is a 60 percent heavier rocket with 60 percent more thrust than the v1.0 version of the Falcon 9.[15] It includes realigned first-stage engines[16] and 60 percent longer fuel tanks. The engines themselves were upgraded to the more powerful Merlin 1D. These improvements have increased the payload capability from 9,000 kilograms (20,000 lb) on the Falcon 9 v1.0 to 13,150 kilograms (28,990 lb).[2] The stage separation system was redesigned and reduced the number of attachment points from twelve to three.[15] The avionics and software have been upgraded in the v1.1 version as well.[15] The v1.1 first stage will also be used as side boosters on the Falcon Heavy launch vehicle.[69]

A third version of the rocket—Falcon 9 Full Thrust—was developed in 2014–2015 and made its maiden flight in December 2015. Originally called the Reusable Falcon 9 or Falcon 9-R, the Falcon 9 Full Thrust is a modified reusable variant of the Falcon 9 family with capabilities that exceed the Falcon 9 v1.1, including the ability to "land the first stage for GTO missions on the drone ship"[47][57] The rocket was designed using systems and software technology that had been developed as part of the SpaceX reusable launch system development program, a private initiative by SpaceX to facilitate rapid reusability of both the first–and in the long term, second—stages of SpaceX launch vehicles.[70] Various technologies were tested on the Grasshopper technology demonstrator, as well as several flights of the Falcon 9 v1.1 on which post-mission booster controlled-descent tests were being conducted.[71]

Reusability concept

The Falcon 9 v1.1 includes several aspects of reusable launch vehicle technology included in its design, as of the initial v1.1 launch in September 2013 (throttleable and restartable engines on the first stage, a first-stage tank design that can structurally accommodate the future addition of landing legs, etc.). The Falcon 9 v1.1's launch occurred two years after SpaceX committed to a privately funded development program with the goal to obtain full and rapid reusability of both stages of the launch vehicle.[72]

Design was complete on the system for "bringing the rocket back to launchpad using only thrusters" in February 2012.[73] The reusable launch system technology is being considered for both the Falcon 9 and the Falcon Heavy, and is considered particularly well suited to the Falcon Heavy where the two outer cores separate from the rocket much earlier in the flight profile, and are therefore moving at slower velocity at stage separation.[73]

A reusable first stage is now being flight tested by SpaceX with the suborbital Grasshopper rocket.[74] By April 2013, a low-altitude, low-speed demonstration test vehicle, Grasshopper v1.0, had made seven VTVL test flights from late-2012 through August 2013, including a 61-second hover flight to an altitude of 250 metres (820 ft).

In March 2013, SpaceX announced that, beginning with the first flight of the stretch version of the Falcon 9 launch vehicle (Falcon 9 v1.1)—which flew in September 2013—every first stage would be instrumented and equipped as a controlled descent test vehicle. SpaceX intends to do propulsive-return over-water tests and "will continue doing such tests until they can do a return to the launch site and a powered landing. ... [They] expect several failures before they 'learn how to do it right.'"[20] SpaceX completed multiple water landings that were successful and they now plan to land the first stage of the flight CRS-5 on an Autonomous drone port in the ocean.[21]

Photos of the first test of the restartable ignition system for the reusable Falcon 9—the Falcon 9-R— nine-engine v1.1 circular- engine configuration were released in April 2013.[64]

In March 2014, SpaceX announced that GTO payload of the future reusable Falcon 9 (F9-R), with only the booster reused, would be approximately 3,500 kg (7,700 lb).[54]

Post-mission test flights and landing attempts

Several missions of Falcon 9 v1.1 were followed by post-mission test flights calling for the first-stage booster to execute a flip around maneuver, a boostback burn to reduce the rocket's horizontal velocity, a re-entry burn to mitigate atmospheric damage at hypersonic speed, a controlled atmospheric descent with autonomous guidance to the target and finally a landing burn to cut vertical velocity to zero just before reaching the ocean or landing pad. SpaceX announced the test program in March 2013, and their intention to continue to conduct such tests until they can return to the launch site and perform a powered landing.[20]

