Amorphous solid

| | Unsolved problem in physics: What is the nature of the glass transition between a fluid or regular solid and a glassy phase? What are the physical processes giving rise to the general properties of glasses? (more unsolved problems in physics) |

| Condensed matter physics |

|---|

|

| Phases · Phase transition · QCP |

|

Phase phenomena |

|

Electronic phases |

|

Electronic phenomena |

|

Magnetic phases |

|

Scientists Van der Waals · Onnes · von Laue · Bragg · Debye · Bloch · Onsager · Mott · Peierls · Landau · Luttinger · Anderson · Van Vleck · Mott · Hubbard · Shockley · Bardeen · Cooper · Schrieffer · Josephson · Louis Néel · Esaki · Giaever · Kohn · Kadanoff · Fisher · Wilson · von Klitzing · Binnig · Rohrer · Bednorz · Müller · Laughlin · Störmer · Tsui · Abrikosov · Ginzburg · Leggett |

In condensed matter physics and materials science, an amorphous (from the Greek a, without, morphé, shape, form) or non-crystalline solid is a solid that lacks the long-range order characteristic of a crystal. In some older books, the term has been used synonymously with glass. Nowadays, "Glassy solid" or "Amorphous solid" is considered to be the overarching concept, and glass the more special case: A glass is an amorphous solid that exhibits a glass transition.[1] Polymers are often amorphous. Other types of amorphous solids include gels, thin films, and nanostructured materials such as glass.

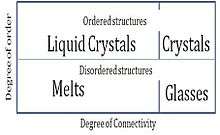

Amorphous materials have an internal structure made of interconnected structural blocks. Whether a material is liquid or solid depends primarily on the connectivity between its elementary building blocks so that solids are characterized by a high degree of connectivity whereas structural blocks in fluids have lower connectivity (see figure on amorphous material states).[2]

Nano-structured materials

Even amorphous materials have some shortrange order at the atomic length scale due to the nature of chemical bonding (see structure of liquids and glasses for more information on non-crystalline material structure). Furthermore, in very small crystals a large fraction of the atoms are the crystal; relaxation of the surface and interfacial effects distort the atomic positions, decreasing the structural order. Even the most advanced structural characterization techniques, such as x-ray diffraction and transmission electron microscopy, have difficulty in distinguishing between amorphous and crystalline structures on these length scales.

Amorphous thin films

Amorphous phases are important constituents of thin films, which are solid layers of a few nm to some tens of µm thickness deposited upon a substrate. So-called structure zone models were developed to describe the micro structure and ceramics of thin films as a function of the homologous temperature Th that is the ratio of deposition temperature over melting temperature.[3][4] According to these models, a necessary (but not sufficient) condition for the occurrence of amorphous phases is that Th has to be smaller than 0.3, that is the deposition temperature must be below 30% of the melting temperature. For higher values, the surface diffusion of deposited atomic species would allow for the formation of crystallites with long range atomic order.

Regarding their applications, amorphous metallic layers played an important role in the discussion of a suspected superconductivity in amorphous metals.[5] Today, optical coatings made from TiO2, SiO2, Ta2O5 etc. and combinations of them in most cases consist of amorphous phases of these compounds. Much research is carried out into thin amorphous films as a gas separating membrane layer.[6] The technologically most important thin amorphous film is probably represented by few nm thin SiO2 layers serving as isolator above the conducting channel of a metal-oxide semiconductor field-effect transistor (MOSFET). Also, hydrogenated amorphous silicon, a-Si:H in short, is of technical significance for thin film solar cells. In case of a-Si:H the missing long-range order between silicon atoms is partly induced by the presence by hydrogen in the percent range.[7]

The occurrence of amorphous phases turned out as a phenomenon of particular interest for studying thin film growth.[8] Remarkably, the growth of polycrystalline films is often used and preceded by an initial amorphous layer, the thickness of which may amount to only a few nm. The most investigated example is represented by thin multicrystalline silicon films, where such as the unoriented molecule. An initial amorphous layer was observed in many studies.[9] Wedge-shaped polycrystals were identified by transmission electron microscopy to grow out of the amorphous phase only after the latter has exceeded a certain thickness, the precise value of which depends on deposition temperature, background pressure and various other process parameters. The phenomenon has been interpreted in the framework of Ostwald's rule of stages[10] that predicts the formation of phases to proceed with increasing condensation time towards increasing stability.[5][9] Experimental studies of the phenomenon require a clearly defined state of the substrate surface and its contaminant density etc., upon which the thin film is deposited.

References

- ↑ J. Zarzycki: Les verres et l'état vitreux. Paris: Masson 1982. English translation available.

- ↑ M.I. Ojovan, W.E. Lee. Connectivity and glass transition in disordered oxide systems. J. Non-Cryst. Solids, 356, 2534-2540 (2010). doi:10.1016/j.jnoncrysol.2010.05.012

- ↑ B. A. Movchan & A. V. Demchishin (1969). "Study of the structure and properties of thick vacuum condensates of nickel, titanium, tungsten, aluminium oxide and zirconium dioxide". Phys. Met. Metallogr. 28: 83–90.

- ↑ J.A. Thornton (1974). "Influence of apparatus geometry and deposition conditions on the structure and topography of thick sputtered coatings". Journal of Vacuum Science and Technology. 11 (4): 666–670. Bibcode:1974JVST...11..666T. doi:10.1116/1.1312732.

- 1 2 Buckel, W. (1961). "The influence of crystal bonds on film growth". Elektrische en Magnetische Eigenschappen van dunne Metallaagies. Leuven, Belgium.

- ↑ R.M. de Vos; H. Verweij (1998). "High-Selectivity, High-Flux Silica Membranes for Gas Separation". Science. 279 (5357): 1710–1. Bibcode:1998Sci...279.1710D. doi:10.1126/science.279.5357.1710. PMID 9497287.

- ↑ "Glaserei Knoke - Ihr Glaser in Hannover". glaserei-knoke.de. Retrieved 26 November 2016.

- ↑ Magnuson et al. Electronic Structure and Chemical Bonding of Amorphous Chromium Carbide Thin Films; J. Phys. - Cond. Mat. 24 , 225004 (2012).

- 1 2 M. Birkholz; B. Selle; W. Fuhs; S. Christiansen; H. P. Strunk & R. Reich (2001). "Amorphous-crystalline phase transition during the growth of thin films: the case of microcrystalline silicon" (PDF). Phys. Rev. B. 64 (8): 085402. Bibcode:2001PhRvB..64h5402B. doi:10.1103/PhysRevB.64.085402.

- ↑ W. Ostwald (1897). "Studien über die Umwandlung fester Körper". Z. Phys. Chem. 22: 289–330.

Further reading

- R. Zallen (1969). The Physics of Amorphous Solids. Wiley Interscience.

- S.R. Elliot (1969). The Physics of Amorphous Materials (2nd ed.). Longman.

- N. Cusack (1969). The Physics of Structurally Disordered Matter: An Introduction. IOP Publishing.

- N.H. March; R.A. Street; M.P. Tosi, eds. (1969). Amorphous Solids and the Liquid State. Springer.

- D.A. Adler; B.B. Schwartz; M.C. Steele, eds. (1969). Physical Properties of Amorphous Materials. Springer.

- A. Inoue; K. Hasimoto, eds. (1969). Amorphous and Nanocrystalline Materials. Springer.

External links

- Journal of non-crystalline solids (Elsevier)