Crucible Industries

| |

| Limited liability company | |

| Industry | Steel |

| Headquarters | Solvay, New York, a suburb of Syracuse[1] |

Area served | Global |

Key people |

James D. Beckman,[2] president |

| Products |

Specialty steels:[3] CPM High Speed Steel CPM Stainless Tool Steel CPM Tool Steel High-speed steel Stainless steel Tool steel |

Number of employees | 550 (2009)[4] |

| Website | CrucibleIndustries.com |

Crucible Industries, commonly known as Crucible, is an American company which develops and manufactures specialty steels and is the sole producer of Crucible Particle Metallurgy (CPM) steels. The company produces high speed, stainless and tool steels for the automotive, cutlery, aerospace and machine tool industries.[5][6]

Crucible's history spans over 100 years, and the company inherited some of its ability to produce high-grade steel from England beginning in the late 1800s. Thirteen crucible-steel companies merged in 1900 to become the largest producer of crucible steel in the United States, and this company evolved into a corporation with 1,400 employees in several states. Crucible declined in tandem with the automotive industry during the 1980s, recovering over the next decade. Although the company entered bankruptcy in 2009, a Cleveland corporation revived it as Crucible Specialty Metals Division to continue producing specialty steels at its original site.[7][8]

The CPM process produces uniform steel at the molecular level by spraying the liquid metal into quickly cooling droplets, forming a powder which is then heat-pressed into ingots. This and other steels are used in many industries and by production and custom knife manufacturers.[9]

History

1. Iron ore + limestone sinter

2. Coke

3. Elevator

4. Feedstock inlet

5. Layer of coke

6. Layer of sinter pellets of ore and limestone

7. Hot blast (around 1200 °C)

8. Removal of slag

9. Tapping of molten pig iron

10. Slag pot

11. Torpedo car for pig iron

12. Dust cyclone for separation of solid particles

13. Cowper stoves for hot blast

14. Smoke outlet (can be redirected to carbon capture & storage (CCS) tank)

15: Feed air for Cowper stoves (air pre-heaters)

16. Powdered coal

17. Coke oven

18. Coke

19. Blast furnace gas downcomer

The Crucible Steel Company of America was formed from the merger of thirteen crucible-steel companies in 1900. This, known as "the great consolidation of 1900", inspired other steel companies to form U.S. Steel a year later.[10] From 1900 through the 20th century, Crucible developed and patented new steels and brought new steel-production methods to the United States.[10] C. H. Halcomb, Jr. was Crucible's first president and general manager. Two years later he left Crucible, building the Halcomb Steel mill next door (where he installed the first electric-arc melting furnace in the U.S.).[7][8]

In 1911 Crucible acquired Halcomb Steel, merging the Halcomb plant with the new Sanderson plant to form the Sanderson-Halcomb Works. In 1955 it began producing vacuum-arc-remelted steels, becoming the first company to use this process commercially. By 1939 Crucible was the largest producer of tool steel in the United States, making over 400 products (more than any other steel company). It had nine mills in four states, two coal mines, a water company and a half-interest in a Mesabi ore mine.[11]

From 1968 to 1984 Crucible was owned by Colt Industries; in 1985, its salaried employees bought it back. By then, the company was known as Crucible Materials Corporation. Fourteen hundred employees worldwide worked for a number of companies, including Crucible Specialty Metals in Solvay, New York; Trent Tube in East Troy, Wisconsin; Crucible Magnetics in Elizabethtown, Kentucky; Crucible Compaction Metals Operations in Oakdale, Pennsylvania; the Cancer Research Center in Pittsburgh, and Crucible Limited in Sheffield, England. In 1989, the number of employees was reduced to 600 after a strike.[7]

The 1980s saw layoffs and plant closures across the U.S.; more than 200,000 workers lost their jobs, and more than 400 mills and divisions of plants (including Crucible's Midland plant) closed.[12] In 1984 Crucible made the titanium alloy used in the artificial heart implanted by Robert Jarvik, and donated corrosive-resistant steel used to help renovate the Statue of Liberty.[7]

During the 1990s Crucible expanded its operations to Canada, working with General Motors and building a 35,000-square-foot (3,300 m2) facility with newly patented smelting and processing equipment costing $25 million. Although the number of employees increased to about 1,400, from 2001 to 2003 200 were laid off.[7]

In 2004 Crucible entered the knife market,[7] and in May 2009 the company filed for Chapter 11 bankruptcy. That October JP Industries (a private equity group) purchased the operating assets of the Crucible Specialty Metals Division, formed Crucible Industries and restarted the Geddes steel mill.[7]

