Energy Multiplier Module

The Energy Multiplier Module (EM2 or EM squared) is a nuclear fission power reactor under development by General Atomics.[1] It is a modified version of the Gas Turbine Modular Helium Reactor (GT-MHR) and is capable of converting spent nuclear fuel into electricity and industrial process heat, without separative or conventional nuclear reprocessing.[2]

Design specifications

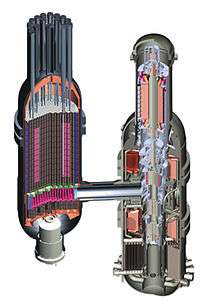

The EM2 is an advanced modular reactor expected to produce 265 MWe (500 MWth) of power at 850 °C (1,600 °F) and be fully enclosed in an underground containment structure for 30 years without requiring refueling. The EM2 differs from current reactors as it does not use water coolant but is instead a gas-cooled fast reactor, which uses helium as a coolant for an additional level of safety. The reactor uses a composite of silicon carbide as cladding material, and beryllium oxide as neutron reflector material. The reactor unit is coupled to a direct-drive helium gas turbine which in turn drives a generator for the production of electricity.

The nuclear core design is based upon a new conversion technique in which an initial “starter” section of the core provides the neutrons required to convert used nuclear fuel, thorium or depleted uranium (DU) into burnable fissile fuel.[3] First generation EM2 units use uranium starters (approximately 15 percent U235) to initiate the conversion process.[4] The starter U235 is consumed as the used nuclear fuel/DU or used nuclear fuel/thorium is converted to fissile fuel. The core life expectancy is approximately 30 years (using used nuclear fuel and DU) without refueling.

Substantial amounts of valuable fissile material remain in the EM2 core at the end of life. This material is reused as the starter for a second generation of EM2s, without conventional reprocessing. There is no separation of individual heavy metals required and no enriched uranium needed. Only unusable fission products would be removed and stored.

All EM2 heavy metal discharges could be recycled into new EM2 units, effectively closing the nuclear fuel cycle, which minimizes nuclear proliferation risks and the need for long-term repositories to secure nuclear materials.

Economics and workforce capacity

The expected cost advantages of EM2 lie in its simplified power conversion system, which operates at high temperatures yielding approximately 50 percent greater efficiency and a corresponding one-third reduction in materials requirements than that of current nuclear reactors.[5]

Each module can be manufactured in either U.S. domestic or foreign facilities using replacement parts manufacturing and supply chain management with large components shipped by commercial truck or rail to a site for final assembly, where it will be fully enclosed in an underground containment structure.

Nuclear waste

The EM2 utilizes used nuclear fuel, also referred to as “spent fuel” from current reactors, which are light water reactors. It can tap an estimated 97% of unused fuel that current reactors leave behind as waste.

Spent fuel rods from conventional nuclear reactors are put into storage and considered to be nuclear waste, by the nuclear industry and the general public.[6] Nuclear waste retains more than 99% of its original energy; the current U.S. inventory is equivalent to nine trillion barrels of oil - four times more than the known reserves. EM2 uses this nuclear waste to produce energy.

Non-proliferation

By using spent nuclear waste and depleted uranium stockpiles as its fuel source, a large-scale deployment of the EM2 is expected to reduce the long-term need for uranium enrichment and eliminate conventional nuclear reprocessing.[7]

Conventional light water reactors require refueling every 18 months. EM2’s 30-year fuel cycle minimizes the need for fueling handling and can reduce the proliferation concerns associated with refueling.

Energy safety and security

EM2 utilizes passively safety systems designed to safely shutdown using only gravity and natural convection in emergency conditions.[8] Control rods and drums are automatically inserted during a loss of power incident via gravity. Natural convection flow is used to cool the core during whole site loss of power incidents. No external water supply is necessary for emergency cooling. The use of silicon carbide as a safety-enhanced fuel cladding in the core ensures no hydrogen production during accident scenarios and allows an extended period of response when compared to the use of Zircaloy metal cladding in current reactors, which are reactive and not as heat resistant as ceramics in EM2.

Underground siting in a silo improves safety and security of the plant to terrorism and other threats.

The EM2’s high operating temperature can provide process heat for petrochemical fuel products and alternative fuels, such as biofuels and hydrogen.[9]

See also

- American Association for the Advancement of Science

- Nuclear Energy Institute

- Nuclear power

- Nuclear safety in the United States

- Economics of new nuclear power plants

- United States Department of Energy

References

- ↑ Logan Jenkins (10 January 2013). "JENKINS: Hot young prospect to replace old San Onofre reactors". San Diego Union Tribune. Retrieved 19 January 2013.

- ↑ Freeman, Mike (Feb 24, 2010). "Company has plan for small reactors". San Diego Union Tribune.

- ↑ “With Disposal Uncertain, Waste Burning Reactors Gain Traction – EM2 to Burn LWR Fuel,” Nuclear New Build Monitor, March 15, 2010

- ↑ Parmentola, J. "Blue Ribbon Commission Webcast on America's Nuclear Future". Retrieved 15 March 2010.

- ↑ Smith, Rebecca (Feb 22, 2010). "General Atomics Proposes a Plant That Runs on Nuclear Waste". Wall Street Journal.

- ↑ Parmentola, John (March 11, 2010). "Letter to the Editor in Response to "Nuclear power – not a green option – it generates radioactive waste; it requires uranium that's dangerous to mine; it's hugely expensive,"". Los Angeles Times.

- ↑ Fairley, Peter (May 11, 2010). "7. "Downsizing Nuclear Power Plants – Modular designs rely on 'economies of multiples' to make small reactors pay off big,"". IEEE Spectrum. horizontal tab character in

|title=at position 3 (help) - ↑ http://www.andrew.cmu.edu/user/ayabdull/Prasad_SMRDesc.pdf

- ↑ "Small Nuclear Power Reactors". World Nuclear Association. August 2010.

10. Wald, Matthew L.(Sept. 24, 2013). Atomic Goal: 800 Years of Power From Waste". New York Times. Retrieved 10 December 2013.

11. Lee, Morgan. (Aug. 18, 2013). Smaller, transportable nuclear reactor. UT San Diego. Retrieved 5 November 2013.

12. King, Llewellyn. (Aug. 21, 2013). For nuclear, good things come in small packages. Christian Science Monitor. Retrieved 10 December 2013.

13. The Engineer (Sept. 11, 2013). General Atomics presents small modular reactor.The Engineer. Retrieved 10 December 2013.

14. Haggerty, Dan (Sept. 12, 2013). Holding the key to changing the future energy supply. ABC-KGTV 10. Retrieved Sept. 13, 2013.

15. Hood, David (Sept. 5, 2013). Rohrabacher pitches scaled-down nuclear power. Orange County Register. Retrieved 15 September 2013.

16. Bullis, Kevin (Aug. 19, 2013). A Nuclear Reactor Competitive with Natural Gas. MIT Technology Review. Retrieved 10 December 2013.

17. St. John, Alison (May 21, 2012). A better nuclear power plant? KPBS News. Retrieved 12 September 2012.

External links

- Official website

- 2011-11-28: Presentation about the EM2 reactor at the Department of Nuclear Engineering, University of California-Berkeley, ustream video Previous presentation

- 2015-05: Testimony of the Sr. Vice President of General Atomics before the Committee on Science, Space and Technology: