Borehole mining

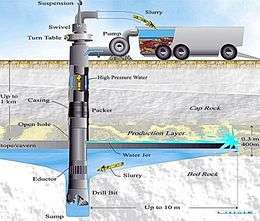

Borehole Mining (BHM) is a remote operated method of extracting (mining) mineral resources through boreholes by means of high pressure water jets. This process can be carried-out from land surface, open pit floor, underground mine or floating platform or vessel through pre-drilled boreholes.

The process

- A borehole is drilled from land surface to a desired depth, where then actual borehole mining will take place.

- A casing column is lowered down the hole. Since BHM takes place in an "open hole", the casing shoe is located just above the upper border of the production interval (ore body) leaving the rest open.

- The BHM tool is lowered into the hole.

Description of a BHM tool

The tool consists of at least two concentric pipes which are forming two hydraulic channels - one for pumping down a high-pressure working agent (water) and second for delivering pregnant slurry back to the surface. A BHM tool usually has (down-up): an eductor (waterjet pump) section, a hydromonitor section, an extension section and a hub, connecting it all to a drill pipe string. This string extends the tool up to the surface. Above the surface, the tool has a swivel allowing its suspension and rotation in a hole, and also connections to the working agent supply (pump station) and a slurry collector. A drill rig is normally required to operate a BHM tool.

The tool is lowered into a well until the hydromonitor reaches the required depth where the actual borehole mining is started. Then the high-pressure water is pumped down and receives back productive slurry. In the collecting pond or tank, slurry is separated and clarified water is pumped down for re-circulating.

While extracting of material, different shape underground caverns could be created. Their shapes depend on the BHM tool manipulation while mining, which obviously consist of the tool rotation, sliding it up and down and combination of these two movements. Borehole mining is applied from vertical, horizontal and deviated wells.

Advantages of BHM

The main advantages of BHM include its low capital cost, mobility, selectivity, ability to work in hazardous and dangerous conditions and low environmental impact. The method has been used in mining of such natural resources and industrial materials as: uranium, iron ore, quartz sand, gravel, coal, poly-metallic ores, phosphate, gold, diamonds, rare earths, amber and several more. Borehole mining is also used in exploration, oil, gas and water stimulation, underground storage construction and drainage.