Company names

A number of steel companies have operated in Syracuse, maintaining Crucible's intellectual property and patents.[7] In 1870, William A. Sweet founded the Sweet Iron Works. Sanderson Brothers of Sheffield, England, bought the Sweet Iron Works for U.S. production in 1876, renaming the steelworks Sanderson. In 1900, Sanderson's Syracuse steelworks merged into the Crucible Steel Company of America.[13] In 1946 the Sanderson and Halcomb steelworks were renamed the Sanderson-Halcomb Works, later becoming the Syracuse Works of Crucible Steel. In 1968, Crucible became Colt's Crucible Specialty Metals Division. Colt consolidated its basic-materials group into the Crucible Materials Corporation in 1983.

Founding companies

According to ExplorePAHistory.com, "By 1877, the region's fourteen medium-scale crucible steel factories produced nearly three-fourths of the nation's output. Metal-shaping factories across the country depended on cutting tools made of crucible steel through the 1920s, when electric steel furnaces gained prominence."[14] Three companies which merged to form Crucible into the largest U.S. crucible-steel-producing company were:[10][15]

- Sanderson Brothers began producing steel in Sheffield, England in 1776. In 1873, it was using a gas-fired crucible melting furnace.[16] Sanderson sold its Syracuse operation to Crucible, expanding its English company with the purchase of Samuel Newbould and Company.[13]

- Hussey, Wells and Company of Pittsburgh, founded in 1859, was the first company in America to manufacture crucible steel. Its partners were Curtis G. Hussey (who formed the Pittsburgh and Boston Mining Corporation to mine copper) and Thomas Marshall Howe (banker, investor, Congressman, assistant adjutant general of Pennsylvania and the first president of the Pittsburgh Chamber of Commerce. Thomas' son, George, helped form Crucible. Hussey and James M. Cooper formed C. G. Hussey and Company to roll and market copper. Before merging with Crucible, Hussey, Wells and Company became Howe, Brown and Company when George joined his father.

- Park, Brother and Company of Pittsburgh, founded in 1860, was the second company to produce crucible steel in the U.S. James Park, Jr. and the elder David E. Park began the company after working with their father for twenty years. In 1857, James Jr. founded the Lake Superior Copper Works to sheath ship hulls. After encountering Hussey, Howe and Wells, he followed them into manufacturing crucible steel. Park built the Black Diamond (Park) Steel Works, and had interests in a suspension-bridge company and several banks. David's sons, David E. Jr., William G. and James H. Park, led in forming Crucible. In 1900, Park Steel was the largest producer of crucible and special-purpose open-hearth steels in the world.[10]

The other companies which formed Crucible were:

- Aliquippa Steel Company, several miles north of Pittsburgh on the Ohio River

- Anderson, DuPuy and Company

- Beaver Falls Steel Works

- Burgess Steel and Iron Works

- Crescent Steel of Pittsburgh (founded 1865)

- Cumberland Steel and Tin Plate Company

- Isaac Jones' Pittsburgh Steel Works (later Anderson, Deputy and Company; founded 1845)

- LaBelle Steel Company (formerly Reiter, Hartman and Company) of Allegheny, Pennsylvania (founded 1863)

- Singer, Nimick and Company of Pittsburgh (founded 1848)

- Spaulding and Jennings Company

Timeline

The following timeline provides references and events in the context of Crucible's history. Its primary source is the Syracuse Post-Standard archives, with other sources noted.[7]

Sanderson Brothers and Company

1776: The Naylor and Sanderson Steel Mill was established in Sheffield, England, and began producing tool steel with the crucible method.[13] By 1873 it was trading as Sanderson Brothers and Company, and using a gas-fired-crucible melting furnace.[16]

In 1876 Sanderson Brothers and Company bought Sweet Iron Works, which had been established in 1870 in Syracuse.[17] Sheffield was known for its hard, durable steel, and Syracuse was known for its hard steel. Contemporary U.S. tariffs gave Sanderson an incentive for a U.S. operation.[8] In 1878, Sanderson had $450,000 in capital and the following officers: Robert B. Campbell of New York, president; Samuel William Johnson of New York, secretary and William A. Sweet of Syracuse, general manager.[17]

In 1900, thirteen crucible-steel manufacturing companies formed the Crucible Steel Company of America. Sanderson divested itself of its American operation, offering 500,000 shares of stock for $50 million.[15][18] Crucible's fifth annual report (published in 1905) showed debts of $3.6 million, $2.4 million less than the year before.[19]

Halcomb Steel

In 1902 C. H. Halcomb Jr., Sanderson's president and general manager, left the company and built the Halcomb Steel mill next to the Sanderson mill. Halcomb installed the first electric arc furnace (EAF) in the United States in 1906.[8][20][21] In 1911 the company was acquired by Crucible, which doubled the size of its western branch warehouse (now in Chicago) in 1913.