The first stage of Falcon 9 Flight 6 performed the first test of a controlled descent and propulsive landing over water on 29 September 2013.[11] Although not a complete success, the stage was able to change direction and make a controlled entry into the atmosphere.[11] During the final landing burn, the ACS thrusters could not overcome an aerodynamically induced spin, and centrifugal force deprived the landing engine of fuel leading to early engine shutdown and a hard splashdown which destroyed the first stage. Pieces of wreckage were recovered for further study.[11]

The next test, using the first stage from SpaceX CRS-3, led to a successful soft landing in the ocean, however the booster presumably broke up in heavy seas before it could be recovered.[75]

After further ocean landing tests, the first stage of the CRS-5 launch vehicle attempted to land on a floating platform, the autonomous spaceport drone ship, in January 2015. The rocket guided itself to the ship successfully but landed too hard for survival.[76] The first stage of the CRS-6 mission managed a soft landing on the platform; however, excess lateral velocity caused it to quickly tip over and explode.[77] SpaceX CEO Elon Musk indicated that a throttle valve for the engine was stuck and did not respond quickly enough to achieve a smooth landing.[78]

Falcon 9 v1.1 was never successfully recovered or reused until its retirement. However the test program continued with Falcon 9 Full Thrust flights, which achieved both the first ground landing in December 2015 and the first ship landing in April 2016.

Launch sites

Falcon 9 v1.1 rockets were launched from both Launch Complex 40 at Cape Canaveral Air Force Station and Launch Complex 4E at Vandenberg Air Force Base. The Vandenberg site was used for both the v1.1 maiden flight on 29 September 2013[11] and its last mission on 17 January 2016.

Additional launch sites at Kennedy Space Center Launch Complex 39 pad A and Boca Chica, South Texas will launch the rocket's successor variants Falcon 9 Full Thrust and Falcon Heavy.

Launch prices

As of October 2015, the Falcon 9 v1.1 commercial launch price was US$61.2 million (up from US$56.5 million in October 2013)[2] competing for commercial launches in an increasingly competitive market.[79]

NASA resupply missions to the ISS—which include the provision of the space capsule payload, a new Dragon cargo spacecraft for each flight—have an average price of $133 million.[80] The first twelve cargo transport flights contracted to NASA were done at one time, so no price change is reflected for the v1.1 launches as opposed to the v1.0 launches. The contract was for a specific amount of cargo carried to, and returned from, the Space Station over a fixed number of flights.

SpaceX stated that due to mission assurance process costs, launches for the U.S. military would be priced about 50% more than commercial launches, so a Falcon 9 launch would sell for about $90 million to the US government, compared to an average cost to the US government of nearly $400 million for current non-SpaceX launches.[81]

Secondary payload services

Falcon 9 payload services include secondary and tertiary payload connection via an ESPA-ring, the same interstage adapter first utilized for launching secondary payloads on US DoD missions that utilize the Evolved Expendable Launch Vehicles (EELV) Atlas V and Delta IV. This enables secondary and even tertiary missions with minimal impact to the original mission. As of 2011, SpaceX announced pricing for ESPA-compatible payloads on the Falcon 9.[82]

Launch history

The first launch of the substantially upgraded Falcon 9 v1.1 vehicle successfully flew on 29 September 2013.[11][83]

The maiden Falcon 9 v1.1 launch included a number of "firsts":[5][84]

- First use of the upgraded Merlin 1D engines, generating approximately 56 percent more sea-level thrust than the Merlin 1C engines used on all previous Falcon 9 vehicles.[23]

- First use of the significantly longer first stage and second stage, which holds the additional propellant for the more powerful engines.[23]

- The nine Merlin 1D engines on the first stage are arranged in an octagonal pattern with eight engines in a circle and the ninth in the center.[18]

- First launch from SpaceX's new west coast launch facility, Space Launch Complex 4, at Vandenberg Air Force Base, California, and also the first launch over the Pacific ocean using the facilities of the Pacific test range.[85]

- First Falcon 9 launch to carry a satellite payload for a commercial customer, and also the first non-CRS mission. Each prior Falcon 9 launch was of a Dragon capsule or a Dragon-shaped test article, although SpaceX has previously successfully launched and deployed a satellite on the Falcon 1, Flight 5 mission.[23]

- First Falcon 9 launch to have a jettisonable payload fairing, which introduced the risk of an additional separation event.[23]

SpaceX conducted the fifteenth and final flight of the Falcon 9 v1.1 on 17 January 2016. Fourteen of those fifteen launches have successfully delivered their primary payloads to either Low Earth orbit or Geosynchronous Transfer Orbit.

