Extractive metallurgy

Extractive metallurgy is a branch of metallurgical engineering wherein process and methods of extraction of metals from their natural mineral deposits are studied. The field is a materials science, covering all aspects of the types of ore, washing, concentration, separation, chemical processes and extraction of pure metal and their alloying to suit various applications, sometimes for direct use as a finished product, but more often in a form that requires further working to achieve the given properties to suit the applications.[1]

The field of ferrous and non-ferrous extractive metallurgy have specialties that are generically grouped into the categories of mineral processing, hydrometallurgy, pyrometallurgy, and electrometallurgy based on the process adopted to extract the metal. Several processes are used for extraction of same metal depending on occurrence and chemical requirements.

Mineral processing

Mineral processing begins with beneficiation, consisting of initially breaking down the ore to required sizes depending on the concentration process to be followed, by crushing, grinding, sieving etc. Thereafter, the ore is physically separated from any unwanted impurity, depending on the form of occurrence and/or further process involved. Separation processes take advantage of physical properties of the materials. These physical properties can include density, particle size and shape, electrical and magnetic properties, and surface properties. Major physical and chemical methods include magnetic separation, froth floatation, leaching etc., whereby the impurities and unwanted materials are removed from the ore and the base ore of the metal is concentrated, meaning the percentage of metal in the ore is increased. This concentrate is then either processed to remove moisture or else used as is for extraction of the metal or made into shapes and forms that can undergo further processing, with ease of handling.

Ore bodies often contain more than one valuable metal. Tailings of a previous process may be used as a feed in another process to extract a secondary product from the original ore. Additionally, a concentrate may contain more than one valuable metal. That concentrate would then be processed to separate the valuable metals into individual constituents.

Hydrometallurgy

Hydrometallurgy is concerned with processes involving aqueous solutions to extract metals from ores. The first step in the hydrometallurgical process is leaching, which involves dissolution of the valuable metals into the aqueous solution and /or a suitable solvent. After the solution is separated from the ore solids, the extract is often subjected to various processes of purification and concentration before the valuable metal is recovered either in its metallic state or as a chemical compound. This may include precipitation, distillation, adsorption, and solvent extraction. The final recovery step may involve precipitation, cementation, or an electrometallurgical process. Sometimes, hydrometallurgical processes may be carried out directly on the ore material without any pretreatment steps. More often, the ore must be pretreated by various mineral processing steps, and sometimes by pyrometallurgical processes.[2]

Pyrometallurgy

Pyrometallurgy involves high temperature processes where chemical reactions take place among gases, solids, and molten materials. Solids containing valuable metals are treated to form intermediate compounds for further processing or converted into their elemental or metallic state. Pyrometallurgical processes that involve gases and solids are typified by calcining and roasting operations. Processes that produce molten products are collectively referred to as smelting operations. The energy required to sustain the high temperature pyrometallurgical processes may derive from the exothermic nature of the chemical reactions taking place. Typically, these reactions are oxidation, e.g. of sulfide to sulfur dioxide . Often, however, energy must be added to the process by combustion of fuel or, in the case of some smelting processes, by the direct application of electrical energy.

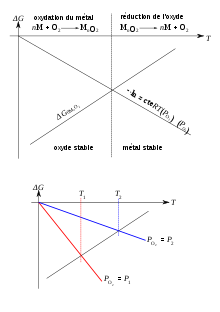

Ellingham Diagrams are a useful way of analysing the possible reactions, and so predicting their outcome.

Electrometallurgy

Electrometallurgy involves metallurgical processes that take place in some form of electrolytic cell. The most common types of electrometallurgical processes are electrowinning and electro-refining. Electrowinning is an electrolysis process used to recover metals in aqueous solution, usually as the result of an ore having undergone one or more hydrometallurgical processes. The metal of interest is plated onto the cathode, while the anode is an inert electrical conductor. Electro-refining is used to dissolve an impure metallic anode (typically from a smelting process) and produce a high purity cathode. Fused salt electrolysis is another electrometallurgical process whereby the valuable metal has been dissolved into a molten salt which acts as the electrolyte, and the valuable metal collects on the cathode of the cell. The fused salt electrolysis process is conducted at temperatures sufficient to keep both the electrolyte and the metal being produced in the molten state. The scope of electrometallurgy has significant overlap with the areas of hydrometallurgy and (in the case of fused salt electrolysis) pyrometallurgy. Additionally, electrochemical phenomena play a considerable role in many mineral processing and hydrometallurgical processes.

References

- ↑ Brent Hiskey "Metallurgy, Survey" in Kirk-Othmer Encyclopedia of Chemical Technology, 2000, Wiley-VCH, Weinheim. doi:10.1002/0471238961.1921182208091911.a01

- ↑ Boundless. “Extractive Metallurgy.” Boundless Chemistry. Boundless, 21 Jul. 2015. Retrieved 18 Mar. 2016 from https://www.boundless.com/chemistry/textbooks/boundless-chemistry-textbook/metals-20/metallurgic-processes-142/extractive-metallurgy-559-3578/

Further reading

- Gilchrist, J.D. (1989). "Extraction Metallurgy", Pergamon Press.

- Mailoo Selvaratnam, (1996): "Guided Approach to Learning Chemistry