Hoyt-Noe Steel Company

By 1913, Thatcher Hoyt and Paul E. Noe formed the Hoyt-Noe Steel Company in Chicago. Hoyt had been representing crucible steels for twenty years; his previous companies included the Braeburn Steel Company, Singer, Nimick and Company and the Sanderson Brothers Steel Company.[22]

Crucible

Crucible patented the first formally classified high-speed steel, AISI T1 (German 18-0-1), in 1910, and its basic formula was used for the next forty years. After other high-speed steels were produced, T1 remained one of the most commonly used commercial high-speed steels for the next century.[23][24] The next year Crucible formed the Pittsburg Crucible Steel Company, purchasing a 423-acre (171 ha) site from Midland Steel on the Ohio River near Pittsburgh for $7.5 million to build a new plant.[25] Midland, Pennsylvania became Crucible's planned town.[12][26]

During the 1920s and 1930s World War I financier Horace S. Wilkinson oversaw Crucible president Frederick B. Hufnagel, refusing to modernize and controlling the company's finances as he pleased. This ended with the creation of the Security and Exchange Commission in 1934 and Wilkinson's death in 1937.[27] At the beginning of World War II Crucible was the largest producer of tool steels in the United States, manufacturing more types of steel than any other company. The company used thirty metals to make 400 commonly used alloy steels. It had nine mills in New York, New Jersey, Pennsylvania and Ohio, two coal mines, a water company and a half-interest in a Mesabi Range iron ore mine. Now the company's chairman, Hufnagel brought in Raoul Eugene Desvernine[28] as president. With a legal background, Desvernine focused on improving sales. The company had about 15,000 customers, net sales of $60 million and earnings of $4 million in 1937. The following year, Crucible lost $2 million as its sales halved during the recession of 1937–38.[11][18]

When Crucible sought to borrow money in 1940, the Mellon Security Corporation insisted on a full audit. This resulted in a $40 million revaluation of the company's property and plants (down to $81 million) and the loss of its fiscal surplus.[27] On December 7, 1941, when the U.S. entered World War II, Syracuse was considered the Porretta Terme (Italy's gear-producing center) of America.[8]

In 1945 William P. Snyder Jr., president of Snyder Mining Company of Pittsburgh and a Crucible stockholder, brought in president William H. Colvin Jr. With the board's approval, Colvin closed four of the company's eleven operations and began a $46 million modernization.[27] The Syracuse plants were consolidated in 1946 into the Sanderson-Halcomb Works. In 1949, Crucible began operations in an $18 million sheet and strip mill at the Midland works, becoming the first steel mill to use hot and cold rolling of stainless and high-alloy sheet and strip. Iron Age, manufacturer of the hot reversing mill, called this a transition from a curiosity to standard production practice; ovens on both sides of the rolls could better control the steel's temperature.[27][29]

When Crucible removed escape clauses from its employee contracts after the war, the company received approval from the United Steelworkers.[30] During the 1950s, shortages of tungsten and vanadium caused by the wartime drive for cheaper alloying metals resulted in the development of AISI M2 high-speed steel.[24] Colt Industries bought Crucible Steel Corporation of America in 1968, and the Syracuse works become Colt's Crucible Specialty Metals Division. In 1975, Crucible began marketing its products in the Soviet Union.[31]

During the 1980s the AISI reported that more than 200,000 steelworkers in the U.S. had lost their jobs, and more than 400 mills and plant divisions were closing (including Crucible's Midland plant near Pittsburgh). Jones & Laughlin Steel bought the Midland plant and merged with Republic Steel to form the LTV Steel Corporation, which went bankrupt.[12]

In 1981 Colt moved the Crucible and Trent Tube Divisions to Syracuse from Pittsburgh, and the following year it began closing its Crucible Steel Plant (laying off 400 workers).[32] In 1983 Colt Industries consolidated its basic-materials group into the Crucible Materials Corporation, with its headquarters in New York City. This was the last year that Crucible Specialty Metals negotiated union contracts without a strike.

In 1984 Crucible manufactured the titanium alloy used in the artificial heart implanted by Robert Jarvik, and donated corrosion-resistant steel for the renovation of the Statue of Liberty. The following year, Crucible Materials Corporation's salaried employees purchased the corporation’s stock in a leveraged buyout and moved its headquarters to Syracuse. The purchase price ($135 million) included the 1,400-employee Crucible Specialty Metals plant in Solvay; Trent Tube in East Troy, Wisconsin; Crucible Magnetics in Elizabethtown, Kentucky; Crucible Compaction Metals Operations in Oakdale, Pennsylvania; Crucible Research Center in Pittsburgh, and Crucible Limited in Sheffield, England.

In 1988, Crucible Specialty Metals modernized its plant and the division employed 1,425 people worldwide. The Crucible Service Centers Division opened its Camillus, New York headquarters in 1989, marketing specialty steel products worldwide. That year, the workers struck; when a contract was signed, only 600 of 1,100 workers were called back to work.

In 1991 Crucible Materials and General Motors' Central Foundry Division begin three years of joint research and development in die casting, tooling and machine elements, and Crucible Materials Corporation purchased Sanderson Specialty Steels of Canada. Two years later union workers rejected a company contract offer, continuing to work. At this time, Crucible employed about 700 union workers. By 1998 CMC employed 820 workers and invested $25 million in a new, 35,000 sq ft (3,300 m2) facility for manufacturing newly patented smelting and processing equipment.

In 2000, the U.S. Department of Labor sued Crucible Materials Corporation over its pension plan for salaried employees. From 2001 to 2003, the corporation laid off 186 salaried and hourly workers on a rotating basis. CMC employed 1,209 workers, 722 union workers and 487 salaried workers in Geddes and its distribution center in Camillus. In 2004 Crucible Specialty Metals entered the knife market, moving its Camillus operation to the Geddes plant.

The corporation filed for Chapter 11 bankruptcy in May 2009,[7][33] and in October JP Industries (a private equity group in Cleveland) purchased the operating assets of the Crucible Specialty Metals Division and formed Crucible Industries.[34] A month later, the Geddes steel mill was restarted.[35]

In 2010, Crucible partnered with Latrobe Specialty Steel Distribution to market its steels. According to Crucible president James Beckman, "Latrobe Distribution offers everything we wanted in a partner for our CPM grades of steel". Latrobe, with eight locations in North America, is a division of Latrobe Specialty Steel of Latrobe, Pennsylvania.[9][34][36] That year Crucible partnered with Robert Zapp Werkstofftechnik, a division of the Zapp Group, to sell Crucible Particle Metallurgy products worldwide except for North America and Japan.[6]

Knife design and manufacturing

Many production and custom knife manufacturers use Crucible steels.[37][38][39][40] Chris Reeve collaborated with Dick Barber of Crucible to develop the S30V and S35VN steel alloys, and Chris Reeve Knives uses these and other steels.[41][42][43] Bob Loveless introduced 154CM stainless-steel knives in 1972. A founder and president of the Knifemakers' Guild, Loveless has designed for Gerber Knives,[44] Lone Wolf Knives and Beretta.[45] Schrade Cutlery[46] and Spyderco use 154CM, 440C, D2, S30V, S60V and S90V steel,[47][48][49] and Ernest Emerson's knives are hard-ground from differentially heat-treated A2 tool steel.[50] Emerson Knives machines blades from 154CM steel,[51] and Mike Snody uses A2, S35V, 154CM and 440C steels.[52][53] Phill Hartsfield's katana-style blades are hand-ground from A2 tool steel and differentially edge-hardened.[54][54][55][56] Ken Onion's Kershaw's Blur uses CPM S30V steel.[57]

Products

Crucible Particle Metallurgy (CPM) steels are used in the automotive, aerospace and tool industries.[34] The list of blade materials describes several CPM products, and the company's website has data sheets for all of them.[58] The following table includes trademarks of Crucible users.