Accidents and incidents

The only failed mission of the Falcon 9 v1.1 was SpaceX CRS-7, which was lost during its first stage operation, due to an overpressure event in the second stage oxygen tank.[86]

See also

- Falcon Heavy

- Falcon (rocket family)

- SpaceX Dragon and Dragon V2

- Comparison of orbital launch systems

- List of Falcon 9 and Falcon Heavy launches

References

- ↑ Graham, William (11 February 2015). "SpaceX Falcon 9 successfully launches the DSCOVR spacecraft". NASASpaceflight. Retrieved 24 October 2015.

- 1 2 3 4 5 "Capabilities & Services". SpaceX. Archived from the original on 7 October 2013. Retrieved 28 September 2013.

- 1 2 3 4 5 6 7 8 9 10 "Falcon 9". SpaceX. Archived from the original on 5 August 2014.

- ↑ "Falcon 9 Launch Vehicle Payload User's Guide" (PDF). 21 October 2015. Retrieved 29 November 2015.

SpaceX uses one of two PAFs on the launch vehicle, based on payload mass. The light PAF can accommodate payloads weighing up to 3,453 kg (7,612 lb), while the heavy PAF can accommodate up to 10,886 kg (24,000 lb). Payloads must comply with the mass properties limitations given in Figure 3-2.

- 1 2 Graham, Will. "SpaceX successfully launches debut Falcon 9 v1.1". NASASpaceFlight. Retrieved 29 September 2013.

- 1 2 "Falcon 9". SpaceX. Archived from the original on 1 May 2013. Retrieved 29 September 2013.

- ↑ "Merlin Engines". SpaceX. 26 March 2013. Archived from the original on 11 August 2014.

- ↑ "SpaceX Falcon 9 v1.1 Data Sheet". Space Launch Report. Retrieved 24 October 2015.

- ↑ Graham, William (17 January 2016). "SpaceX Falcon 9 v1.1 set for Jason-3 launch". NASASpaceFlight.com. NASASpaceFlight.com. Retrieved 17 January 2016.

- ↑ "SpaceX Falcon 9 rocket launch in California". CBS News. Retrieved 29 September 2013.

- 1 2 3 4 5 6 7 Graham, William (29 September 2013). "SpaceX successfully launches debut Falcon 9 v1.1". NASAspaceflight.com. Archived from the original on 29 September 2013. Retrieved 29 September 2013.

- ↑ NASA Space Technology Roadmaps - Launch Propulsion Systems, p.11: "Small: 0-2t payloads, Medium: 2-20t payloads, Heavy: 20-50t payloads, Super Heavy: >50t payloads"

- ↑ Graham, William (18 April 2014). "SpaceX Falcon 9 successfully launches CRS-3 Dragon". NASASpaceFlight. Retrieved 24 October 2015.

- ↑ Foust, Jeff (19 September 2014). "NASA Commercial Crew Awards Leave Unanswered Questions". Space News. Retrieved 21 September 2014.

“We basically awarded based on the proposals that we were given,” Kathy Lueders, NASA commercial crew program manager, said in a teleconference with reporters after the announcement. “Both contracts have the same requirements. The companies proposed the value within which they were able to do the work, and the government accepted that.”

- 1 2 3 4 5 6 7 Klotz, Irene (6 September 2013). "Musk Says SpaceX Being "Extremely Paranoid" as It Readies for Falcon 9's California Debut". Space News. Retrieved 13 September 2013.

- 1 2 "Falcon 9's commercial promise to be tested in 2013". Spaceflight Now. Retrieved 17 November 2012.

- ↑ (p. 19)

- 1 2 3 "Octaweb". SpaceX. 29 July 2013. Retrieved 30 July 2013.

The Octaweb structure of the nine Merlin engines improves upon the former 3x3 engine arrangement. The Octaweb is a metal structure that supports eight engines surrounding a center engine at the base of the launch vehicle. This structure simplifies the design and assembly of the engine section, streamlining our manufacturing process.

- 1 2 "Landing Legs". SpaceX. 29 July 2013. Retrieved 30 July 2013.

The Falcon 9 first stage carries landing legs which will deploy after stage separation and allow for the rocket’s soft return to Earth. The four legs are made of state-of-the-art carbon fiber with aluminum honeycomb. Placed symmetrically around the base of the rocket, they stow along the side of the vehicle during liftoff and later extend outward and down for landing.

- 1 2 3 4 Lindsey, Clark (28 March 2013). "SpaceX moving quickly towards fly-back first stage". NewSpace Watch. Archived from the original on 16 April 2013. Retrieved 29 March 2013. (subscription required (help)).

- 1 2 3 Messier, Doug (28 March 2013). "Dragon Post-Mission Press Conference Notes". Parabolic Arc. Retrieved 30 March 2013.

Q. What is strategy on booster recover? Musk: Initial recovery test will be a water landing. First stage continue in ballistic arc and execute a velocity reduction burn before it enters atmosphere to lessen impact. Right before splashdown, will light up the engine again. Emphasizes that we don’t expect success in the first several attempts. Hopefully next year with more experience and data, we should be able to return the first stage to the launch site and do a propulsion landing on land using legs. Q. Is there a flight identified for return to launch site of the booster? Musk: No. Will probably be the middle of next year.

- 1 2 Svitak, Amy (24 November 2013). "Musk: Falcon 9 Will Capture Market Share". Aviation Week. Archived from the original on 23 October 2014. Retrieved 2 December 2013.

SpaceX is currently producing one vehicle per month, but that number is expected to increase to '18 per year in the next couple of quarters.' By the end of 2014, she says SpaceX will produce 24 launch vehicles per year.

- 1 2 3 4 5 6 Bergin, Chris (29 September 2015). "SpaceX successfully launches debut Falcon 9 v1.1". Retrieved 22 October 2015.

- ↑ "The Annual Compendium of Commercial Space Transportation: 2012" (PDF). Federal Aviation Administration. February 2013. Retrieved 17 February 2013.

- ↑ Clark, Stephen (18 May 2012). "Q&A with SpaceX founder and chief designer Elon Musk". SpaceFlightNow. Retrieved 5 March 2013.

- ↑ "SpaceX Test-fires Upgraded Falcon 9 Core for Three Minutes". Space News. Retrieved 11 August 2013.

- ↑ Bergin, Chris (20 June 2013). "Reducing risk via ground testing is a recipe for SpaceX success". NASASpaceFlight (not affiliated with NASA). Retrieved 21 June 2013.

- ↑ "Falcon 9". SpaceX. Retrieved 2 August 2013.

- ↑ "F9R 1000m Fin Flight | Onboard Cam and Wide Shot". Youtube. Google. 19 June 2014. Retrieved 18 February 2015.

- ↑ Johnson, Scott (25 November 2014). "SpaceX CRS-5: Grid Fins and a Barge". SpaceFlight Insider. SpaceFlight Insider. Retrieved 18 February 2015.

- ↑ Thompson, Amy (1 February 2015). "SpaceX Successfully Conducts Static Fire Test in Preparation for DSCOVR Launch". SpaceFlight Insider. SpaceFlight Insider. Retrieved 18 February 2015.

- ↑ "SpaceX's reusable rocket testbed takes first hop". 24 September 2012. Retrieved 7 November 2012.

- ↑ Mission Status Center, June 2, 2010, 1905 GMT, SpaceflightNow, accessed 2010-06-02, Quotation: "The flanges will link the rocket with ground storage tanks containing liquid oxygen, kerosene fuel, helium, gaserous nitrogen and the first stage ignitor source called triethylaluminum-triethylborane, better known as TEA-TAB."

- 1 2 3 "Falcon 9 Overview". SpaceX. 8 May 2010.

- ↑ Behind the Scenes With the World's Most Ambitious Rocket Makers, Popular Mechanics, 2009-09-01, accessed 11 December 2012. "It is the first since the Saturn series from the Apollo program to incorporate engine-out capability—that is, one or more engines can fail and the rocket will still make it to orbit."

- ↑ "Servo Motors Survive Space X Launch Conditions". MICROMO/Faulhabler. 2015. Retrieved 14 August 2015.

4-in pipes run from tanks of RP-1 and liquid oxygen (LOX). ... The fuel-trim valve adjusts the mixture in real time. The fuel-trim device consists of a servo-motor-controlled butterfly valve. To achieve the proper speed and torque, the design incorporates a planetary gearbox for a roughly 151:1 reduction ratio, gearing internal to the unit. The shaft of the motor interfaces with the valve directly to make fine adjustments. 'The basic mixture ratio is given by the sizing of the tubes, and a small amount of the flow of each one gets trimmed out,' explains Frefel. 'We only adjust a fraction of the whole fuel flow.'

- ↑ Clark, Stephen (22 February 2015). "100th Merlin 1D engine flies on Falcon 9 rocket". Spaceflight Now. Retrieved 24 October 2015.

- ↑ Young, Anthony (1 June 2015). The Twenty-First Century Commercial Space Imperative. SpringerBriefs in Space Development. p. 92. ISBN 9783319189291. Retrieved 24 October 2015.

- ↑ "SpaceX achieves Milestone in successful GEO Transfer Launch". Spaceflight 101. 3 December 2013. Retrieved 24 October 2015.

- ↑ Xu, Suzzane (5 March 2015). "How to Save a Rocket: SpaceX's plan for rocket recovery hits a few bumps". Yale Scientific. Yale. Retrieved 24 October 2015.

- ↑ Stanfield, Jennifer (21 May 2015). "Friction stir welding unites reliability, affordability". Phys.org. Retrieved 24 October 2015.

- ↑ Bergin, Chris (14 June 2013). "Testing times for SpaceX's new Falcon 9 v.1.1". NASASpaceflight. Retrieved 24 October 2015.

- 1 2 Mangels, John (25 May 2013). "NASA's Plum Brook Station tests rocket fairing for SpaceX". Cleveland Plain Dealer. Retrieved 27 May 2013.

- ↑ Leone, Dan (3 June 2015). "SpaceX to Retrieve Fairing that Washed Up in Bahamas". SpaceNews. Retrieved 24 October 2015.

- 1 2 Svitak, Amy (18 November 2012). "Dragon's "Radiation-Tolerant" Design". Aviation Week. Archived from the original on 3 December 2013. Retrieved 22 November 2012.

- ↑ Bergin, Chris (9 September 2015). "Full Thrust Falcon 9 stage undergoing testing at McGregor". NASASpaceFlight. Retrieved 18 September 2015.

- 1 2 3 Svitak, Amy (17 March 2015). "SpaceX's New Spin on Falcon 9". Aviation Week. Aviation Week Network. Retrieved 24 October 2015.

- 1 2 3 4 5 6 7 8 9 10 11 de Selding, Peter B. (15 September 2015). "Falcon 9 Upgrades: F9 v1.1 (current vehicle) to F9 Upgrade". SpaceNews journalist twitter feed. SpaceX slide, republished on Twitter. Retrieved 20 January 2016.

- ↑ de Selding, Peter B. (20 March 2015). "SpaceX Aims To Debut New Version of Falcon 9 this Summer". Space News. Retrieved 23 March 2015.

- ↑ Elon Musk on Twitter [elonmusk] (17 December 2015). "-340 F in this case. Deep cryo increases density and amplifies rocket performance. First time anyone has gone this low for O2. [RP-1 chilled] from 70F to 20 F" (Tweet). Retrieved 19 December 2015 – via Twitter.

- 1 2 3 4 Foust, Jeff (15 September 2015). "SES Betting on SpaceX, Falcon 9 Upgrade as Debut Approaches". Space News. Retrieved 19 September 2015.

- ↑ "Falcon 9 Launch Vehicle Payload User's Guide" (PDF). SpaceX. 21 October 2015. Retrieved 29 November 2015.

- 1 2 "Thomas Mueller's answer to Is SpaceX's Merlin 1D's thrust-to-weight ratio of 150+ believable?". Quora. 8 June 2015. Retrieved 20 January 2016.

- 1 2 Svitak, Amy (5 March 2013). "Falcon 9 Performance: Mid-size GEO?". Aviation Week. Retrieved 9 March 2013.

"Falcon 9 will do satellites up to roughly 3.5 tonnes, with full reusability of the boost stage, and Falcon Heavy will do satellites up to 7 tonnes with full reusability of the all three boost stages," [Musk] said, referring to the three Falcon 9 booster cores that will comprise the Falcon Heavy's first stage. He also said Falcon Heavy could double its payload performance to GTO "if, for example, we went expendable on the center core."

- ↑ "Falcon 9 Launch Vehicle Payload User's Guide" (PDF). 21 October 2015. Retrieved 29 November 2015.

- ↑ "Elon Musk on Twitter". Twitter. Retrieved 5 January 2016.

- 1 2 Svitak, Amy (21 March 2015). "SpaceX's Gwynne Shotwell Talks Raptor, Falcon 9, CRS-2, Satellite Internet and More". Aviation Week and Space Technology. Penton. Retrieved 8 May 2015.

So, we got the higher thrust engines, finished development on that, we're in [qualification testing]. What we're also doing is modifying the structure a little bit. I want to be building only two versions, or two cores in my factory, any more than that would not be great from a customer perspective. It's about a 30% increase in performance, maybe a little more. What it does is it allows us to land the first stage for GTO missions on the drone ship.

- ↑ de Selding, Peter B. (16 March 2015). "SpaceX Says Falcon 9 Upgrade Won't Require New Certification". Space News. Retrieved 8 May 2015.

- ↑ Clark, Stephen (20 February 2015). "SES signs up for launch with more powerful Falcon 9 engines". Spaceflight Now. Retrieved 8 May 2015.

- ↑ Bergin, Chris (16 October 2015). "SpaceX selects ORBCOMM-2 mission for Falcon 9's Return To Flight". NASASpaceFlight. Retrieved 23 October 2015.

- ↑ "Upgraded Falcon 9 First-Stage Static Fire | 9/21/15". Youtube. Google. 24 September 2015. Retrieved 25 September 2015.

First static fire of the upgraded Falcon 9's first stage with densified propellant.

- ↑ Clark, Stephen (25 September 2015). "First static fire completed on upgraded Falcon 9". Spaceflight Now. Retrieved 25 September 2015.

- ↑ Graham, William (21 December 2015). "SpaceX returns to flight with OG2, nails historic core return". NASASpaceFlight. Retrieved 22 December 2015.

- 1 2 First test of the Falcon 9-R (reusable) ignition system, 28 April 2013

- ↑ Abbott, Joseph (3 June 2013). "SpaceX finally tests new rocket". WacoTrib. Retrieved 4 June 2013.

- ↑ Abbot, Joseph (26 April 2013). "Heads up: SpaceX testing is about to get louder". Waco Tribune. Retrieved 28 April 2013.

- ↑ "Production at SpaceX". SpaceX. 24 September 2013. Retrieved 29 September 2013.

- ↑ Gwynne Shotwell (21 March 2014). Broadcast 2212: Special Edition, interview with Gwynne Shotwell (audio file). The Space Show. Event occurs at 36:35–37:00 and 56:05–56:10. 2212. Archived from the original (mp3) on 22 March 2014. Retrieved 22 March 2014.

hopefully you'll see us launching a couple of times a month starting in 2015.

- ↑ "Space Launch report, SpaceX Falcon Data Sheet". Retrieved 29 July 2011.

- ↑ Abbott, Joseph (8 May 2013). "SpaceX's Grasshopper leaping to NM spaceport". Waco Tribune. Retrieved 9 May 2013.

