Automatic Lubricator

An automatic lubricator, is a device fitted to a steam engine to supply lubricating oil to the cylinders and, sometimes, the bearings and axle box mountings as well.[1] There are various types of automatic lubricator, which include various designs of displacement, hydrostatic and mechanical lubricators.

Displacement lubricator

Ramsbottom type

The displacement lubricator was introduced in the United Kingdom in 1860 by John Ramsbottom. It operates by allowing steam to enter a closed vessel containing oil. After condensing, the water sinks to the bottom of the vessel, causing the oil to rise and overflow into delivery pipes. The oil from the delivery pipes is introduced into the steam pipe, where it is atomised and carried to the valves and cylinders.

In early applications in steam locomotives, either two displacement lubricators (one for each cylinder) would be positioned at the front of the boiler near the valves, often on either side of the smokebox or one lubricator would be placed behind the smokebox. The behind smokebox configuration has the advantage that a good connection can be made to the steam pipe and was used by the Great Western Railway. It has the disadvantage that the lubricator's accessibility is reduced and additional drain pipes are required to be connected to the waste to avoid it dripping onto the boiler.[2]

Later types of lubricator (from around 1887[2]), referred to as the "sight-feed" type, allowed a sight glass to be positioned in the cab where the rate of oil feed could be observed.

The displacement lubricator was a useful stop-gap but had the disadvantage that it was difficult to accurately control over the rate of oil feed and lubrication was only supplied when the engine was doing work (when a locomotive is coasting with the regulator closed, no steam is present to operate the lubricator). In the Ramsbottom type the flow of lubricant depended mainly on the weather. In cold weather the rate of feed would increase because steam would condense more rapidly.

Roscoe type

The Roscoe type lubricator improved the situation by providing a valve with which to regulate the flow of steam and hence lubricant. Setting the valve correctly required experience and depended on the speed of the train.[2]

The Roscoe lubricator was invented by James Roscoe in 1862 and patented in British Patent 1337. It incorporated two improvements over the original Ramsbottom type, the ability to control the quantity of steam which entered the lubricator, via a control valve, and the addition of an air filled chamber within the oil reservoir. The chamber expanded when steam was cut off, the aim of which was to supply oil even when the locomotive was coasting. However, this proved ineffective in practice, particularly if the locomotive was coasting for a long time (e.g. down a hill).[2]

Replacement

When more sophisticated lubricators, such as the Wakefield and Detroit types, were developed, displacement lubricators fell out of use but they are still used on model steam engines.[3]

Wakefield lubricator

This was patented by Charles Wakefield in the 1890s.[4]

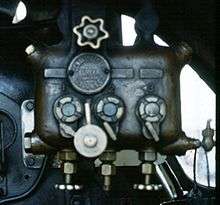

Detroit hydrostatic lubricator

This type of hydrostatic displacement lubricator was made by the Detroit Lubricator Company of the USA. A British patent was granted in 1911 and this lubricator was then manufactured by the Vacuum Oil Company (later Mobil Oil) as the British Detroit Lubricator.[5] This lubricator was commonly made with either 3,4 or 5 feeds, the center feed on the odd numbered lubricators was often used for supplying oil to the steam end of Westinghouse Air compressors.

The one piece lubricator body is a gunmetal casting and incorporates the condensing chamber, the oil reservoir and the sight glasses. Passages within the body interconnect these areas. The body is fitted with a steam valve, a water valve, an oil control valve. Sight glasses are fitted at the front & back of the body on each of the feeds, these feeds are fitted with individual feed regulating valves for controlling the feed rate for each outlet. The oil control valve was used to either turn the supply off/on, or to shut off the supply to the cylinders and just supply the air compressor with oil whilst the locomotive is stationary on lubricators with a center feed. Each feed is also fitted with a drain valve for cleaning each sight glass. The body is also fitted with an oil chamber drain for draining the condensed water from the oil chamber.[5]

Silvertown mechanical lubricator

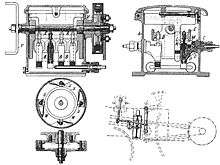

The Silvertown lubricator was designed and developed by the Midland Railway in 1911 and from 1922 was commercially available from Gresham and Craven. This style of mechanical lubricator was used by the London, Midland and Scottish Railway and latter by British Rail, as well as by the various UK private locomotive builders for export overseas. Commonly 2 lubricators were fitted, one for lubricating the cylinders and the second for lubricating the axleboxes.[5]

The lubricator is a self-contained unit with the drive mechanism fitted at one end, with the drive shaft running through the cast iron oil reservoir. The drive shaft is fitted with 2 hardened steel eccentrics which provide movement to the drive frame which runs in machined grooves in the oil reservoir. This drive frame reciprocates vertically which then drives the double acting independent oil pumps located in the oil reservoir.[5]

The lubricator is driven by a rod from the expansion link in locomotives valve gear. The rocking motion of this drive is converted to a rotary motion by a series of driving pawls contained in a clutch box. The lubricators were also fitted with a priming hand wheel on the outer face of the lubricator.[5]

Friedmann/ Nathan mechanical lubricator

The Friedmann system of mechanical lubricators included the DV & FSA type lubricators. This style of mechanical lubricator was designed & produced by Alex Friedmann KG of Austria. The DV type were then made under licence by in the US by the Nathan Manufacturing Co. & the type DV & FSA types in the UK by Davies & Metcalfe Ltd..[5]

Both types of lubricator are of the 'valveless' type, having no ball valves, springs or oil seals used in the operation of the pump units.[5]

The DV range was available in range of sizes with capacities ranging from 8 to 36 pints, and the number of feeds from 1 to 26. Each of the lubricators consist of a reservoir, a ratchet assembly, a sliding shaft assembly, and the pump units. A screwed oil filler cap is fitted to the lockable hinged lid of the reservoir and a sight glass for indicating the oil level is fitted to the front face of the reservoir. The pumps of the DV type lubricator are operated by a sliding shaft assembly, unlike the Silverton or Wakefield lubricators which are operated by a rotating camshaft.[5]

The FSA type lubricator differs by each pump having two separate pistons to control the pumping & distribution of oil. The pistons are driven by cams on the driving shaft. The driving shaft is driven via a means of a roller ratchet assembly which converts the reciprocating motion of the operating linkage to rotary motion.[5]

See also

References

- ↑ "Lubrication". Handbook for steam locomotive enginemen. London: British Transport Commission. 1957. pp. 126–128. OCLC 505163269.

- 1 2 3 4 Lubrication of Locomotives, B.L. Ahrons 1922, The Locomotive Publishing Co. Ltd.

- ↑ "Archived copy". Archived from the original on 2011-10-06. Retrieved 2009-01-09.

- ↑ "Archived copy". Archived from the original on 2009-05-17. Retrieved 2009-01-09.

- 1 2 3 4 5 6 7 8 9 Steam Locomotive Lubrication its Development and Practice, Peter W.Skellon 1997, MIC Publications ISBN 0-9530417-0-0

External links

| Wikimedia Commons has media related to Steam engine lubricators. |