| Product type | Product |

|---|---|

| CPM® High Speed Steel | M4 HC (HS), REX 20® (HS), REX 45® (HS), REX 54® HS, REX 66® (HS), REX 76® (HS), REX 86® HS, REX 121®, T15 (HS) |

| CPM® Stainless Tool Steel | 154, S110V®, S125V®, S30V®,[58] S35VN®,[59] S90V® |

| CPM® Tool Steel | 1V®, 3V®, 4V®, 9V®, 10V®, 15V® |

| High Speed | M2,[24] M4, M50 |

| Stainless 300 Series | 303, 303 SE, 304L, 316L, 321, 347, Alloy 20, UNS 21800, XM-19 |

| Stainless 400 Series | 154CM,[60] 410, 416, 416R, 420, 422, 430, 430F, 431, 440A, 440C |

| Stainless Precipitation Hardness Grades | 17-4, 17-4 SUPER X, VAR 15-5 |

| Tool | A2,[61] CRUWEAR, D2, H13, WR95 (H10 Mod) |

Although the following metals add general characteristics to an alloy, its actual characteristics are determined by a number of factors. Metallurgy for the non-Metallurgist[62] is an introduction to the field.

| Metal | General characteristics |

|---|---|

| Chromium | Hardness, corrosion resistance, wear resistance |

| Cobalt | Electrical, hot hardness when used with molybdenum and tungsten |

| Nickel | Hardness, tensile strength, ductility |

| Molybdenum | Depth of hardness, toughness, strength at higher temperatures, machineability, weldability |

| Vanadium | Very fine grain, fatigue resistance, abrasion resistance at average and higher temperatures |

| Tungsten | Hardness at red heat |

CPM process

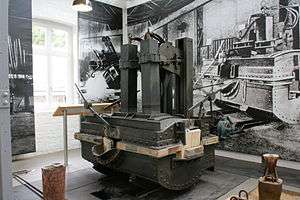

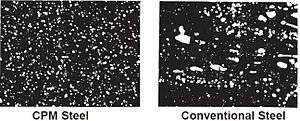

Conventional and CPM steel-making smelts ore into steel with an electric arc furnace, refines it by removing some carbon, reducing it by removing the sulphur.[63] Further refining may use argon oxygen decarburization, an implementation of powder metallurgy. The conventional process teems[63] (distributes and pours) the steel into ingot molds. The steel slowly solidifies, allowing the elements to segregate into non-uniform patterns at the microscopic level.

The CPM process pours molten steel through a small nozzle. High-pressure gas atomizes the liquid stream into a spray which rapidly cools the steel into a uniform powder. The powder then goes into high-pressure containers and is heated at forge temperatures to press the powder into ingots; this is known as hot isostatic pressing (HIP), and the resulting metal is uniform.[9] Both processes then use hot or cold rolling to toughen the steel and mill it into finished products.[9]

Publications

Cataloged Crucible

- Crucible Steel Company of America, Condensed suggestions for steel workers. BiblioBazaar (1902, reprint 2010) ISBN 9781175479105

- Crucible Steel Company of America, High Speed Steel. (1912, reprint 2011) Nabu Press, ISBN 9781272198145

- Crucible Steel Company of America, Crucible Steel Company of America (1925) ASIN B002683KAG

Crucible

- Crucible Steel Company of America, The Treatment of Steel. (1902)

- Crucible Steel Company of America, Sanderson Bros. Steel Works. (1911)

- Crucible Steel Company of America, Steels and Alloys for Special Purposes (1912)

- Underhill, Earl M.; Crucible Steel Company of America, Permanent magnet design: including a discussion of permanent magnet measurements (1943)

- Payson, Peter; Crucible Steel Company of America, The Annealing of Steel. (1944) Payson

- Crucible Steel Company of America, The Fabricator's Handbook - How to Fabricate Rezistal Stainless Steels Produced by Crucible Steel Company of America (1955)

- Mathews, John A. (1872–1935), Crucible Steel Company of America. Central Research Laboratory. Library (1959)

- Banerjee, B. R.; Hauser, J. J.; Crucible Steel Company of America, Effect of Processing Variables on Crack Propagation of High-strength Steels and Titanium: Fracture Micromechanics in High-strength Steels, Crucible Steel Company of America, Central Research Laboratory (1963)

- Crucible Steel Company of America. Library; Ussack, P., Continuous Casting of Steel. (3 ed. 1964) Volume 12, Library. Bibliographical series.

Crucible and the U.S. Air Force

- Tarwater, J. P.; Dulis, Edward J.; Wright Air Development Center; Crucible Steel Company of America, Investigation of Fe-Mn-Cr-N-C System for Heat Resistance and Oxidation Resistance Between 1200 F and 2000 F Wright Air Development Center, Air Research and Development Command, U.S. Air Force (1957).

- Bhat, Gopal K.; Philip, T. V.; Nehrenberg, Alvin E.; Steven, G.; Crucible Steel Company of America; Wright Air Development Center, United States. Wright Air Development Division. A Study of the Metallurgical Properties that are Necessary for Satisfactory Bearing Performance and the Development of Improved Bearing Alloys for Service Up to 1000 F. Defense Technical Information Center (1957).