- ↑ Bergin, Chris (3 April 2015). "SpaceX preparing for a busy season of missions and test milestones". NASASpaceflight. Retrieved 24 October 2015.

- ↑ Bergin, Chris (11 January 2012). "Home Forums L2 Sign Up ISS Commercial Shuttle SLS/Orion Russian European Chinese Unmanned Other SpaceX to begin testing on Reusable Falcon 9 technology this year". NASASpaceFlight. Retrieved 22 October 2015.

- 1 2 Simberg, Rand (8 February 2012). "Elon Musk on SpaceX's Reusable Rocket Plans". Popular Mechanics. Retrieved 8 March 2013.

- ↑ Boyle, Alan (24 December 2012). "SpaceX launches its Grasshopper rocket on 12-story-high hop in Texas". MSNBC Cosmic Log. Retrieved 25 December 2012.

- ↑ Norris, Guy (28 April 2014). "SpaceX Plans For Multiple Reusable Booster Tests". Aviation Week. Retrieved 28 April 2014.

- ↑ Clark, Stephen (10 January 2015). "Dragon successfully launched, rocket recovery demo crash lands". Retrieved 5 May 2015.

- ↑ "CRS-6 First Stage Landing". video. Retrieved 16 April 2015.

- ↑ "Elon Musk on Twitter". Twitter. Archived from the original on 15 April 2015. Retrieved 14 April 2015.

- ↑ Amos, Jonathan (3 December 2013). "SpaceX launches SES commercial TV satellite for Asia". BBC News. Retrieved 4 January 2015.

The commercial market for launching telecoms spacecraft is tightly contested, but has become dominated by just a few companies - notably, Europe's Arianespace, which flies the Ariane 5, and International Launch Services (ILS), which markets Russia's Proton vehicle. SpaceX is promising to substantially undercut the existing players on price, and SES, the world's second-largest telecoms satellite operator, believes the incumbents had better take note of the California company's capability. 'The entry of SpaceX into the commercial market is a game-changer'

- ↑ http://web.archive.org/web/20131008212322/http://www.spacex.com/usa.php. Archived from the original on 8 October 2013. Retrieved 7 October 2013. Missing or empty

|title=(help) - ↑ William Harwood (5 March 2014). "SpaceX, ULA spar over military contracting". Spaceflight Now. Retrieved 7 March 2014.

- ↑ Foust, Jeff (22 August 2011). "New opportunities for smallsat launches". The Space Review. Retrieved 27 September 2011.

SpaceX ... developed prices for flying those secondary payloads ... A P-POD would cost between $200,000 and $325,000 for missions to LEO, or $350,000 to $575,000 for missions to geosynchronous transfer orbit (GTO). An ESPA-class satellite weighing up to 180 kilograms would cost $4–5 million for LEO missions and $7–9 million for GTO missions, he said.

- ↑ "Spaceflight Now - Worldwide launch schedule". Spaceflight Now Inc. 1 June 2013. Retrieved 24 June 2013.

- ↑ Foust, Jeff (27 March 2013). "After Dragon, SpaceX's focus returns to Falcon". NewSpace Journal. Retrieved 5 April 2013.

- ↑ Ferster, Warren (29 September 2015). "Upgraded Falcon 9 Rocket Successfully Debuts from Vandenberg". SpaceNews. Retrieved 22 October 2015.

- ↑ Musk, Elon. "Tweet from Elon Musk about the failure". Twitter. Retrieved 1 July 2015.

External links

| Wikimedia Commons has media related to Falcon 9. |

| Wikinews has related news: SpaceX successfully test fires Falcon 9 rocket in Texas |

- Falcon 9 official page

- Falcon Heavy official page

- Test firing of two Merlin 1C engines connected to Falcon 9 first stage, Movie 1, Movie 2 (18 January 2008)

- Press release announcing design (9 September 2005)

- SpaceX hopes to supply ISS with new Falcon 9 heavy launcher (Flight International, 13 September 2005)

- SpaceX launches Falcon 9, With A Customer (Defense Industry Daily, 15 September 2005)