- Crucible Steel Company of America; Moskovitz, A.; Redmerski, L., Corrosion of superalloys by selected fused salts Wright Air Development Division, Air Research and Development Command, U.S. Air Force (1960).

- Crucible Steel Company of America. Central Research Laboratory, Research on Workable Refractory Alloys of Tungsten, Tantalum, Molybdenun, and Columbium Aeronautical Systems Division, Air Force Systems Command, U.S. Air Force (1961).

See also

- Methods of steel production:

- Metallurgy cementation process

- Crucible steel processes

- Open-hearth furnace process, the Siemens-Martin process

- Steel industry

- Industry in Syracuse, New York.

Further reading

- Verhoeven, John D. (2007) Steel Metallurgy for the non-Metallurgist[62]

- Barney, Richard W.; Loveless, Robert W. (1995) How to Make Knives.[64] Krause Publications, Inc.

- Desvernine, Raoul Eugene, former president of Crucible. Democratic Despotism,[28][65] against the New Deal

History

- Darnall Works: built by Sanderson in 1835, and is part of a Scheduled Ancient Monument in Sheffield, England.

- George Naylor was the partner in the Naylor & Sanderson company. George Naylor, with his son-in-law Edward Vickers, founded the Vickers Limited steel foundry and the Naylor Vickers & Co. that cast church bells in 1854. Vickers Limited acquired The Barrow Shipbuilding Company and Maxim Nordenfelt Guns And Ammunitions Company, and built the Royal Navy's first submarine, Holland 1, and acquired the John Brown & Co. shipyard at Clyde, Scotland. Edward, with his sons William and Thomas Vickers (son-in-law of George Naylor), also formed Vickers, Sons & Company to produce marine shafts, propellers, armour plates, and artillery.

- Grace's Guide to British industrial history of Sanderson Brothers and Co.[13]

References

- ↑ "Crucible Location".

- ↑ Hannagan, Charley. "Crucible Industries LLC restarts Geddes steel mill". Syracuse.com. The Post-Standard. Retrieved August 8, 2014.

- ↑ "Crucible Industries Products".

- ↑ Hannagan, Charley (October 2009). "New Crucible owner says his company's in it for long haul". Syracuse.com. The Post-Standard. Retrieved August 2, 2014.

- ↑ Hannagan, Charley (October 23, 2009). "New owner closes on Crucible Specialty Metals plant". Syracuse.com. The Post-Standard. Retrieved July 30, 2014.

- 1 2 Hannagan, Charley (January 23, 2010). "Crucible Industries LLC signs partnership with German firm to sell steel globally". Syracuse.com. The Post-Standard. Retrieved August 2, 2014.

- 1 2 3 4 5 6 7 8 9 10 "A Timeline of Crucible Materials Corp.". Syracuse.com. The Post-Standard. 2009. Retrieved August 2, 2014.

- 1 2 3 4 5 Schramm, Carl, great-grandson of a Sanderson mill superintendent (June 1, 2014). "Why Immigration Is Crucial To The Revival Of America's Cities". Forbes.com. Forbes. Retrieved August 5, 2014.

- 1 2 3 4 Morrison, Janna (April 8, 2010). "Crucible Industries and Latrobe Specialty Steel Distribution Announce Partnership". FabricatingAndMetalWorking.com. Retrieved August 2, 2014.

- 1 2 3 4 Gilmer, Harrison (March 1953). "Birth of the American Crucible Steel Industry". Pennsylvania Historical Magazine. 36 (1): 17–36. Retrieved August 2, 2014.

- 1 2 "Crucible Steel, A technology war baby whose products are too numerous to count..." (Vol. XX, No. 5). Fortune magazine. November 1939. p. 75.

- 1 2 3 Inman, Donald. "Jones & Laughlin Steel". ReoCities.com. Beaver County Industrial Museum, Geneva College, Beaver Falls, Pennsylvania. Retrieved August 4, 2014.

- 1 2 3 4 "Sanderson Brothers and Co, steel manufacturers of Sheffield". GracesCuide.co.uk. June 18, 2014. Retrieved August 2, 2014.

- ↑ "Pittsburgh (Steel) Historical Marker, Behind the Marker". ExplorePAHistory.com. Retrieved August 2, 2014.

- 1 2 Union Trust Company of America announcement (July 8, 1900). "Crucible Steel Company of America, Underwriting Privilege". The Sun, New York.

- 1 2 "Former Sanderson's Darnall Steelworks and Don Valley Glassworks, Darnall Road, monument". English-Heritage.org. English Heritage. May 17, 2007. Retrieved August 8, 2014.

- 1 2 Clayton, professor, W. W. (1878). "History of Geddes, NY". Rays-Place.com. D. Mason & Co., Syracust NY. Retrieved August 8, 2014.

- 1 2 Kaufmann, Dwight W. (1986). Crucible, The Story of a Steel Company.

- ↑ Univ. of Toronto, Dept of Matallurgical Engineering (January 1, 1927). "The Crucible Steel Company of America". US.Archive.org. The Iron and Steel magazine. Retrieved August 8, 2014.

- ↑ Fruehan, Richard J., editor; 20+ authors. "The Making, Shaping and Treating of Steel". Scribd.com. AISE Steel Foundation, Pittsburgh, PA. Retrieved August 8, 2014.

- ↑ "Halcomb Steel Company". Syracuse Herald. Syracuse, New York. April 21, 1913.

- ↑ "The Iron Age". The Iron Age. 91 (12-18): 970. April 17, 1913.

- ↑ Kennedy, Richard; Roberts, George Adam (1998). Tool Steels (5th ed.). Materials Park, OH: ASM International. ISBN 1615032010.

- 1 2 3 Boccalini, M.; H. Goldenstein (February 2001). "Solidification of high speed steels" (PDF). International Materials Reviews. 46 (2): 92–107. doi:10.1179/095066001101528411. ISSN 0950-6608.

- ↑ "Big New Steel Plant; $7,500,000 Undertaking of Crucible Steel Company Near Pittsburg.". NYTimes.com. The New York Times. January 26, 1911. Retrieved August 4, 2014.

- ↑ Product Catalog, 1913 Edition, with a picture of the Sanderson works at Syracuse, New York.

- 1 2 3 4 "Crucible's New World". Newsweek. May 30, 1949.

- 1 2 Desvernine, Raoul Eugene (January 1, 1936). Democratic Despotism. New York: Dodd, Mead and Co. ASIN B000TCIHMC. Retrieved August 4, 2014.

- ↑ "A Pittsburgh Century (cont.), 1946–1960". Post-Gazette.com/. Pittsburgh Post-Gazette. Retrieved August 5, 2014.

- ↑ "Happy Ending, Crucible Steel gains goodwill by dropping "escape" clause". Business Week. February 24, 1951.

- ↑ Farol Metcalf, James. "Induction Heating, Molten Metal Eats Through and Explodes". Electric-History.com. Retrieved August 2, 2014.

- ↑ "Colt Steel begins closing its Crucible Steel Plant laying off 400". PittsburghWorldHerald.com. Pittsburgh World Herald. 1982. Retrieved August 8, 2014.

- ↑ Hannagan, Charley (May 2009). "Will bankruptcy give Crucible Materials Corp enough breathing room?". Syracuse.com. The Post-Standard. Retrieved August 2, 2014.

- 1 2 3 Hannagan, Charley (January 2010). "Crucible Industries LLC in Geddes partners with Pennsylvania steel firm". Syracuse.com. The Post-Standard. Retrieved August 2, 2014.

- ↑ Hannagan, Charley (November 2009). "Crucible Industries LLC ships first steel forged under new ownership". Syracuse.com. The Post-Standard. Retrieved August 2, 2014.

- ↑ "Crucible, Latrobe Specialty Steel Distribution Partner Up". IndustrialHeating.com. January 14, 2010. Retrieved August 2, 2014.

- ↑ "Model PT, CPM-S30V Powder Steel (Stainless)". StriderKnives.com. 2014. Retrieved August 3, 2014.

- ↑ "Knife Features, Types of Blade Steels". BuckKnives.com. Retrieved July 14, 2014.

- ↑ "Knife Blade Steels". KnifeSupply.com. Retrieved July 14, 2014.

- ↑ "Knife Blade Steel Types". TheKnifeConnection.net. Retrieved July 14, 2014.

- ↑ Covert, Pat. "CPM S35VN: Next Gen Exotic". Tactical-Life.com. Retrieved July 15, 2014.

- ↑ Hollis, Durwood (January 2011). "Steel, Steel, Everywhere! But Are You Choosing The Right Steel For You?". Guns magazine. Retrieved July 15, 2014.

- ↑ "Fusionwood 2.0 Blade Design". NewWestKnifeWorks.com. 2014. Retrieved July 15, 2014.

- ↑ Reed, J.D. (July 14, 1980). "On The Cutting Edge". Sports Illustrated. Retrieved October 3, 2011.

- ↑ Kertzman, Joe (2002). Sporting Knives: Folders, Fixed Blades, Pocket, Military, Gent's Knives, Multi-Tools, Swords (2 ed.). Krause Publications. p. 66. ISBN 978-0-87349-430-4.

- ↑ Gromer, Cliff (2002). "Art on the Cutting Edge". Field & Stream. 179 (6): 46.

- ↑ Delavigne, Kenneth (2004). Spyderco Story: The New Shape of Sharp. Colorado: Paladin Press. ISBN 1-58160-060-7.

- ↑ Pacella, Gerard (2002). 100 Legendary Knives, Iola, USA. Krause Publications. p. 145. ISBN 0-87349-417-2.

- ↑ Ewing, Dexter (2013). "Factories Drink From the Custom Maker Well". In Joe Kertzman. Knives 2014: The World's Greatest Knife Book (34 ed.). Iola, Wisconsin: F+W Media. pp. 42–46. ISBN 978-1-4402-3700-3.

- ↑ Dockery, Kevin (2004). Weapons of the Navy SEALs. California: Berkeley Hardcover. pp. 23–24. ISBN 0-425-19834-0.

- ↑ Piccione, Editor, Guns & Gear, Mike (May 13, 2013). "Navy SEAL auctions knife from bin Laden raid – UPDATE – SOLD – $35,400!". The Daily Caller. Retrieved August 1, 2014.

- ↑ Chris DiStefano; Leopold Ketel (May 17, 2005). "Benchmade Wins 2005 Knife of the Year Award". Press releases.

- ↑ "Knife of the Year Award". ShootingIndustry.com. Shooting Industry. Retrieved August 7, 2014.

- 1 2 Pacella, Gerard (2002). 100 Legendary Knives. Krause Publications. p. 126. ISBN 0-87349-417-2.

- ↑ Mickadeit, Frank (September 10, 2009). "Phill, Phil want Marines to be sharp". Orange County Register. Retrieved August 3, 2014.

- ↑ Hartsfield, Phill (1995), "Live Swords", International Shinkendo Newsletter Volume 1, Issue 3.

- ↑ Dumm, Chris (January 27, 2014). "Knife Review: Kershaw Blur S30V". Retrieved August 2, 2010.

- 1 2 "CPM S30V Data Sheet" (PDF). Crucible Industries LLC. Archived from the original (PDF) on October 11, 2010. Retrieved August 2, 2014.

- ↑ "CPM S35V Data Sheet" (PDF). Crucible Industries LLC. Retrieved August 2, 2014.

- ↑ "Crucible 154CM Data Sheet" (PDF). Crucible Industries LLC. Retrieved August 3, 2014.

- ↑ "Crucible A2 Data Sheet" (PDF). Crucible. Retrieved July 14, 2014.

- 1 2 Verhoeven, John D. (2007). Steel Metallurgy for the non-Metallurgist. ASM International.

- 1 2 John A. Ricketts, Ispat Inland, Inc.; ATSI Engineering Services, "An Introduction to Blast Furnace Technology" (2014). "How A Blast Furnace Works". American Iron and Steel Institute. Retrieved August 2, 2014.

- ↑ Barney, Richard W.; Loveless, Robert W. (1995). How to Make Knives. Krause Publications, Inc. ISBN 978-0873413893. Retrieved August 8, 2014.

- ↑ Desvernine, Raoul Eugene (May 1, 2006). Democratic Despotism, reprint. New York: Kessinger Publishing. Retrieved August 4, 2014.

Bibliography

- Gilmer, Harrison, Birth of the American Crucible Steel Industry (1953).

- Harrison Gilmer's primary reference: Bwank, James Moore, History of the Manufacturing of Iron in All Ages (1892); publisher: American Iron and Steel Association, Philadelphia, Pennsylvania

- Kaufmann, Dwight W., Crucible, The Story of a Steel Company (1986).

- Kennedy, Richard; Roberts, George Adam (1998). Tool Steels (5th ed. ed.). Materials Park, OH: ASM International. ISBN 1615032010.

External links

![]() Media related to Metallurgy at Wikimedia Commons

Media related to Metallurgy at Wikimedia Commons

-

Learning materials related to Topic:Metallurgical engineering at Wikiversity

Learning materials related to Topic:Metallurgical engineering at Wikiversity - Crucible Products

- Crucible distributors: